Supply Chain Segmentation: What It Is & How to Do It

A one-size-fits-all approach to sourcing, production, shipping, and processing returns is no longer effective. With today’s customer expecting quick shipping, visibility into the status of their orders, and an omni-channel experience, small and midsize businesses can struggle to deliver.

Let’s take a local bakery as an example. Supply chain management is required in order for the baker to get the raw ingredients and then to sell the finished products. But for this bakery to expand its business, such as delivering cookies to a grocery store for resell or shipping customized cookies to a customer in another state, segmenting the supply chain can help improve the process.

The grocery store will likely want a daily delivery, while only occasionally fielding out-of-state cookie shipment requests. By planning when to order the ingredients needed for each scenario, where to store the goodies for optimum freshness, and then how to deliver them to the two different customers, the bakery is using a supply chain segmentation strategy.

But we can break this down even more.

Here’s what we’ll cover:

What is a supply chain segmentation strategy?

3 tips for implementing a segmentation strategy

Support operational processes and planning with supply chain management software

What is a supply chain segmentation strategy?

A supply chain segmentation strategy optimizes different, specific processes for different needs or outcomes in order to serve a growing and diverse customer base with a range of product offerings.

For instance, local customers want the shelf fully stocked with your product line so they can browse and choose from your selection. But online shoppers pick and choose the exact product they want.

For the locals, you ensure products are getting delivered regularly. That segment of product could be grouped together in your storage facility, ready to be loaded all together to get to the store.

For the online shoppers, storing products by type with each specific product in the same location will make it easier for the team who fulfills online orders.

According to Gartner, CEOs across all industries are pressing for more growth and improved costs. In a Gartner CEO survey, 54% of respondents identify growth as the top priority, while 49% cite operational efficiencies. The report also states that many supply chains have embraced segmentation rather than settling on one process to meet all competing needs. (Content available to Gartner clients.)

As mentioned above, growth increases shipping and shipping can eat into a business’s bottom line if not consistently assessed and changed when needed.

Case Study: Neeme Inc.

One small business based in Las Vegas has made a supply chain segmentation strategy a core part of their culture. Busi Buthelezi is the chief operating officer at Neeme Inc., a small clothing business founded in 2016.

Busi saw the opportunity to design and sell men’s shirts when her partner, professional poker player Andrew Neeme, was consistently asked on his YouTube channel if he had merchandise available. Today, the company designs and sells around 1,000 pieces of clothing and accessories a month.

Expanding internationally has been the focus for the company but their domestic customers still need the same experience they have always had.

Busi says, “[at] the local level, we segment the final product by weight and packaging type. This information allows us to choose the freight carrier with the most competitive pricing for the local regions. By partnering with multiple freight carriers, we can control the cost and continue to offer complimentary domestic shipping.”

So what can you do to get started on segmenting your supply chain? We’ll cover that next.

3 tips for implementing a segmentation strategy

The first step you should take is to document the current supply chain process. Write it down. Draw a diagram. Create some sort of visual of the end-to-end process of your product. This helps ensure you review each step and also helps to identify gaps and identify grey areas.

1. Take partners to document your supply chain process

Doing the exercise alone can lead to missing segments. Other departments, such as logistics and sales, could have insight to points in the supply chain perhaps you were unaware. They may also have competing needs. Your supply chain segmentation strategy could be an opportunity to address their needs.

Start by sharing the end-to-end process visual of your current supply chain. The diagram/flowchart gives you both a detailed and high-level view of where and how your product is moving. Discuss their current pain points and where in the process changes could be made to address them.

Let’s return to the bakery for an example. The sales manager and logistics coordinator draw out their supply chain process on a whiteboard. When they step back to review, it becomes clear that there are some issues. The sales manager puts in the orders to arrive on Mondays, but the logistics coordinator has that day off. Product has been sitting in the loading area for a full day. Coordinating schedules is an important part of a supply chain segmentation strategy and improves the partnership between the areas.

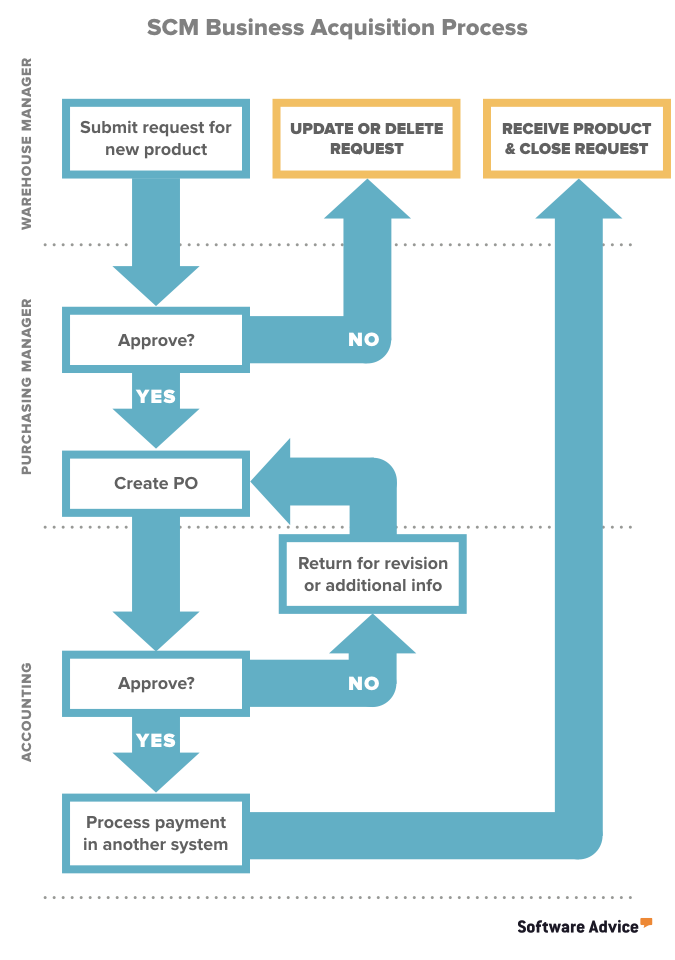

An example of a supply chain business process flow chart (Source)

Be sure to follow up with updated process documentation. Checking in will build trust which will be crucial for improving the efficacy of the supply chain at the core.

2. Test new changes

Implementing a new strategy is not a one-and-done deal. Make incremental process changes, evaluate the impact, and adjust accordingly. Start with small changes, such as changing the arrangement of products in your warehouse discussed above. Then review the fulfillment time to see if there has been a reduction. Relocating products to be geographically closer to customers could be an option, too.

Or perhaps you offer both “off-the-shelf” product options and customizations. The former could be housed as close to the customer as possible, where centralizing the production of the customized offerings could reduce headcount as you would have one team doing the product customizations instead of several local teams.

Being adaptable and testing changes are focuses for Neeme Inc. Testing small process changes and being open to adjustments along the way are important. Busi says you should “[decide] on the experience you want to offer your customer and find solutions that will allow you to provide that experience and still remain profitable. Be willing to change/tweak your supply chain strategy when new options become available.”

Pick two or three goals at first. Use your flowchart to track and evaluate the impact of these changes as you make adjustments toward these goals. If you choose to increase speed to fulfillment, reduce cost of labor, and reduce percentage of product returns, write the current numbers on the flowchart you created.

Then assess these numbers incrementally, perhaps every two weeks, and write the new numbers below. This will give you a way to see which changes have had a positive or negative impact toward your goals.

3. Start now!

Don’t wait until next year. Make small changes now in your current processes (referencing and updating the process flow chart). Addressing bottlenecks and redundancies in fulfillment first is often a good idea. If your product is slow to get out of the warehouse for online orders due to a setup that is designed for deliveries to a store, rearranging the setup to address both needs can be done without waiting for the next calendar year.

Planning changes that will require more time, such as tracking the status for an individual order at each step, can start now, too. Implementing a supply chain management (SCM) software tool can be a part of this effort. The next section will dive into how an SCM can help.

Support operational processes and improve planning with supply chain management software

An SCM software tool can help alleviate pain points commonly experienced when manual methods are in place. Examples of where an SCM can help include:

Automation: Reduce errors and time by eliminating the Excel sheets and even pen and paper still widely used for forecasting, budgeting, and invoicing. Tracking speed to fulfillment can be automated. Also, the software can run reports in seconds, instead of the days it can take to aggregate the data manually.

Communication: Support the way product owners, vendors, accounting, and even drivers communicate their needs and expectations to each other. The SCM serves as a single source of truth for product acquisition, transport, replenishment, and returns.

Visibility: Identify process inefficiencies and missed opportunities due to a lack of visibility of where product is going and when.

Modernization: Tools like barcode scanners can be invaluable but only if they are integrated into your system properly and have updated capabilities. Each time an item is scanned as it arrives at the dock, the storage location, or the warehouse or when it’s scanned upon sale, the software tracks the time and user.

Additional features such as invoice creation and approval workflows allow accounting and operations to be on the same page and resolve issues quickly and with more accurate information. Many SCMs provide dynamic pricing adjustments of which accounting and operations will have visibility and tracking to make return processing easier and improve forecasting to increase the bottom line.

Selecting the right tool for your business is crucial as it is an investment in your growth and performance. Cost, features, the SCM’s support model, and volume capability are each important aspects to consider as they can vary greatly from tool to tool.

Use the goals you identified after writing out the current supply chain process, taking partners to flesh it out, and testing small changes discussed in the tips above. Each of these steps will help you create the best supply chain segmentation strategy for your business. Your strategy should cover the entire lifecycle of a product and support all areas of the business in order for your business to fully realize the benefits of segmentation.

Now go, segment away!

Looking for insight to help you select the best SCM for your supply chain segmentation strategy? Click here to check out our detailed list and reviews of SCM software.

Or if you prefer to talk with a real person, our expert software advisors are ready to help! Call us at (844) 680-2046 for a free 15-minute consultation that can help you find the best supply chain management software for your business, no matter the size.