3 Smart Maintenance Solutions to Get More from Asset Data

The term “smart” is used to describe a wide variety of technologies—cars, watches, and even light bulbs.

But it’s not always easy to know which solutions you need as a maintenance professional. Which sensors or software actually result in practical facility improvements?

Using Gartner’s Internet of Things (IoT) and smart building research, we narrowed down the technologies to three that deliver on the smart maintenance promise.

1. Sensors: Gather valuable building data with condition monitoring

As a facility manager, you have a wealth of useful data produced by your building every day. When collected over weeks, months and years, this historical data is the most powerful tool available.

If reactive maintenance or predictive maintenance is your current strategy for handling work requests, sensor data can be the ticket to a more effective condition-based maintenance strategy.

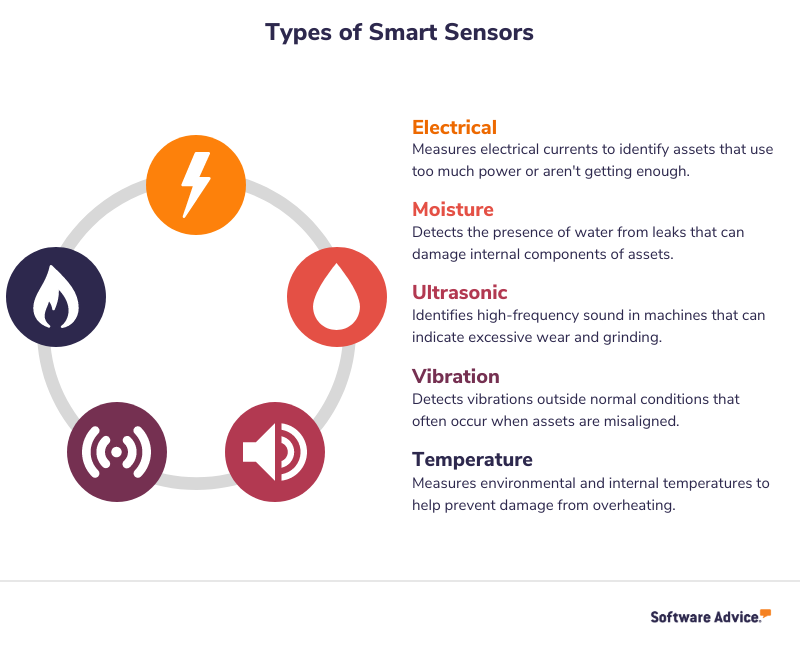

A wide variety of sensors are available on the market to deliver insightful data for whatever asset you want to monitor.

Sensor capabilities are improving, and the cost of sensors is dropping quickly. Currently, a water presence sensor is only around $100 to $200.

WHERE TO START: Identify your most critical assets, those that have the most direct impact on your building’s occupants being safe and comfortable. Monitor those assets with sensor technology first for quick wins.

2. Big data: Monitor key KPIs with sensor data

Before any investment, you should determine exactly why it’s needed. These kinds of questions define the goals and identify the specific problems you want to tackle with technology.

Ask yourself questions like: “Why is my maintenance team performing tasks X, Y, and Z on these days for different pieces of equipment?”

The answer is likely: “It’s the way we’ve always done it…because the calendar tells us when to act.”

List all the assumptions you have for each task. As you break down the reasons you’re performing specific tasks, you’ll identify inefficiencies (e.g., too many emergency repairs on chiller B), which further indicates data you need to track (e.g., historical energy use for all chillers).

Many key performance indicators (KPIs) will depend on your goals, but all facility managers should track the following:

Work order-related KPIs

Work orders (WOs) | Compare scheduled WOs versus completed WOs, time spent on each job, and track the backlog of WOs. |

Machine uptime versus downtime | A measurement of the time that important assets are non-operational and the associated costs. |

Percent of reactive work | The ratio of planned work and unplanned, reactive maintenance tasks. |

Facility-specific KPIs

Energy costs and performance | Submetering with sensors on individual floors of a building offers energy use for just that area, revealing spots where consumption is higher than normal. |

Occupancy | Sensors are available to detect when occupants enter a specific space of the building, and over time, you can see a trend of the most occupied times of the day and week. |

Occupant comfort | An effective low-tech method to measure comfort is with an occupant survey. If the people in your building are uncomfortable or feel unsafe, they’re likely to let you know. |

Water management | Water flow sensors and utility readings are invaluable, as restrooms and HVAC systems account for the majority of water costs in commercial buildings. |

Monitoring the most appropriate maintenance KPIs is a step towards a smarter maintenance strategy. Since your facility management challenges are unique, your KPIs should be too—an industry-specific software vendor can help you collect the data you need to make the best decisions.

Beyond adding sensors to older machines, Gartner says modern equipment and software is capable of leveraging data to perform simple maintenance tasks on its own.

_

“Asset intelligence will also extend to self-diagnosing faults beyond alerts, initially to inform maintenance planners and operators, but eventually to perform corrective actions (internal adjustments) to prevent failure and extend asset life. Think of this as the 21st century equivalent of a speed governor on a steam engine, but at a much larger scale, with more precision and with more immediacy.”_

– Gartner analysts Kristian Steenstrup and Nicole Foust

WHERE TO START: Review every planned maintenance task and the underlying assumptions for each, then identify the appropriate KPIs that will help improve inefficiencies. Use these KPIs when evaluating software to determine which system is designed to use this data for more proactive maintenance.

3. Predictive analytics: Turn your data into valuable advice

Combine sensor data with a strong facility management system and you have the recipe for “just-in-time” predictive maintenance that greatly reduces costs, labor time and unplanned downtime.

With calendar-based maintenance, you service an asset every 90 days, for example, because you may have best practices from the original equipment manufacturer or some historical data to guide you.

Moving beyond that, sensor data offers more historical data as well as early indications of problems before they occur so you deploy resources only when necessary.

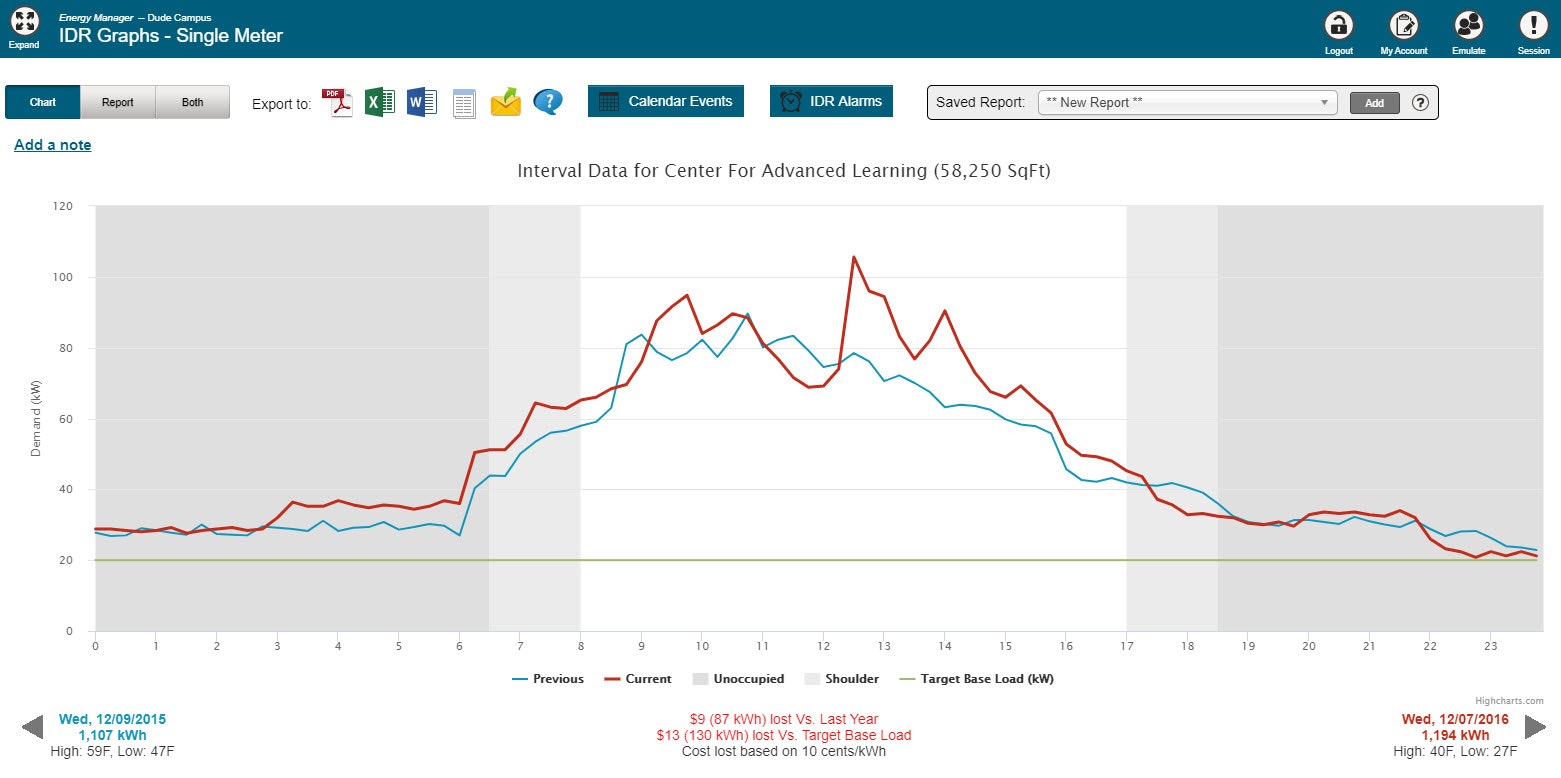

A view of energy meter readings in Energy Manager

The screenshot above is a typical view users will see for the energy use, vibration, temperature, pressure, or other indicators for each asset or area of a building being monitored. Enter your own upper or lower thresholds for each reading and dictate what the system should do if the asset crosses them—you can have the system send you a message, create a work order, or make changes automatically. Keep in mind, to get the best actionable advice from the analytics, you’ll find more success with a vendor who has experience with your type of facility.

WHERE TO START: Evaluate software vendors who have experience with your particular asset and building types and an industry-specific system to receive the most effective recommendations from the system. A strong understanding of your own assets will help you find the most effective predictive system.

Moving toward a smart maintenance strategy

If you plan to improve your maintenance strategy, you must leverage the data in your building.

As the technology becomes smaller, cheaper, and more powerful, it’s simple to collect this data, prevent expensive failures, and extend the life of critical assets using sensors and facility management tools.

Here are your next steps:

Review our latest Frontrunners for the top facility management software to see which systems users say offer the most value.

If you want to find something quickly, schedule a free chat with our advisors now to find a system that matches your specific needs.