Pedal to the Metal: Using Your ERP to Plan Production Cycles

Planning production cycles is a lot like designing a bike: Because each component relies on the others to keep moving forward, one minor breakdown can leave you (or your business) scuffed and scarred.

It’s why more and more businesses are turning to process-focused software for their production planning efforts, ERP software chief among them.

Small and midsize businesses (SMBs) have traditionally lacked access to the technology and analytics tools necessary to fully optimize their production cycles, causing inaccurate inventory counts and wasted dollars. But with fewer and fewer barriers to entry, ERP software is more SMB-friendly than ever before—and turning conventional wisdom on its head.

Manufacturers that plan their production cycles with ERP data will have unprecedented insight into every stage of production. To anticipate production outcomes more efficiently and effectively, your ERP data is essential.

Here’s what we’ll cover:

Production Cycles and ERP Software, Explained

Optimize Workflows With Improved Resource Allocation

Reduce Human Error and Boost Efficiency With AI-Assisted Automation

Forecast More Accurately With Advanced Analytics Dashboards

How to Plan Your New Planning Process

Let’s get down to business.

Production Cycles and ERP Software, Explained

Production is the lifeblood of the manufacturing industry—and cycles make it go.

From planning and scheduling to execution and distribution, manufacturers need a reliable and efficient production process to meet ever-fluctuating consumer demand.

Unfortunately, increases in make-to-order accommodations and diminishing lead times complicate an already competitive manufacturing landscape, making it even more demanding for organizations with limited resources.

In other words, a finely tuned production cycle isn’t enough to compensate for such unpredictability; to stay competitive in this rapidly evolving industry, you need deeper insights and the ability to adapt on the fly.

That’s where ERP software comes in.

Optimize Workflows With Improved Resource Allocation

When planning production cycles, knowing how, where and when to allocate resources is paramount. Confidently determining how to distribute labor, verify machine availability and determine the optimal product mix can be next to impossible—if you don’t have the data to do it.

ERP software doesn’t just have more data than any other solution, it has more useful data.

By incorporating insights from across the organization, ERP systems help businesses:

Flatten bills of materials by identifying waste and sourcing only the materials needed for production (a process known as material requirement planning).

Analyze machine usage rates to ensure that the best equipment is being used with the fewest amount of resources, resulting in a leaner factory floor.

Map their inventory to ensure products are moving through the supply chain with maximum efficiency.

Optimize every stage of the manufacturing process and produce winning production schedules.

![]()

Job tracker module in Global Shop Solutions ERP (Source)

In short, ERP software can help your manufacturing business fine-tune its workflow in a way that boosts productivity and reduces waste.

Reduce Human Error and Boost Efficiency With AI-Assisted Automation

Machines are taking over.

Well, not really—but they’re taking over the business world.

Gartner predicts that in the next two years, 80 percent of all emerging technologies will rely on artificial intelligence (AI) as the centerpiece of their infrastructure (full report available to clients).

AI is one of the centerpieces of ERP software, and its ability to automate routine processes is already impacting manufacturers in a big way.

When evaluating production cycles, manufacturers can use ERP’s AI-enhanced process automation to:

Monitor supply levels and adjust production in a way that avoids surpluses or shortages and keeps inventory balanced.

Reduce downtime through real-time equipment monitoring and predictive maintenance capabilities.

Process purchase orders and automatically generate work orders and plans for production.

Adjust design blueprints to use the least amount of materials necessary while ensuring optimum product quality.

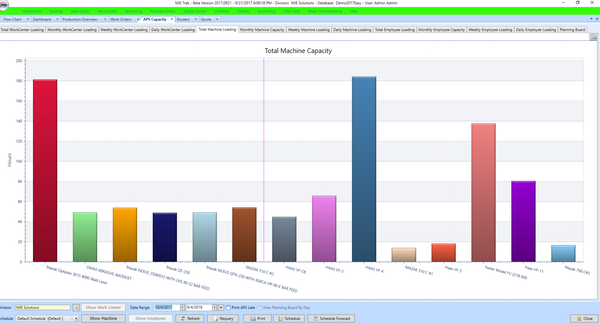

Machine capacity functionality in MIE Trak Pro (Source)

What’s more, it can do these things faster and with greater accuracy than any human ever could, freeing up personnel to focus on analysis-based tasks. As the technology matures, manufacturers will reap once-unattainable benefits—and you’ll have your ERP to thank.

Forecast More Accurately With Advanced Analytics Dashboards

The best way to predict the future is to analyze the past, and ERP software has historical data in spades.

Unlike other standalone components, ERPs consolidate data from disparate business processes into a unified whole. This is especially critical when planning production cycles, given how the totality of the manufacturing process depends on everything from human resources to supply chain management.

With ERP’s advanced forecasting capabilities, manufacturers can:

Predict demand with historical sales data—down to the region, time of year and even individual client—making for more accurate, fact-based production schedule planning.

Anticipate supply viability based on average lead times and materials availability, resulting in a more efficient procurement process and consistently balanced inventory.

Assess probable financial outcomes by weighing income and spending projections, as well as the always-fluctuating costs of materials and acquisition.

Analytics dashboard in Paragon ERP (Source)

ERP software presents these metrics with aesthetically pleasing, easy-to-comprehend analytics dashboards, all of which are highly customizable—so you can plan your production cycles using only the most relevant information.

How to Plan Your New Planning Process

OK, so ERP software helps make production planning a breeze. Now what?

Before you implement any process changes, here are steps you can take right now to put your business on the path to production planning prosperity:

Audit your existing planning process. If you’re experiencing production cycle pain points (and if you’ve gotten this far, odds are good), the first thing you should do is assess the process you currently have in place. Identify deficiencies and inefficiencies, then consider whether ERP software can alleviate these problems. You can do the latter by checking out our ERP software page, complete with more than 150 product offerings, user reviews and a buyer’s guide.

Follow all the latest ERP market developments. With so many new features and emerging technologies, making heads or tails of the ERP landscape can be a slog. But worry not—we’re on top of it. Our Resources page is full of articles to help SMBs stay up to date on all the latest developments, including recommendations for how to address software-related challenges.

Give us a call. Still unsure about which ERP products can best address your production needs? Reach out to one of our industry-leading software advisors for a free one-on-one consultation at (855) 998-8505.

Note: The information contained in this article has been obtained from sources believed to be reliable. The applications selected are examples to show a feature in context, and are not intended as endorsements or recommendations.