Senseye PdM

About Senseye PdM

Senseye PdM Pricing

Contact Senseye for pricing details.

Starting price:

$7.50

Free trial:

Not Available

Free version:

Not Available

Other Top Recommended CMMS Software

Most Helpful Reviews for Senseye PdM

1 - 5 of 5 Reviews

Dylan

Packaging and Containers, 10,000+ employees

Used daily for less than 12 months

OVERALL RATING:

5

EASE OF USE

4

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed June 2021

Senseye PdM

As a result of the successful implementation of the Senseye PdM system at Jupiter Road, a number of potential breakdowns were avoided. With the support of the system, lost time has been avoided by completing preventative maintenance during periods of scheduled downtime, prior to the degradation and catastrophic failure of an asset. Further to the system’s ability to detail the issues with the site’s assets, it has also been used to confirm if the machines are in good health – and how exactly they operate under various conditions. This assurance has helped the team to confidently run the corrugator, to maximise production output.

PROSThe following features have been used most effectively within Smurfit Kappa: - Compare Dashboards - Thresholds and Prognostics - Trend and anomaly detections

CONSThe system performs a 120 hour learning period for each asset that in on-boarded to the system. In this time, the system 'learns' what the 'normal' operating levels (vibration and current) are for each unique asset. If an asset is in poor condition when the system is installed, however, the system learns that the poor condition is the normal condition.

Reasons for switching to Senseye PdM

Overall, the Senseye PdM system has the ability to provide a deeper understanding of the assets – with the potential to view and evaluate data on a live and continuous basis. The system has scope for complete integration with the sites’ daily engineering function, helping to maximise performance.

David

Mining & Metals, 10,000+ employees

Used weekly for less than 2 years

OVERALL RATING:

4

EASE OF USE

3

FUNCTIONALITY

4

Reviewed June 2021

use of Senseye within the steel industry

One of the strongest elements of Senseye is the team behind it, they have worked well with our team in integrating and moulding Senseye to work in the hugely varying environment of the steel industry.

PROSSenseye as an application is important to the future of industries like steel, where margins are tight and resources are limited. This sort of predictive application will be critical to the success of the industry as it will give us confidence in the condition of our assets and allow us, along with the use of other condition systems, to carry out targeted maintenance based on the actual condition of our assets. This will have a significant benefit to the availability of our assets and minimise unplanned outages.

CONSI find the user interface to be a bit 'clunky' , if it could be easier to get to the issue and get the feedback in a slicker way that would make it much easier. As mentioned the notification system needs to be developed to notify by exception, and also look at different ways to send the notifications.

Reason for choosing Senseye PdM

Because it seemed the ideal solution that fitted in with my strategy for my area and they were prepared to work with us to make it work.

Jan

Machinery, 1,001-5,000 employees

Used weekly for less than 2 years

OVERALL RATING:

4

EASE OF USE

5

VALUE FOR MONEY

3

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed June 2021

Using Senseye in a CNC machining context

despite not having reached the results we needed I would still recommend their tool as long as you have made sure the Q of the data is adequate and able to pinpoint the failure you try to predict. It is not a magic system that sees failures out of any data, as it is often sold.

PROSthe ease of integration and setup. the easy to use application The support and friendly nature of the team @ Senseye

CONSnot getting the results we needed and it seems to have been over promised at sales pitches

Reason for choosing Senseye PdM

executive decision after winning a pitch event with competitors

Andy

Mechanical or Industrial Engineering, 2-10 employees

Used monthly for less than 2 years

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed September 2019

Intuitive Senseye Software Scales Your Predictive Maintenance

I was aware of Senseye as a software application to scale prediction in industry and came across users when I was training front line engineers at Nissan UK, Senseye was new to them and like most they were not open to change. That soon turned around when we started seeing real results coming in as the Senseye software gained more data insights that they could see resulting in avoiding unplanned events. I've found it very easy to navigate and as a former predictive practitioner could see the enormous benefits that scaling PdM brings; this was something we could only dream of just ten years ago!

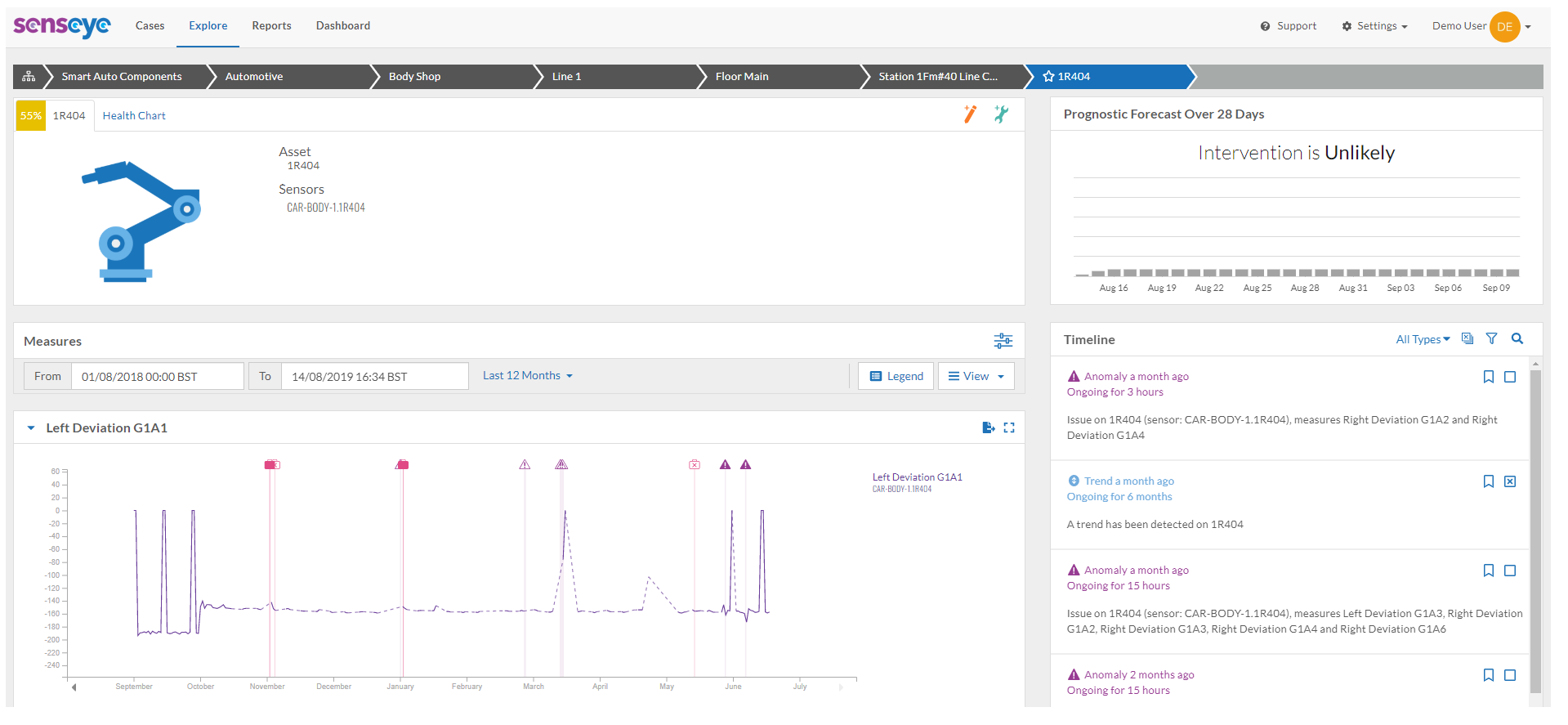

PROSThe intuitive dashboard is excellent for front line users to gain insights quickly and direct their attention to the important few assets thereby freeing up their limited resources. The feedback loop via the maintainers dashboard is great to alert the support team at Senseye of the type of anomalies found, this information then leverages the power of their machine learning algorithms to get from Predictive to Prognostic.

CONSMost of my experience is around the front end where the engineers and maintainers interact with the dashboard. The latest iteration has improved over time to fit the end users needs and become more intuitive. All of my concerns of a couple of years ago have now been improved due to the excellent support team at Senseye. It's great that they have engineers with predictive technology backgrounds that understand the challenges that users face daily in an industrial environment.

Tim

Chemicals, 10,000+ employees

Used daily for less than 12 months

OVERALL RATING:

4

EASE OF USE

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed June 2021

Great system that gievs me a good overview of the condition of motors and gearboxes

Great so far and as we implement more features it is becoming more impressive

PROSThe alert system that points me to the problem areas is invaluable, also the fact that i can scan over all the motors and gearboxes on my line without having to test each one individually is brilliant

CONSId Like to be able to see the condition of all motors and gearboxes on one page as a quick glance rather than scrolling down a list