Aptean Industrial Manufacturing ERP Made2Manage Edition

About Aptean Industrial Manufacturing ERP Made2Manage Edition

Aptean Industrial Manufacturing ERP Made2Manage Edition Pricing

Free trial:

Not Available

Free version:

Not Available

Other Top Recommended Manufacturing Software

Most Helpful Reviews for Aptean Industrial Manufacturing ERP Made2Manage Edition

1 - 5 of 30 Reviews

Terie

Used free trial

OVERALL RATING:

4

EASE OF USE

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed August 2013

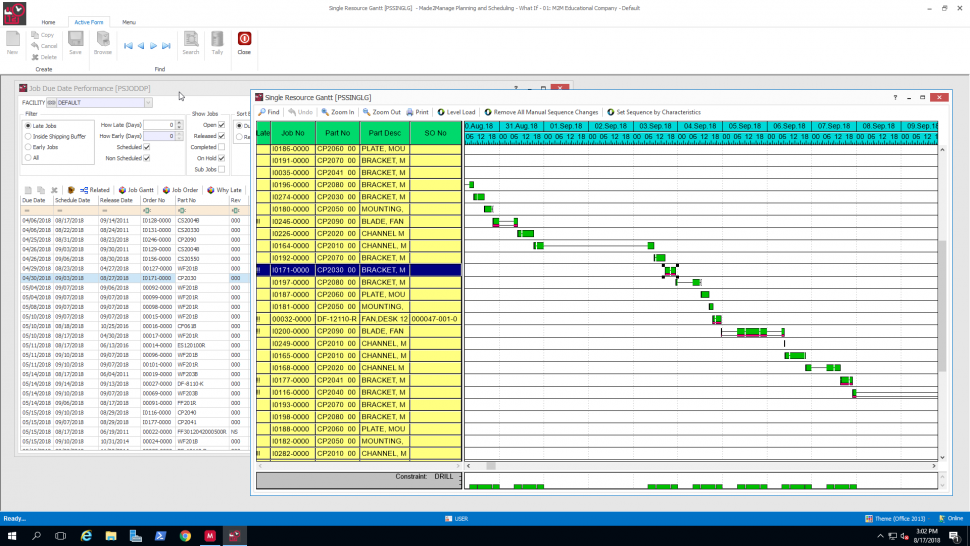

White's Electronics, Inc. manufactures metal detectors for the sport and hobby market, however, we are looking at new markets for diversification. We are a make to stock company. When we purchased M2M in 2007, we were looking for a product where we wouldn't have to modify every screen and report to get the information the way we needed. We didn't want to have to buy a lot of add on products to get the information. M2M seemed to meet our requirements. We have modified some reports and screens and M2M provides tools to do this. Our users like the fact that they can export almost any report to excel and use it they way they want. The online courses are very helpful and the users refer to them often. They users were able to adapt to the features and use of M2M fairly quickly. We have 20 licenses, however, we have 40 users. We use the time out feature to keep logins available. We use Advanced Scheduling to keep our inventory to a minimum. We are currently working on a test machine to upgrade to 7.01. Our live company is using 6.02 SP5 HP4.

Daniel

Used free trial

OVERALL RATING:

4

EASE OF USE

4

CUSTOMER SUPPORT

3

FUNCTIONALITY

5

Reviewed August 2013

Norscan Instruments Ltd. is an Electronics Engineering and Manufacturing company with about 30 employees. We have a relatively large number of products, most of which are small volume. We had to support our existing products for at least 10 years (or more), and many of the products were customized for each customer. Most of our products have circuit boards, which can have hundreds to thousands of individual components, along with multiple sub-assemblies - which make Bills Of Materials (BOMs) very complex. Back in 1997, we were looking for an ERP system that could tie our accounting, purchasing, product bills of materials, and labor reporting all together. At the time, all of these existed in their own software, or databases and spreadsheets. It was imperative that the system be able to handle multiple levels of BOMs and Routings. After looking at a few systems, it became apparent that there was a significant effort required just to evaluate these systems to measure performance against a set of requirements. At the time, we did not have any resources available to do this, and there was a local VAR that sold, integrated, and supported Made2Manage (M2M) locally (which was M2M's model then). The pricing fit our budget and we went ahead and purchased the system in 1997 with a target of going live in the start of 1998. The version at that time was based of Visual Foxpro. The implementation was a bit bumpy at first. Our system was the first for the VAR, and actually we were one of the first companies in Canada to use M2M, and there were a number of things that were not Canadian-ized. M2M was very quick to make these changes in the software. Our VAR designed many custom reports for us (wrote full code) that we later found out wasn't really necessary, as the "canned" reports in M2M can be easily tweaked to suit most companies needs. This is an important factor for future upgrades as custom reports may not function if there are database changes with the upgrades. The entire staff was trained, and like any new system, there was some hesitation, duplication of work, and many errors. This is why we ran M2M parallel with our existing systems for a few months before going live. Something that I don't think would be acceptable in a larger organization. We persisted, and were completely ready when it was time to go live. In general, M2M is fairly easy to use. The GUI is straight forward, and has had major improvements over the 15+ years we have been using it. The majority (if not all) improvements have come straight from the users themselves, and as more and more customers purchased M2M, the feedback just became better. When there are issues, M2M support team is there to help. Unfortunately, the help usually takes longer than the user wants, as usually something will go wrong and you need it fixed immediately. Most problems usually are resolved within 24 hours. As a user since 1998, we have build up a lot of in-house expertise, so to be fair to M2M, when we call for support, it's usually due to a very complex issue - usually requiring a second level or higher support person. We have purchased additional add-on modules (advanced reporter, production scheduler & shop floor manager). For accounting/finance, I don't think you can do without the Advanced Reporter. It makes writing custom financial reports a breeze. Our MFG personnel really like the addition of the Shop Floor Manager. It allows for each individual or work center know what they need to work on that day, what the status of materials are for the job, and an easy way to enter in their labor. Over the years, we have continually changed processes in order to obtain better quality and margins, and M2M has been an important tool in order to gain the type of visibility needed for both Quality and continuous improvement. Today, we still don't use all the features in M2M, but we are always looking at those features each year to determine whether it makes sense to implement into our business or not. Over the years, there have been quite a number of people who have gained expert knowledge about M2M (outside of the M2M staff), and as such there is usually a pretty good knowledge base in the forums. I would certainly recommend M2M to anyone in our line of business.

Andrea

Electrical/Electronic Manufacturing, 11-50 employees

Used daily for more than 2 years

OVERALL RATING:

2

EASE OF USE

3

VALUE FOR MONEY

2

CUSTOMER SUPPORT

1

FUNCTIONALITY

2

Reviewed October 2018

Made to Manage more like Made to Damage

In 2006 the company I worked for was sold M2M as a ERP system that would make our business paperless (mostly) We killed more trees after installing it. The notifiers were less than helpful and most users stopped looking at them because the information was useless. When it came to digesting information in the system to make sense of what are actual inventory #'s were or job statuses we had to have a programmer write a script that pulled the info from M2M and redesigned it into something legible using Excel. He finally wrote the script to include BOM (parent/children) where used, pick tickets for each machine build or job running through our machine shop as well as parts orders. The features we needed were just not there. So they promised it would fix it in the next update, then the next one and next until we on 6.5 which crashed our network (some type of bug) The field service module which was purchased as an addition did also not work as promised. All BOM would have to be loaded in order to create a service case, then create a sales order or work order from there.

PROSM2M is very easy to learn and easy to navigate. Can be customized but for a price. If there are other users in your area M2M offers user group meetings that can be very informational. They also have M2M university which is a series of in depth how to's on the various functions within the system. Can set each user to only have access to things pertaining to their job function within the company.

CONSNot a paperless system!! Reporting is awful. Newest version allows for too many mistakes. Areas that should not be able to be edited are still open once saved; including the inventory screen! After latest update UPS Worldship interface no longer worked. Sure they offer customization however unless they have an overwhelming demand for the feature your company may need to do business the charges to write the script and update your version are high. When sending a service trouble shooting ticket do not expect an answer right away. It typically takes there service team several days to respond and most of the time the answer is we need to look further into it.

Mary

Used free trial

OVERALL RATING:

4

EASE OF USE

4

CUSTOMER SUPPORT

3

FUNCTIONALITY

4

Reviewed August 2013

As a job shop providing - primarily - custom products to customer design specifications, we have small production runs and little finished inventory. But we have lots of costs! Our previous software was great for accounting but did little to address collection, assimilation or analysis of production data. We examined ERP software and decided M2M would answer those questions and, as a result, we'd be better able to move our business forward. We recently (Feb/Mar 2013) upgraded to M2M 7.01 (from version 5.6). Thankfully there are two versions - classic, which looks and acts like our older version; and .NET, with a sleeker appearance and more direct functionality. Most of our employees are very comfortable with the Classic version. The more adventurous of the staff use the .NET as often as possible, reverting to the Classic only when we get "lost" - or, on rare occasion, when there's a hole in .NET (and, yes, there are still a few). Management is enduring extensive training on 7.0 modules. Our philosophy is that now is the time to make corrections and adjustments to the way we do things. This version is quite powerful and more user-friendly, but it takes some getting used to. And we want to do it "right", or as "right" as possible. The online recorded courses have been instrumental in launching discussion and decisions. As a result, we are comfortable moving our employees into the more modern system presented by this version and out of their comfort zone(s). M2M personnel have been helpful, for the most part. We did not use a reseller (our first - and last - experience with a M2M reseller was less than pleasant or productive) but used M2M staff for the upgrade and install. Getting to the upgrade/install point was often challenging (like pulling teeth to get anyone to return calls) but it's been good ever since. We still have additional training that needs to be done, but before we'll bring that in, we want to be fully - as much as possible - conversant with the software so we can ask intelligent and meaningful questions and get the most of those limited training hours. Some improvements we like in .NET would be ease of changing data/data tables, better windows and customizable screens, having "favorites" very accessible, access to reports for minor customizations, planning and scheduling/CRM modules (although we don't really know how to use them yet), and quick and easy exports to Excel (some of us are spreadsheet geeks). There's undoubtedly some more that escapes me right now. Would we purchase M2M again? Well, we've invested quite a lot in this software, as we've been using it since 2001. We've learned that no system is perfect and it doesn't hurt that my staff has threatened me with bodily harm if I change at this point! We're excited with the improvements the 7.0 offers. There's more that we'd like to see upgraded but it's getting there, and we've learned (and will continue to learn) how to manipulate M2M to be the best it can be!

Brian

Plastics, 11-50 employees

Used daily for more than 2 years

OVERALL RATING:

4

EASE OF USE

4

VALUE FOR MONEY

4

CUSTOMER SUPPORT

4

FUNCTIONALITY

4

Reviewed October 2019

Made2Manage

It has been a very stable system for us, especially after upgrading to 7.50, then 7.51. We are running it on a Hyper-V 2012 R2 server which is shared by the 2014 MS-SQL database. The physical machine is running all SSD's and speed has not been an issue. We run it on Windows 7 and 10. Overall, we are able to effectively run the company with M2M and has become very routine for us. We have been using M2M since 2000 and version 5.5.

PROSThe software has evolved a lot in the past few years. Many of the reviews are based on old versions of the software, and there was a lot of room for improvement. The latest version (7.51) is a huge improvement on previous versions. The interface is much cleaner and the logic a lot better. The new ability (7.50) for any user to easily export data from a browse window (almost every screen) and from any report is a big deal. The overall look is more Windows-like, but retains the same general forms as before; great if you are upgrading. When it looks like M2M improperly calculates something, it always turns out to be something a user did, allowing me to trust the system.

CONSSometimes it is hard to figure out what a field on a form is for based on the description alone, leaving it up to each user to decide how to use it. For the most part, this only comes into play for features we don't use.