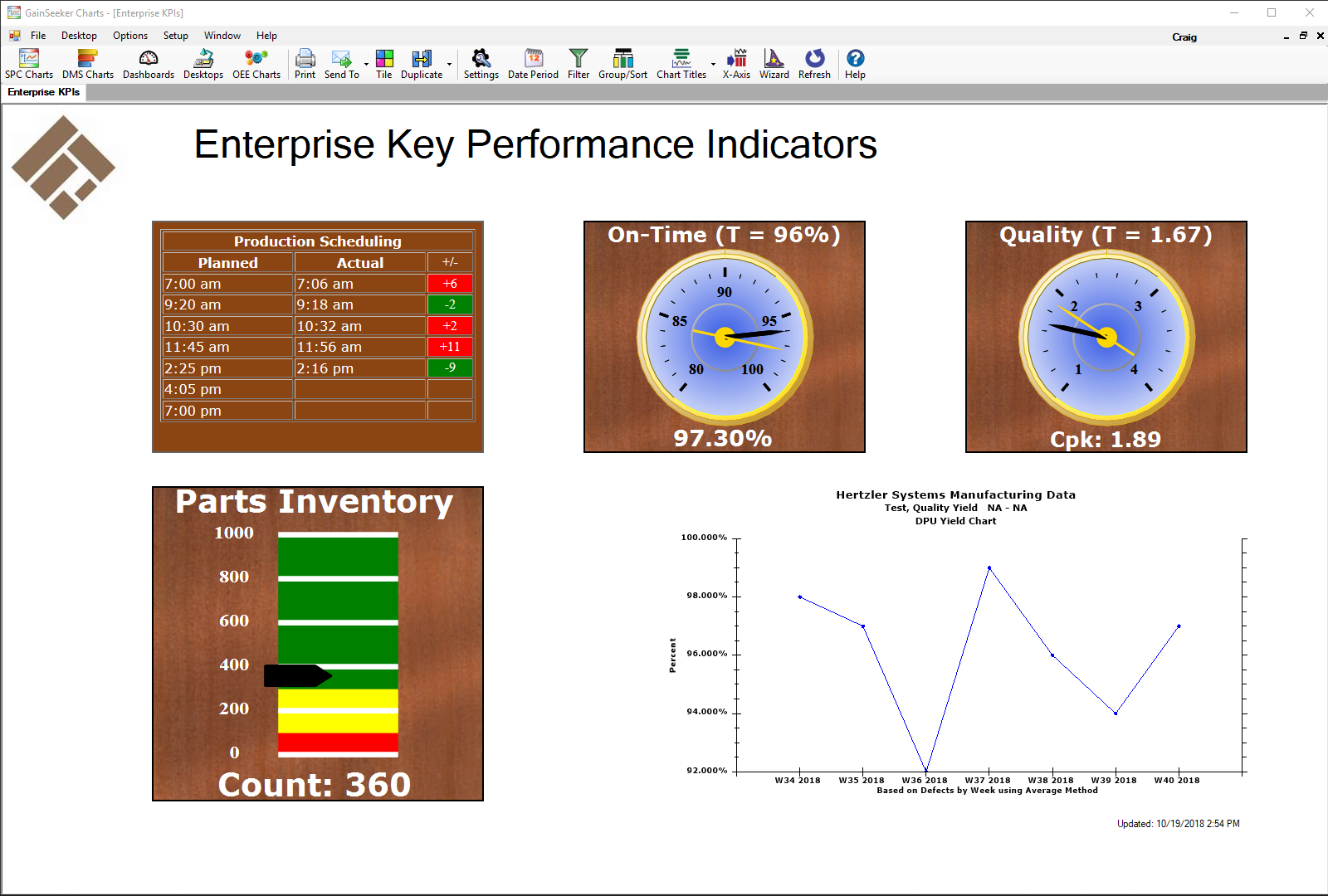

GainSeeker Suite

About GainSeeker Suite

GainSeeker Suite Pricing

Pricing is available on a one-time license basis based on the number of plant deployments, number of lines, and number of seats as follows: • Scenario A: $10000 for single deployment, one number of line, and two seats • Scenario B: $20000 for multiple deployment, three number of lines, and six seats • Scenario C: $80000 for single deployment, one number of line, and twenty five seats • Scenario D: $500000 for multiple deployment, multiple number of lines, and 150+ seats

Starting price:

$2,195.00 one time

Free trial:

Not Available

Free version:

Not Available

Other Top Recommended Manufacturing Software

Most Helpful Reviews for GainSeeker Suite

1 - 5 of 44 Reviews

Anonymous

501-1,000 employees

Used daily for more than 2 years

OVERALL RATING:

5

EASE OF USE

4

VALUE FOR MONEY

4

CUSTOMER SUPPORT

4

FUNCTIONALITY

5

Reviewed August 2018

GainSeeker

We use the system for not only what is was developed by it designers to do, but many other areas. We use it to be a tool for data collection info from may areas of our process. It pulls them all together and analyses the data and gives us a statistical representation of all that is happening.

PROSWe were looking at multiple companies for our new program. GainSeeker gave us the most options and allowed us to customize the system to our needs. The other systems wanted us to fit our needs into their predetermined mold.

CONSAt times it was difficult to get across to our service rep what we were looking to do (when it came to customization) but in the end when we detailed it out (defined what we really wanted and needed) they were able to give us exactly what we wanted.

Vendor Response

Thank you for your review and feedback on the integration process. We love the challenges customers present us with and teaming with them to come up with solutions that meet their needs.

Replied August 2018

Trues

Food Production, 201-500 employees

Used daily for more than 2 years

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed March 2021

Customizable SPC Powerhouse that drives tactical and strategic improvement

Our experience has been a real partnership. We have worked together on multiple implementation projects across multiple facilities and they have a great grasp of what we do and how we work. They truly partner with us when implementing something new to ensure seamless implementation, training, and deployment. The speed at which we have launched new projects has been a huge asset and is in no small part to their philosophy of partnership.

PROSGS is completely customizable. It's only limits are what you and your teams limitations on creativity are. It has an easy to use spc suite of tools including OEE, control charts, process capability ratios and indexes, and many others that can be shown for easy interpretation. We use it for all quality metrics, labor assignments, downtime, process improvement logs, and leader standard work. It's versatility, ease of use to drill down, and customizable dashboards are what really set it apart

CONSNothing I like least. Looking for the Hertzler team to develop some more data entry tools such as drag and drop. They've been very responsive to requests for improvements/ enhancements for future versions.

Reason for choosing GainSeeker Suite

Its ability to customize, drill down and show visual representations of data to multiple audiences and drive action.

Vendor Response

Thank you Trues for taking the time to review GainSeeker. We work everyday to maintain the high marks you gave us and look forward to working with your company on future projects.

Replied March 2021

Molly

Plastics, 1,001-5,000 employees

Used daily for less than 6 months

OVERALL RATING:

3

EASE OF USE

5

VALUE FOR MONEY

5

CUSTOMER SUPPORT

4

FUNCTIONALITY

3

Reviewed January 2017

Super glitchy

We have had several error messages that popped up shortly after implementation, which frustrated several employees. The dashboard data only takes screengrabs, which makes it difficult to send to the team when we have more information than is on the first part of the box

PROSVery easy to use on front line

CONSGlitchy

Vendor Response

We appreciate your feedback on the error messages. We'll be in touch to learn more.

Replied January 2017

Dustin

Defense & Space, 51-200 employees

Used daily for more than 2 years

OVERALL RATING:

4

EASE OF USE

4

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed January 2017

Great bang for your buck and awesome customer service

My company has had this software in operation for a little over 2 years now and we have expanded its use well beyond our original scope. We have scripts setup to capture PLC data for our various machines and record the defects and good parts being produced as well as an hourly sampling of the machines dimensional measurements. Recently we expanded the use of GS into our chemical lab where our engineers and lab techs are recording their various findings for materials. This allows the engineers for the production lines to have immediate access as well as graph changes over time. Another expansion beyond standard SPC has been our test lab recording first articles and lot acceptance testing. This has given us the ability to do easy and direct comparisons between production lots and compare material being used to determine variances. Our defect monitoring setup has allowed us to quickly see where problems are as well as cost analysis to put that "price of quality" on those defects. Some of our equipment is currently in the process of several upgrades that are partly due to the engineering groups using this data to justify the capital expense. The Python scripting has been great for collecting as well as organizing data. One noticeable area is aerospace requirement AS9102 first article paperwork.

PROSCustomizable to a wide range of applications

CONSDoes not work with USB devices well. To the point of using them becomes more of a chore than useful. Example, we have a 4inch digital indicator that uses a USB output cable in order to transmit data rather than a serial RS232 port which is what we use for our resistance meters etc.. Because the software is COM based rather than looking for the plugins and drivers based on the name of the device, every time the computer is rebooted it is a toss of the dice as to whether or not Windows will assign it the same COM port number. There is software out there that can assist with this but in todays environment more and more devices talk using USB 2.0 & 3.0 rather than RS232. That being said most of our devices have both options or use a cable along the lines of a Mitutoyo 10 pin.

Vendor Response

Thanks for insight around the importance of developing your internal capacity to expand deployment. GainSeeker is a powerful platform, and you've put your finger on the key: extending functionality through Python. We also appreciate your reflections on USB devices. Congrats on a great deployment.

Replied January 2017

Gary

Verified reviewer

Food Production, 501-1,000 employees

Used daily for more than 2 years

OVERALL RATING:

4

EASE OF USE

3

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed August 2018

Overall happy with Gainseek as it allows our plant to run efficiently

Overall we are happy with GainSeeker. It allows us to keep a database of all of our standard checks, set the limits of those checks, either positive or negative, and react quickly using our dashboards to problems in realtime. The ability to tap into the backend DB and display stats to the works is a huge help as well. Looking forward to the new features in new releases.

PROSThe software itself is pretty easy to use once setup. It guides you through checks against standards on our manufacturing lines. Users are easily able to do their standard checks with limited interaction from managers. We run an RDP session on a thin client which cuts down the price for machines on the floor, and overall hardware. We use the backend database to show stats to the plant workers to help them be more efficient and more informed of what they are doing line to line and product to product.

CONSSetup can be a little confusing and not all options are available right out of the box. Once we dialed in it was good. Tracking down an issue with a standard check can be a little cumbersome if you don't know what your looking for. Normally rely on tech support for these issues.

Vendor Response

Thank you for the review and using GainSeeker. We greatly appreciate user feedback and the window you provided into how your facility is using the software. As you noted, we have exciting new features slated for future releases in the near future.

Replied August 2018