aPriori

About aPriori

aPriori Pricing

Please contact aPriori directly for pricing information.

Starting price:

$1.00 per year

Free trial:

Available

Free version:

Not Available

Other Top Recommended Manufacturing Software

Most Helpful Reviews for aPriori

1 - 5 of 95 Reviews

Carolyn

201 - 500 employees

Used less than 6 months

OVERALL RATING:

4

Reviewed April 2023

aPriori for Design Engineers

Anonymous

5,001-10,000 employees

Used daily for less than 2 years

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed November 2020

Definitely a tool you need in your tool kit

As a customer, our aPriori representatives have been very helpful and quick to respond. Coming from a different software, I have found aPriori is easy to use and intuitive.

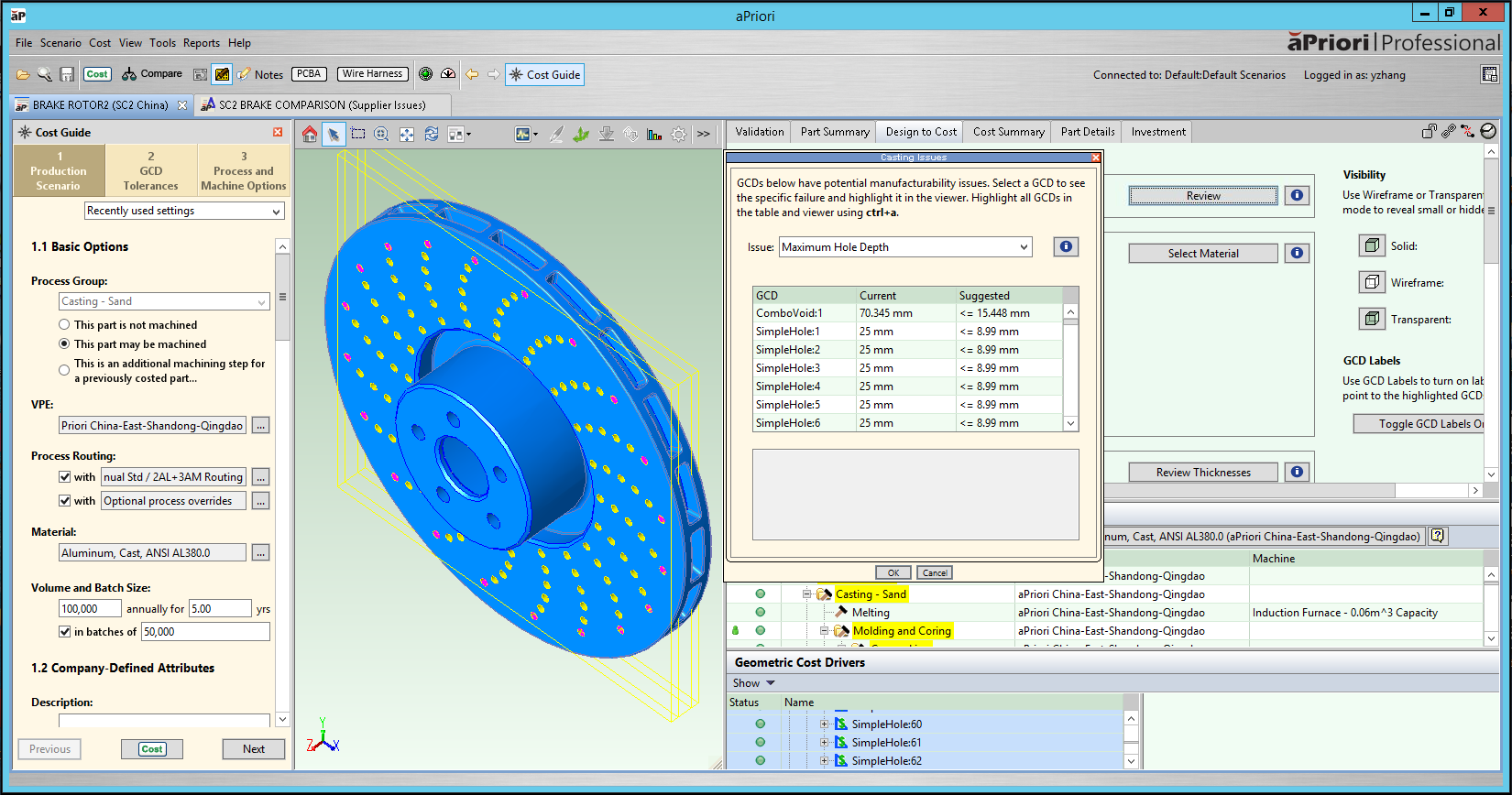

PROSI like how aPriori is easy to use and the interface is friendly. Running scenarios is quick and easy and I like the built in feature where aPriori can analyze and figure out the proper machining for you if you don’t know what would be used.

CONSAt least for my application, I would like more customization on changing which holes/features are exempt from certain processes (i.e. the part is anodized everywhere except certain holes etc).

Reasons for switching to aPriori

Change in companies

Gimble

Consumer Electronics, 5,001-10,000 employees

Used daily for more than 2 years

OVERALL RATING:

5

EASE OF USE

4

VALUE FOR MONEY

4

CUSTOMER SUPPORT

4

FUNCTIONALITY

5

Reviewed November 2020

Powerful cost tool for physical parts cost analysis

It helps us deliver product leadership. For the NPI project, we have high confidence when negotiating with the supplier for the low-cost delivery. For existing products, we use this costing tool for apple_to_apple comparison between our product and competitor and then generate cost-saving ideas from a design perspective.

PROSThis software is an excellent cost tool with the cost evaluation capability for not only CAD models but also physical parts. Based on five_year end-user experience, the user guide costing function module has sufficient flexibility and allow the users to develop and customize the process routing in term of specific products. Also, the bulk costing function does help us to proceed with the batch part costing analysis in high efficiency. We always need to conduct the costing for the condenser, evaporator, motor that is fabricated with many stamping and tube parts with complicated assembly operation inclusion. For these components, there is no standard template in the cost tool. So we develop the cost models with user-guided costing methodology and integrated with bulk cost function to conduct these assemblies cost, following this approach, we deliver very high-quality cost data with significant time_consumtion eventually.

CONSFrom my practice, I think a simple GUI is needed to have the filter capability to quickly select or pick secondary processes based on process group and material selected.

Riley

Design, 10,000+ employees

Used monthly for more than 2 years

OVERALL RATING:

2

EASE OF USE

1

VALUE FOR MONEY

1

CUSTOMER SUPPORT

3

FUNCTIONALITY

4

Reviewed August 2022

Honest Apriori Review

Poor. I have high hopes for the tool but it needs to become more user friendly as advertised and the output needs to get closer to actual cost. Right now I can't trust the quote from the tool or use it in any meaningful way. The best part of it is for concept parts at the moment to decided between two different designs.

PROSI like that I can quickly compare two prototype concepts and get a relative cost difference. I also see the value in having a software that could be easy to use and dump a part in to get cost in a few clicks.

CONSI think there is a huge gap in actual cost vs apriori cost. I don't think it is as user friendly as advertised. The software has odd quirks and poorly set defaults on the interface. If a cost is off, there are too many parameters to check to understand why, which requires advanced users to troubleshoot. The VPE doesn't get updated often enough. I can't cost painted parts. The weld tool is junk, hard to use and takes too long. Weldments always quote way off of actual cost. Special materials are not in the list unless manually added. Our common steel types are not set as default so I have to search for them in the list each time. It would be nice if the material could pull in automatically from Creo. I have been told the tool can help save cost by recommending better thicknesses, clearance hole sizes, or tolerances, but these are chosen based on our standards and best practices so I have not seen any valuable cost reductions from recommended geometry changes. The material nesting tool is totally inaccurate because our manufacturing group uses their own software to nest laser cut parts. Sometimes it chooses the wrong default manufacturing processes because it is looking for the cheapest way to make a part but not how we actually would. Ex. I've seen laser cut parts default to water jet and we don't have that capability so I have to go in and manually change the process. The costs for piece parts are starting to approach actual cost but assemblies are way off.Im out of characters

Cassandra

Airlines/Aviation, 10,000+ employees

Used daily for less than 12 months

OVERALL RATING:

5

EASE OF USE

4

FUNCTIONALITY

5

Reviewed November 2020

Great tool for cost negotiation

I like the ability to modify details the VPEs and processes to more accurately model unique processes and specific features of complex parts. I also like how aPriori very clearly indicates which features are driving your overall cost, through the cost breakdown and part summary. When discussing parts with engineering and with suppliers, it is incredibly useful to be able to drill down to specific operations and have discussions around tangible times and costs. It is also very helpful to distinguish between cycle time and setup time as this helps to highlight part volume as a cost driver.

CONSThe software sometimes has difficulty adjusting to different monitor resolutions (especially very high resolution monitors which use a default zoom) which results in menus being cut off and difficult to navigate ( I am able to resolve this by changing my monitor resolution when using aPriori). Also, more of a knit-picky complaint, but I have a difficult time thinking in seconds, so having things like cycle time displayed in seconds requires me to do some mental math to conceptualize the amount of time spent on each operation. Both of these cons are greatly outweighed by the value provided by the software and overall really aren't problems at all.