WATS

About WATS

WATS Pricing

The product offers pricing plans based on two components- 1. Based on selected features, available in four alternatives - WATS Basic - Free forever - WATS Analytics - from €249 per month for 30 users - WATS Enterprise - from €489 per month for unlimited users - WATS On-Premise 2. Volume of data processed Add pre-paid cost-optimized data packages to your subscription to process and analyze all your test and repair data, regardless of volumes.

Starting price:

€267.00 per year

Free trial:

Available

Free version:

Available

Other Top Recommended Manufacturing Software

Most Helpful Reviews for WATS

1 - 5 of 11 Reviews

Chris

Verified reviewer

Computer Software, 51-200 employees

Used daily for more than 2 years

OVERALL RATING:

5

EASE OF USE

4

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed September 2018

Understand your product and its performance

SkyWATS allowed us to perform R&R comparisons of test stations in a fast and efficient manner and immediately highlighted an issue with a slight mismatch in performance which we were able to rectify (and verify the fix) with minimal downtime. I've used this product for over 10 years because I trust it and the team behind it.

PROSProvides an almost "codeless" solution for those looking to quickly store test data from TestStand / LabVIEW. The data that is stored is then able to be reviewed and analyzed quickly allowing us to respond to product yield or performance issues in a proactive manner. Critical for any complex high volume test solution.

CONSInability to define (or add) custom queries or reports.

Bryan

Electrical/Electronic Manufacturing, 1,001-5,000 employees

Used daily for less than 2 years

OVERALL RATING:

5

EASE OF USE

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed June 2020

Data, data, data

Overall, using WATS is a great experience. We are able to look at specific data and understand how our production is affected, good or bad. We also use WATS to collect test reports on individual PCB's as well as completed products, this gives us great transparency over our production floor.

PROSSince switching to WATS, the data collection and collation has helped our production teams to truly understand some of the issues we were having. This helped our teams to focus on changes that helped with our assembly and test areas.

CONSIntegrating with some of the other software platforms we already had in place was difficult at first and was a bit much having multiple resources giving us, effectively, the same information. However, once that was streamlined, it has become a vital tool.

Alexis

Verified reviewer

Medical Devices, 201-500 employees

Used daily for less than 2 years

OVERALL RATING:

4

EASE OF USE

4

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed August 2018

Great tool for SPC !

We are using Skywats for SPC and analyse test yield, quantity tested per day/week and to improve our process, test benches and test softwares. This tool is very powerfull and give us quickly and easily, a lot of precious informations we took a lot of time to find before.

PROSEasy to use and for looking information. Great for SPC analysis and be proactive for production support. Give us key parameters (yield, top 10 failures...) to improve our test bench and test software.

CONSNeed training and practice to understand and find informations we are looking for.

Xiwen

Verified reviewer

Renewables & Environment, 11-50 employees

Used daily for more than 2 years

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed July 2018

working as Manufacturing test engineer for over 12 years

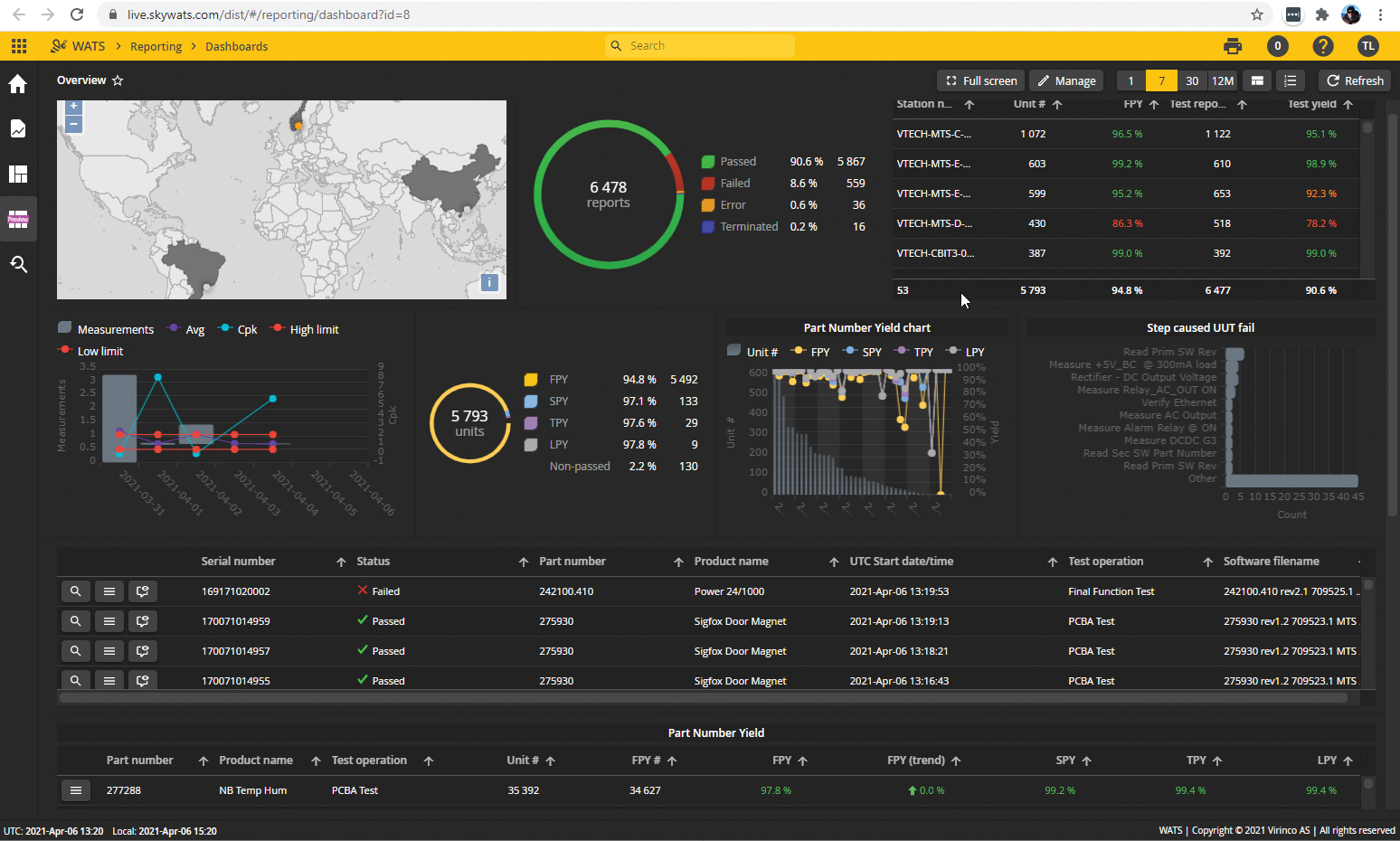

be able to have the overview of the weekly/daily first pass yield, make it easier to target the highest failing test step in the manufacturing test.

PROSvery easy to bring the statistics for the period that the user is interested in. it gives graphic view for the measurements in the manufacturing , highlights the highest failing steps with failing rate.

CONSit needed to preload the sequence model in TestStand back when I was using it. If it can be a hot plug app that can be merge in after the test development, it'll be great!

Jyri

Verified reviewer

Electrical/Electronic Manufacturing, 5,001-10,000 employees

Used daily for less than 2 years

OVERALL RATING:

4

EASE OF USE

3

VALUE FOR MONEY

5

FUNCTIONALITY

4

Reviewed August 2018

My Review

So far the skyWATS have reduced our problem solving processs' lead time signifcantly and the available data with complete test history immediately shows the proble as it is now and how it is comparable to previous tests

PROSThe level of automation to the test data management, easiness of cloud based service, no need to maintain tools

CONSSometimes it feels that you have almost too much alternative approaches to get needed results so it's bit easy to lost in the GUI.