Project Procurement Management: Navigating the Complex World of Suppliers and Contracts

In 2023, a staggering one-third of project managers grapple with procurement obstacles as their primary supply chain issue*, highlighting the importance of mastering project procurement management. When done right, procurement management ensures seamless planning, sourcing, and delivery of goods, services, and assets—setting your project up for success.

This guide is tailored for SMB leaders and inventory managers in retail, manufacturing, or e-commerce, who are determined to choose the right suppliers, manage contracts, and ensure timely deliveries, all while staying on budget and maintaining superior quality. This quick guide distills insights from Gartner [1] and features an expert's unique take on mastering procurement management.

What is project procurement management?

It is the process of obtaining necessary goods and services for a project by planning, executing, and controlling procurement activities. It involves identifying project needs, selecting suppliers, and managing relationships to ensure successful project completion.

David Reid [2], Sales Director at VEM Tooling (a plastic molding and manufacturing firm), takes a metaphorical approach to explain what procurement management is. Here’s what he says:

David Reid

Sales director at VEM Tooling

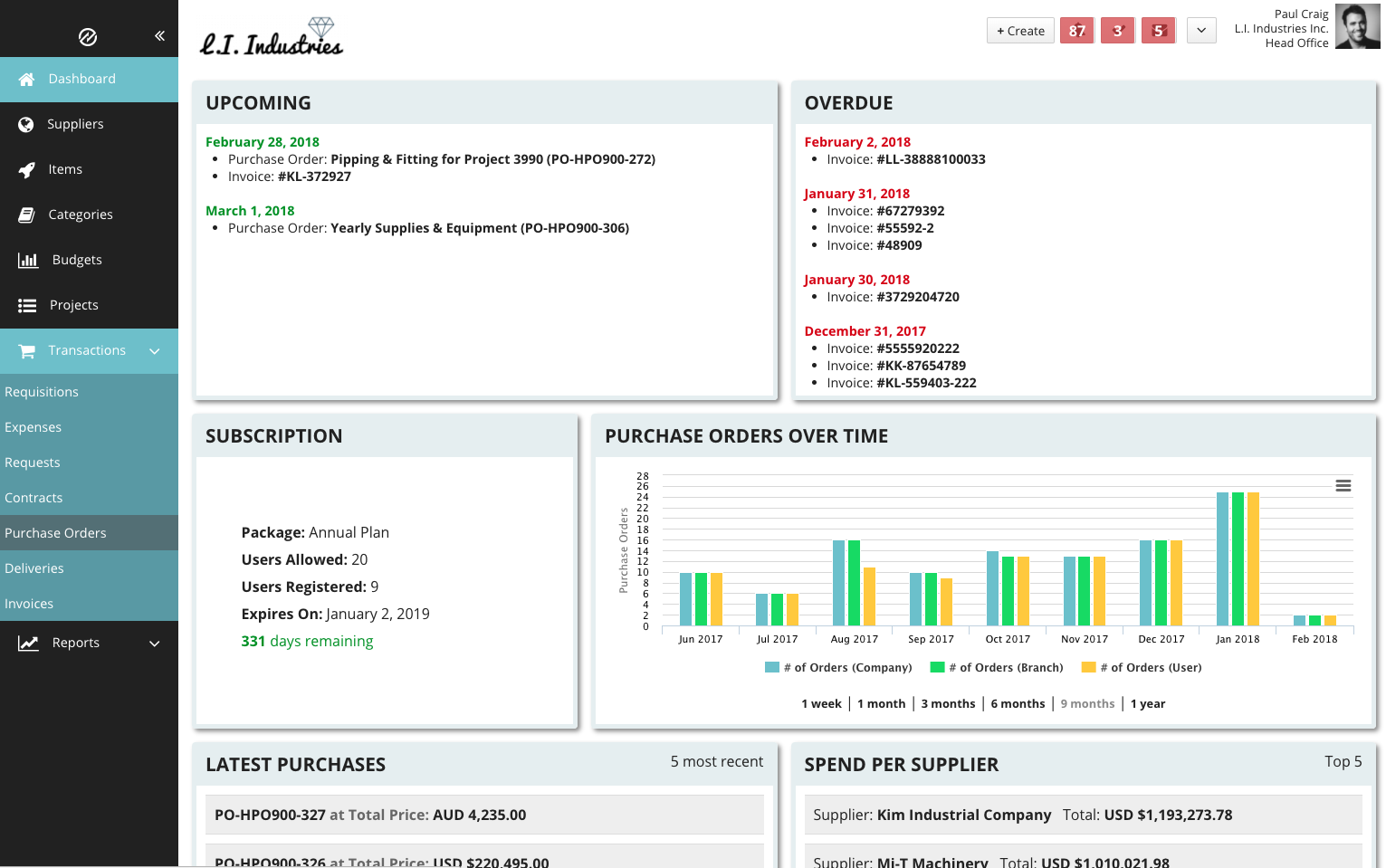

Procurement management software simplifies the entire process (including planning, conducting, controlling, and closing of procurements) by offering a centralized platform for managing procurement activities. It streamlines the identification of requirements, automates the creation of contracts, facilitates supplier selection, and tracks performance.

Example of a procurement management dashboard from Tradogram (Source)

What are the different procurement types used in project management?

When you understand the different types of procurement, you can easily optimize the process of acquiring goods, services, or works from external sources and ensure project success. There are three main types of procurement you may encounter—direct procurement, indirect procurement, and services procurement.

1. Direct procurement: Refers to the acquisition of raw materials, goods, or components directly incorporated into the end product or service.

Example: A construction company procuring cement, steel, and bricks for a building project.

2. Indirect procurement: Involves the purchase of goods or services that support the operation and management of a business but are not part of the final product or service.

Example: A software development company purchases office supplies, computers, and software licenses for employees.

3. Services procurement: Relates to the procurement of specialized services or expertise from external sources.

Example: A construction company hires an engineering firm to perform structural analysis and design for a building project.

Why is procurement management crucial to supply chain operations?

Procurement management holds a critical place in supply chain operations, as it involves sourcing, selecting, and acquiring the necessary goods and services from suppliers. David divulges his unique perspective on procurement management’s crucial role in supply chain processes. He says:

"The importance of procurement management lies in its role as a key driver for a project’s overall efficiency, effectiveness, and success. Procurement management is crucial to supply chain operations because it ensures that businesses acquire the right goods and services at the right time, in the right quantity, and at the right price.

I once witnessed a major automotive manufacturing company suffer huge production delays and financial losses due to weak procurement management. They chose suppliers based solely on low cost, neglecting to assess their reliability and capabilities. This led to a critical part being delayed, grinding production to a halt and resulting in massive lost revenue and penalties.

To resolve this issue, the company invested in supply chain planning software to develop a comprehensive procurement management process, focusing on supplier evaluation, risk assessment, and continuous improvement. As a result, they reduced its procurement costs by 15% and improved on-time delivery rates by 27%."

What are the pros and cons of project procurement management?

When managing a project, whether simple or complex, you must consider the factors helping (the pros) and hindering (the cons) your project. Doing so lets you navigate challenges and optimize your strategies, ultimately leading to smoother project completion.

Here are some benefits and drawbacks of project procurement management you need to know:

Advantages of project procurement management | Disadvantages of project procurement management |

|---|---|

Cost savings: By using effective procurement strategies, such as bulk purchasing, negotiations with suppliers, and bidding processes, you can save significant amounts of money. | Complex process: Since it involves a lot of documentation, legal requirements, and coordination with suppliers, it can be complex, especially for large organizations. |

Risk management: By carefully evaluating suppliers and contracts, you can avoid legal disputes, delays, and quality issues that can help you decrease costs and ensure timely project completion. | Limited flexibility: The procurement process often involves strict rules and regulations, which can restrict your ability to work with suppliers outside the procurement process. |

Quality assurance: By selecting reputable suppliers and using quality control measures, you can reduce the risk of receiving subpar goods and services and ensure top-notch project quality. | Additional costs: Procurement management can involve additional costs, such as legal fees, administrative expenses, and supplier management costs. These costs can add up and affect the overall project budget. |

Improved supplier relationships: Procurement management helps you build strong relationships with suppliers. This can lead to better communication, faster delivery times, and favorable contract terms. | Potential conflicts of interest: Procurement management can create conflicts of interest, especially if suppliers are involved in decision-making. This compromises the objectivity of the procurement process and leads to biased decisions. |

Procure your way to success with these best practices

Follow these best practices to be well-equipped to successfully manage your procurement activities and drive your project towards success.

Start with clarity: Define your procurement objectives and requirements for a strong foundation.

Plan strategically: Devise a comprehensive sourcing strategy using robust strategic planning software to optimize resources and timelines.

Choose wisely: Evaluate suppliers meticulously to identify the best fit for your project.

Negotiate skillfully: Work on obtaining favorable terms and conditions that benefit all parties.

Stay compliant: Adhere to all relevant regulations and legal requirements to avoid potential risks.

Monitor closely: Keep an eye on supplier performance to maintain quality and address issues proactively.

Embracing these best practices can help you ensure that you achieve an optimal project quality, reduce costs and control spending, as well as mitigate the risks.

Survey methodology

Supply Chain Management Trends Survey Data

*Software Advice conducted the Supply Chain Management Trends Survey in November 2022 among 300 supply chain professionals at small to midsize businesses in the U.S. The purpose of the survey was to learn about their supply chain experiences, challenges, and future plans. Respondents were screened to ensure their business has 1,000 or fewer employees and an annual revenue of $500 million or less.

Sources

Ignition Guide to Designing a Procurement Project Management Plan, Gartner

David Reid, LinkedIn