12 CMMS Best Practices to Turn Your Maintenance Team Into Power Users

You just adopted a maintenance management system? Congratulations! Your company will be reaping the benefits of maintenance automation for many years.

But first! You must reinforce 12 best practices to make sure the system actually delivers value. Messy, inaccurate data and slower completion rates are common symptoms among untrained maintenance teams.

Arming users with the most important CMMS good habits from the beginning is the best way to maximize maintenance automation benefits long into the future. I reached out to a few CMMS providers for best practices that help new teams reap the benefits from maintenance software and turn your technicians into power users.

1. Get Management Buy-In and Support

Without the backing of your management, your maintenance team won’t take full advantage of the CMMS.

A company-wide commitment shows all employees that the software is a critical piece of the maintenance strategy and should be used correctly to achieve the desired benefits, says Steve Wigton from MAPCON.

“Sometimes managers show support by attending training classes or asking questions, even if they will not be using the system themselves,” said Wigton.

Action: Gather maintenance leaders with the rest of management and develop a program that conveys the commitment to using the new system. For example, management can demonstrate how CMMS benefits impact overall business goals and celebrate ongoing wins as users become familiar with the software.

2. Establish a Long-Term Relationship With the Vendor

A CMMS purchase should also include ongoing communication with the vendor, and many have specialized teams to make sure clients are successfully leveraging their technology.

Daniel Golub from Hippo CMMS recommends being proactive about keeping communication open so you can stay on top of details about upcoming software updates, new features, webinars or other check-ins.

“If you are on a subscription-based license contract, know that it is also in the best interest of your provider to satisfy your requirements,” Golub says. “Don’t assume that they will always act accordingly. Be proactive and make them earn your company’s dollars—it’s a win-win for both groups.”

Action: Inquire about the vendor-client relationship, including their phone and online support resources, communication channels and methods for addressing common problems. Ask for real examples the vendor has handled in the past. These questions can help you decide how that relationship will work:

What exactly do your support services include?

How do you keep your team up-to-date on new maintenance technologies?

How long after deployment will your team be directly involved with us?

3. Customize the System for Ease of Use

It’ll be tough getting your team to use the CMMS if it’s a confusing experience. Plus, there are several features in the system, like reporting or supplier management functionality, that technicians completing jobs in the field don’t need to use. Wigton recommends a system with a level of customization to make it as easy-to-use as possible.

“Finding a user-friendly system that allows some adjustments, such as easily personalized windows or labels, can help the user feel more comfortable with understanding and using their system,” Wigton says.

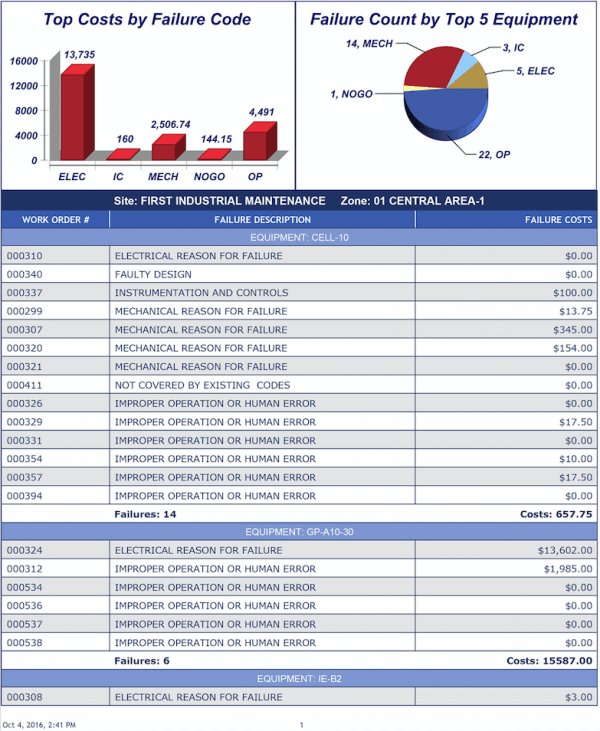

A customizable report in MAPCON keeps focus on important maintenance data (Source)

Changing the culture of a maintenance department to effectively use a new CMMS is already a challenge. Customizing the system so it’s simple and helps technicians perform better and faster will increase usability.

Action: Work with the CMMS vendor to customize a role-based user interface. For example, limit access for technicians performing work in the field only to features needed to complete the task, but give managers access to more advanced functionality. This streamlines the experience for all users and maximizes the time-saving benefits of automation.

4. Integrate Mobile Capabilities to Save Time

Your technicians are already carrying around a valuable tool all day: their own mobile device. Using a CMMS on smartphones can help save significant time usually spent traveling between the job site and the office, and give workers access to the system anywhere they go.

“Find out from your provider what types of mobile capabilities your system has and start using them,” says Brian McDonald from Dude Solutions, which offers Asset Essentials and other maintenance solutions.

“Whether it’s a way for field workers to log their time or track work without having to come back to a desktop or the proof you need to request tablets or smartphones for your team, it can greatly improve your efficiencies.”

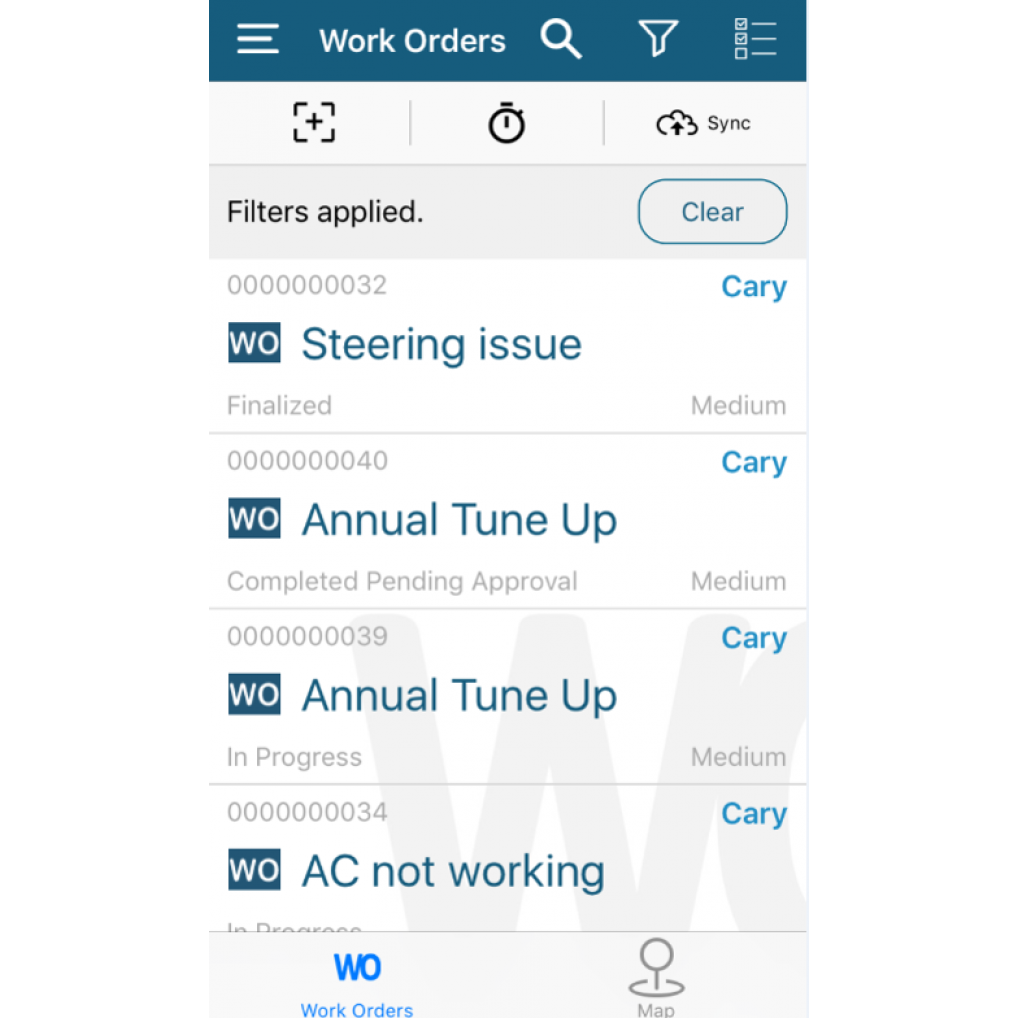

You can view a list of work orders in the Asset Essentials mobile app (Source)

Workers can use their smartphone to take photos of damage and share it with other CMMS users, pull up asset details quickly or sign electronic documents at the job site. This is a common feature in modern maintenance systems that can deliver big wins immediately.

Action: Gather your team to determine all the potential use cases for smartphones that could benefit your team, from simpler user interfaces to the ability to scan barcodes in the field. Share these examples with the vendor to find solutions you can implement.

5. Take Advantage of the Latest Technologies

Technologies such as AI, machine learning and data analytics unlock the value of all the information your team collects every day, helping you make more data-driven decisions, says David Markowitz from ServiceChannel.

“By analyzing prior decisions and past data with prescriptive analytics, machine learning tools can recommend how best to respond to contractor proposals and invoices, and provide needed information for more accurate asset repair/replace decisions,” he says.

IoT technology significantly improves your view of asset health in real time

Internet of things (IoT) devices also enable communication among all the assets you maintain, giving you a way to remotely monitor and control machinery and stream real-time data into the CMMS. Vendors offer these technologies at costs affordable for nearly any sized business.

Action: Inquire about integrations of new technologies—like IoT or AI—that the vendor has worked on in the past. Also, ask for specific use cases for each kind of technology and the benefits clients can expect to see.

6. Tag All Assets for Stronger Tracking and Inventory Management

Decision-making around repair or replace and maintenance scheduling is a critical responsibility and a large expense, Markowitz says. Tracking your assets allows you to see where all machines are in order to optimize reliability and value.

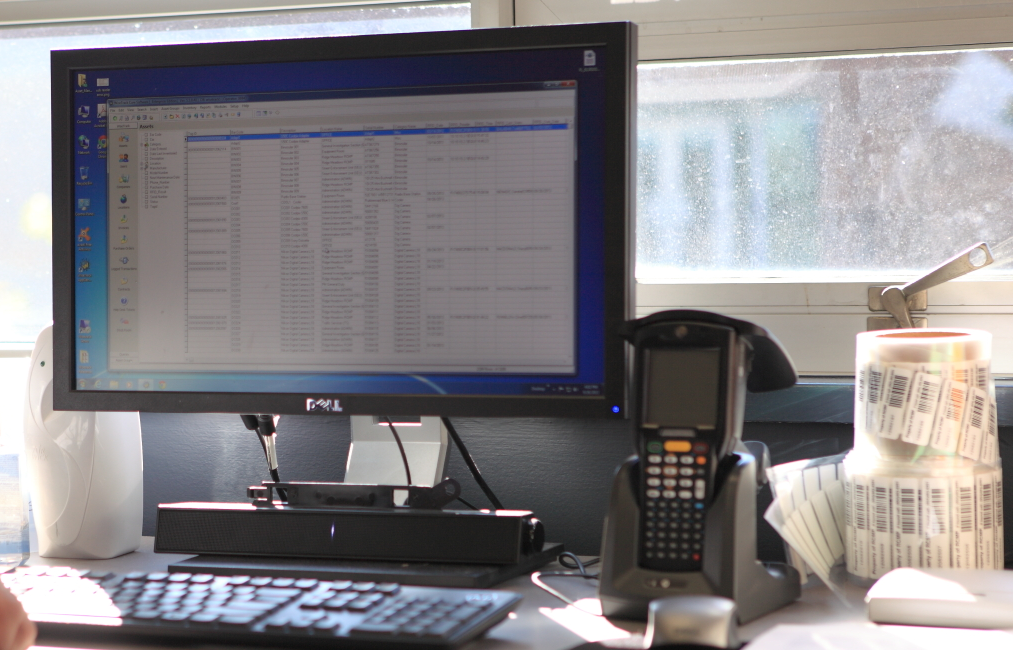

“With integrated asset tagging functionality, you may accurately track and manage your assets across your locations, by scanning asset tags using QR barcodes or NFC (e.g., RFID) technology,” he says.

A common set of asset tracking tools: a handheld scanner and a belt of RFID tags (Source)

Using a smartphone to scan a barcode, QR code or RFID tag is one of the simplest methods of retrieving and editing asset details while mobile. This type of tracking also helps prevent losses and spot potential failures more quickly.

Action: After profiles for your most critical machines are entered into the CMMS database, identify the top 10-15 percent of assets that are critical to smooth operations. It’s smart to add barcodes or tags to these assets first.

7. Standardize Data Entry Requirements

A CMMS serves as, among other things, a repository for valuable data about repair histories, asset operating conditions and more. But if users aren’t on the same page about how to enter data, it’s difficult to extract meaningful information.

In a recent survey, Gartner found that poor data quality costs companies an average of $15 million a year, and will become more expensive as data volume grows. (Full content is available to Gartner clients.) CMMS vendors know this, Golub says, and have experience establishing a standard for maintenance data.

“It works best if everyone in the organization speaks the same language and is on the same page,” he says.

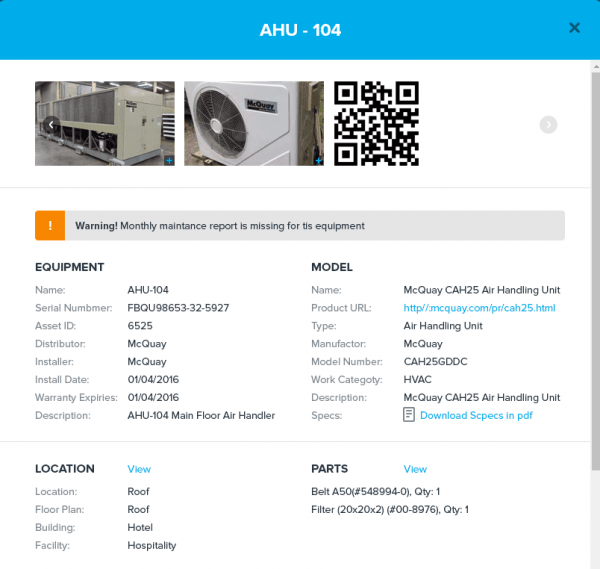

An asset profile in Hippo CMMS includes a standardized Asset ID code (Source)

Action: Work with your vendor to develop or find a standard that fits with the system’s structure and is simple enough for all users to understand. Then, hold an initial training meeting to share the logic behind the standard. Continue holding training sessions until all users understand and can identify codes.

8. Manage the Compliance of Your Service Providers

Depending on your type of maintenance, you may have multiple contractors and service providers performing work at your location. These workers are important to your operations, but must meet the requirements of your site as well as local or state regulations.

“Each time a technician comes on site, a company relies on its provider to have the proper levels and amounts of insurance, required certifications, licenses etc. in place,” Markowitz says. “If not, a company faces unknown operational and financial risks should something happen.”

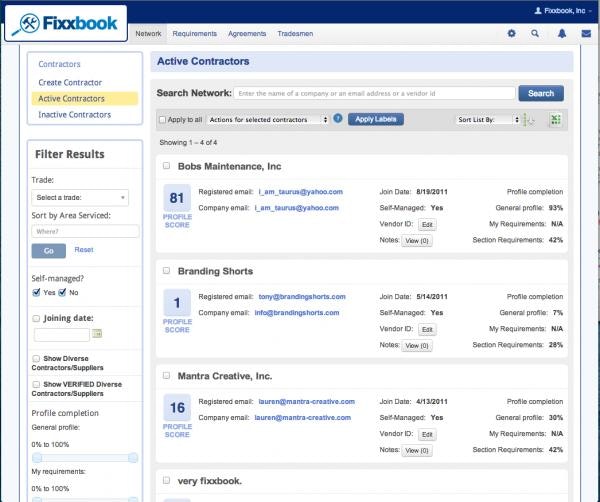

Fixxbook by ServiceChannel maintains records of compliance and assigns a percentage score (Source)

Compliance management features can be integrated into a CMMS to show the certifications and compliance of each contractor, he says, and helps companies remove noncompliant workers to avoid operational, financial or legal risks.

Action: Import your list of contractors into the compliance system or CMMS, and use it as a chance to update certifications for each worker. As work is completed, you can collect records for repairs that serve as an audit trail during compliance reviews.

9. Adopt Ongoing Software Training Practices

Software providers want your team to take full advantage of the system, so training is not only essential for new users or when upgrades are available. It should be done on an ongoing basis, Wigton says.

Even if you decided against training when you first implemented the CMMS, the vendor can offer continuing education with online materials and/or in-person courses to keep users’ skills sharp. This has the added bonus of encouraging workers to use the system correctly, she explains.

“Attending CMMS training classes somewhat regularly not only gives users the opportunity to discover new ways of doing things, but it also recommits them to using their CMMS,” he says.

Action: Speak with your vendor about their training resources, and determine the level of training needed to make sure technicians accurately enter data. Then, consider scheduling annual sessions to help all users brush up on their skills and learn about new functionality.

10. Have More Than One CMMS ‘Owner’

After implementing a new maintenance system, a company should assign at least two people to serve as a source of CMMS knowledge for all the users. Golub says it’s critical to also make sure that this information is passed along as employees come and go.

“We have seen CMMS systems go unused and money wasted because the initial champion left the company and did not pass on his or her knowledge,” Golub says. “Having more than one person who knows the ins and outs and is connected with the CMMS provider’s support team is important.”

These “CMMS ambassadors” can be liaisons who answer questions and help run workshops to make sure users have the skills they need to make sure the system delivers the value it’s meant to.

Action: Choose two or more software users who are approachable and enthusiastic about using the CMMS properly to be system champions and notify all users. Assign them recurring meetings where they can gather details about updates and best practices to share with the team as needed.

11. Empower Your Power Users

Beyond making them CMMS ambassadors, McDonald also suggests giving these power users access to new functionality or processes to test them for the rest of the team.

When the power users show the rest of the team that a new feature can make their jobs easier or result in significant boosts to efficiency, they’re more likely to use it.

“Use any success stories of time saved or risks avoided and share them with the rest of your team to highlight their work,” he says. “You can even create competitions around hours worked, money saved or documenting all of that within your CMMS to encourage camaraderie and further adoption.”

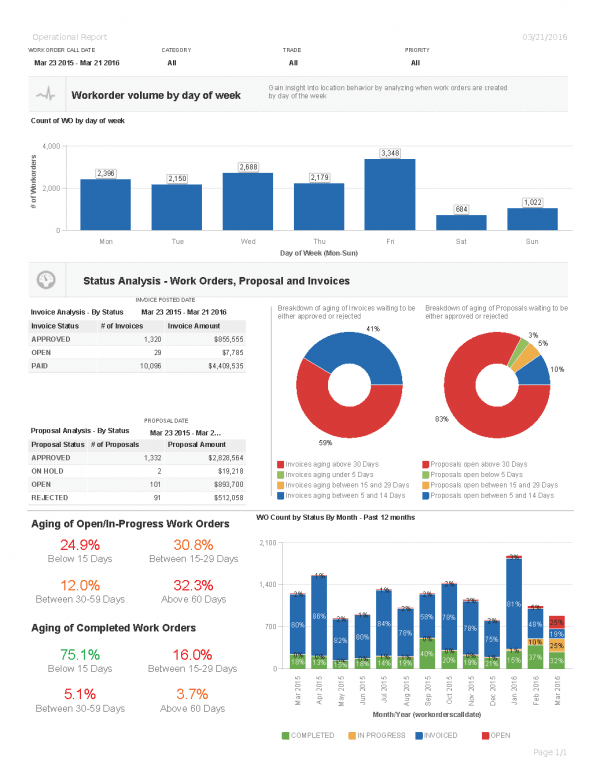

Power users can share improvements shown in reports, like this one from ServiceChannel (Source)

Action: Schedule meetings with your CMMS ambassadors to try new features before the rest of the team, and communicate the biggest benefits from individual users and the company as a whole to encourage continued use.

12. Dive Into Your Reporting

Once you’ve had some time to use the system and collect data, leverage this data for valuable insights on more than just maintenance scheduling and asset health. McDonald says reporting functionality can also help you budget and forecast future needs as well.

“When you can harness the power of your daily work, asset and inventory data, then you can use that to prove your need for more resources—whether it’s technology, hiring, asset replacements etc.,” he says.

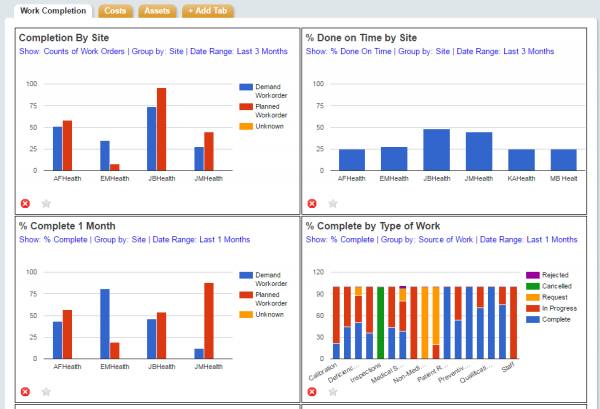

A view of reports in TheWorkxHub__, a health care-focused system from Dude Solutions (Source)

Modern CMMS solutions offer reporting in the form of easy-to-read bar graphs, charts, PowerPoint templates and more. You can directly share these reports with your management or administration and use them to make quick decisions that improve your processes on a daily basis.

Action: Maintenance managers should get specialized training to generate reports that help them spot trends in repair histories, types of work or completion rates. Send a recurring set of important reports to convey the overall health of the maintenance department to stakeholders.

I’m Ready to Get the Most From My CMMS!

Continue to reinforce these 12 best practices so your CMMS investment delivers all the benefits you expect. We have many other resources to help you maintain that success.

We analyzed hundreds of buyers who call Software Advice for a CMMS to find out the functionality they need as they grow. Review our list to make sure you have the maintenance features for your size.

A change in your culture is necessary to re-establish focus on strong maintenance management practices. Use these four tips to improve your team’s use of the new CMMS.

With a new maintenance system in place, you’re set up to take advantage of smart maintenance technology that ties all your assets and systems together. Three steps can get you there.

_

Note: The information contained in this article has been obtained from sources believed to be reliable. The applications selected are examples to show a feature in context, and are not intended as endorsements or recommendations.

_