ToolTrack MES

About ToolTrack MES

ToolTrack MES Pricing

If you would like to learn about our software, please visit www.i-trackcorp.com

Starting price:

$2,500.00 per month

Free trial:

Not Available

Free version:

Not Available

Other Top Recommended Manufacturing Software

Most Helpful Reviews for ToolTrack MES

1 - 5 of 12 Reviews

Emeka

Verified reviewer

Higher Education, 501-1,000 employees

Used daily for less than 12 months

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed October 2018

This software is great for improving operations and visibility in manufacturing/assembly processes.

ToolTrack has a lot of functionality at a great price and with great customer support.

CONSThere is nothing I do not like about this software.

Dietmar

Consumer Goods, 201-500 employees

Used daily for more than 2 years

OVERALL RATING:

5

EASE OF USE

4

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed July 2016

Itrack MES review

When we decided to move our manufacturing processes from Contract Manufacturers to our captive facility we needed an MES to obtain visibility of the activity on the production floor. We assemble opto-electronic components using semiconductor assembly tools. Yield and throughput is critical as is material trace-ability and serialization. I was familiar with some of the larger commercially available MES and EPR systems but from prior experience was aware of the software maintenance these systems required. I came across Itrack and was pleasantly surprised by the minimal support requirements, ease of set-up and ease of maintenance and ease of adaptability to our processes. We have been using Itrack for 3+ years are are continuing to implement additional functionality as our business requirements change.

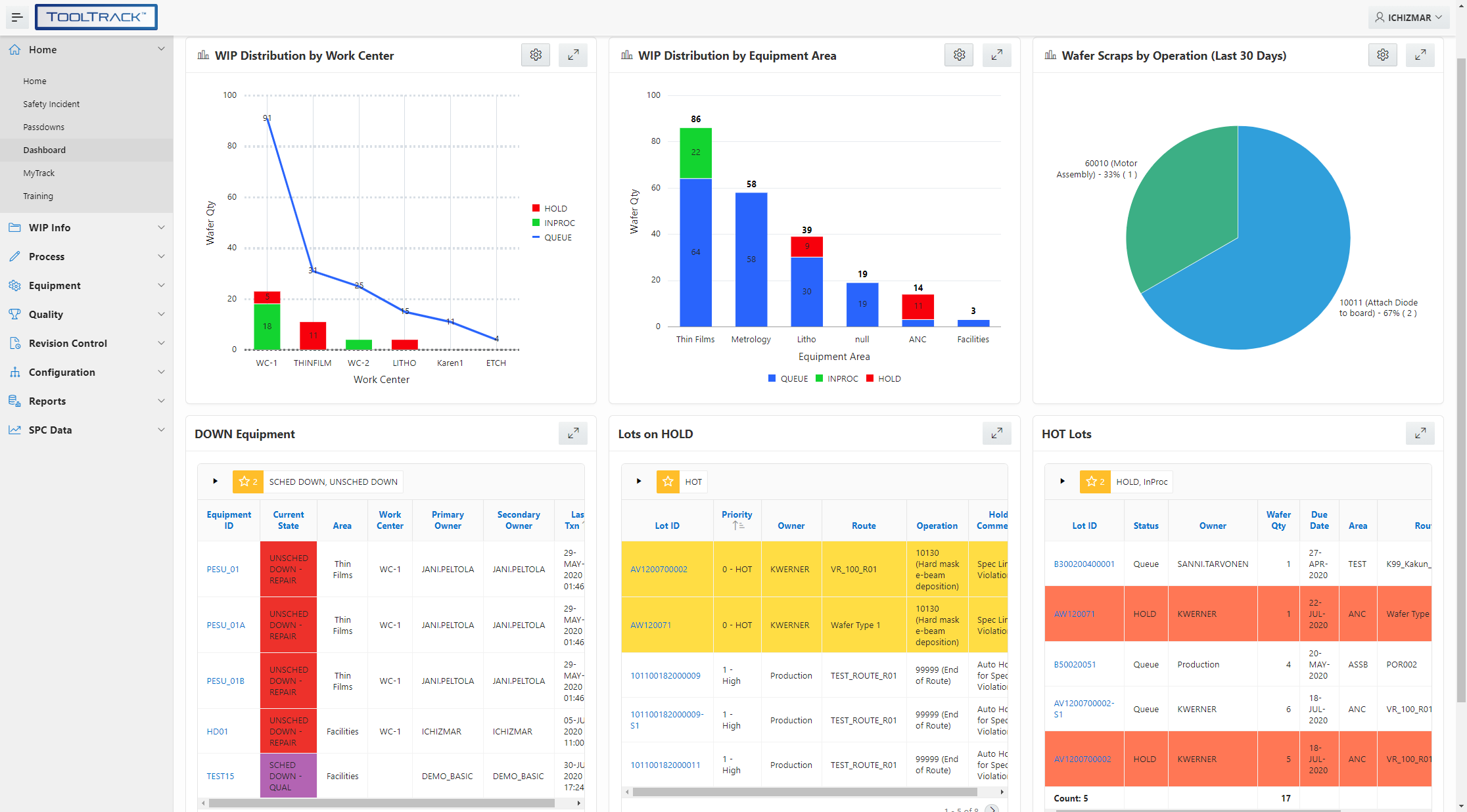

PROSThe software provides real time information. In a fast paced manufacturing environment defects or miss-processes are costly and impact large amount of work-in-progress. Itrack provides visibility and enables decision making. The Dashboards can be set up for shop-floor supervisor / lead level with detailed tactical lot information as well as set up for the executive level with aggregated view by product families, as well as anywhere in between. The system is flexible and adaptable to many manufacturing industries where material trace-ability, yield, efficiency and equipment utilization are critical to the companies success.

Michael

Electrical/Electronic Manufacturing, 51-200 employees

Used daily for less than 6 months

OVERALL RATING:

4

EASE OF USE

4

VALUE FOR MONEY

5

CUSTOMER SUPPORT

4

FUNCTIONALITY

4

Reviewed March 2017

Gets the job done

We are using this for document control. We're able to maintain historical copies, route changes for approval, and assure only the current version is readily available. Notifications can be set up tailored to people's roles and responsibilities. It's no Agile document control system, but gets the job done and has a very easy learning curve.

PROSEase of use. Easy learning curve.

Brian

Electrical/Electronic Manufacturing

Used daily for less than 12 months

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed March 2017

Best MES I've used

I've used multiple MES Platforms for microelectronics manufacturing and R&D applications as an Engineer. I've also evaluated several for purchase. ToolTrack takes the cake for being good at all of it - even over the ones costing orders of magnitude more. Has the rare duality of being flexible enough for R&D tracking/processing, yet still user-friendly on the manufacturing floor. Scalability is another strong point - for a startup or small business, ToolTrack serves as a capable and cost-friendly system which can easily scale as your company grows. I've found MES entry to be difficult for a startup or small company - if you buy a system you can afford early, it likely won't scale as the company grows, and switching MES's is never fun. But a large-scale MES too early is too expensive, cumbersome and inflexible. Wait too long to get an MES, and you've likely kludged a home-grown 'system'. Finally, the support is fantastic - the folks at I-Track have years of experience in high volume manufacturing and R&D environments, and are eager to help solve your problems. And they are pleasant (even fun!) to work with.

PROSUsability, flexibility, cost, support. Everything I need and nothing I don't, at a very reasonable price.

CONSNone, really - anything that you don't like or that doesn't seem to work well for you can easily be changed for you!

Brian

Electrical/Electronic Manufacturing

Used less than 12 months

OVERALL RATING:

4

EASE OF USE

4

CUSTOMER SUPPORT

4

FUNCTIONALITY

4

Reviewed April 2016

Control of volume manufacturing optical electronics

A user friendly interface for managing raw materials consumption into sub assemblies and then the final product. The ability to create and configure our business and product specific data, via a Super User back end in real time, without having to log a request with the developers. The options available within I-Track to view reports and access to all of the data for easy download of CSV files. Ian clearly has an understanding of manufacturing and process control, which helps considerably when we are discussing and developing Continuous Improvements for the business.

CONSThe core product itself, and the requirements given by the business to I-Track at the beginning, have given the business what we have asked for so far - so no problems there. One area that would help the business would be a quicker turn around for enhancement / development requests. As an individual, I can understand how some tasks can be time consuming and workload requests can pile up. The business leaders however, expect requests and solutions to be delivered in a quick turnaround time. Having said that, Ian is always supportive and positive with his dealings with us.