3 Critical Technology Disruptors You Should Be Talking About

Think back to the last time you tried a new restaurant. Did you search the yellow pages to find it? Use a folded up city map to get directions? The odds that you did those things are slim to none.

Digital disruptions are very real, and your business needs to stay proactive to keep up.

But knowing what’s hype and what’s worth incorporating into your business strategy can be confusing. To help, this article lists the top three technology disruptors that we think businesses need to know about.

What is a technology disruptor?

A technology disruptor is a new product or process in digital or automation technology that is currently impacting manufacturing, marketing, shipping, and ideating processes. Another key factor is the tech’s viability to continue to change the landscape of the industry.

We’re not talking about tech that could or will likely impact businesses in the next 10 years. These disruptors are giving proactive businesses a competitive edge and hurting the ones falling behind in adoption.

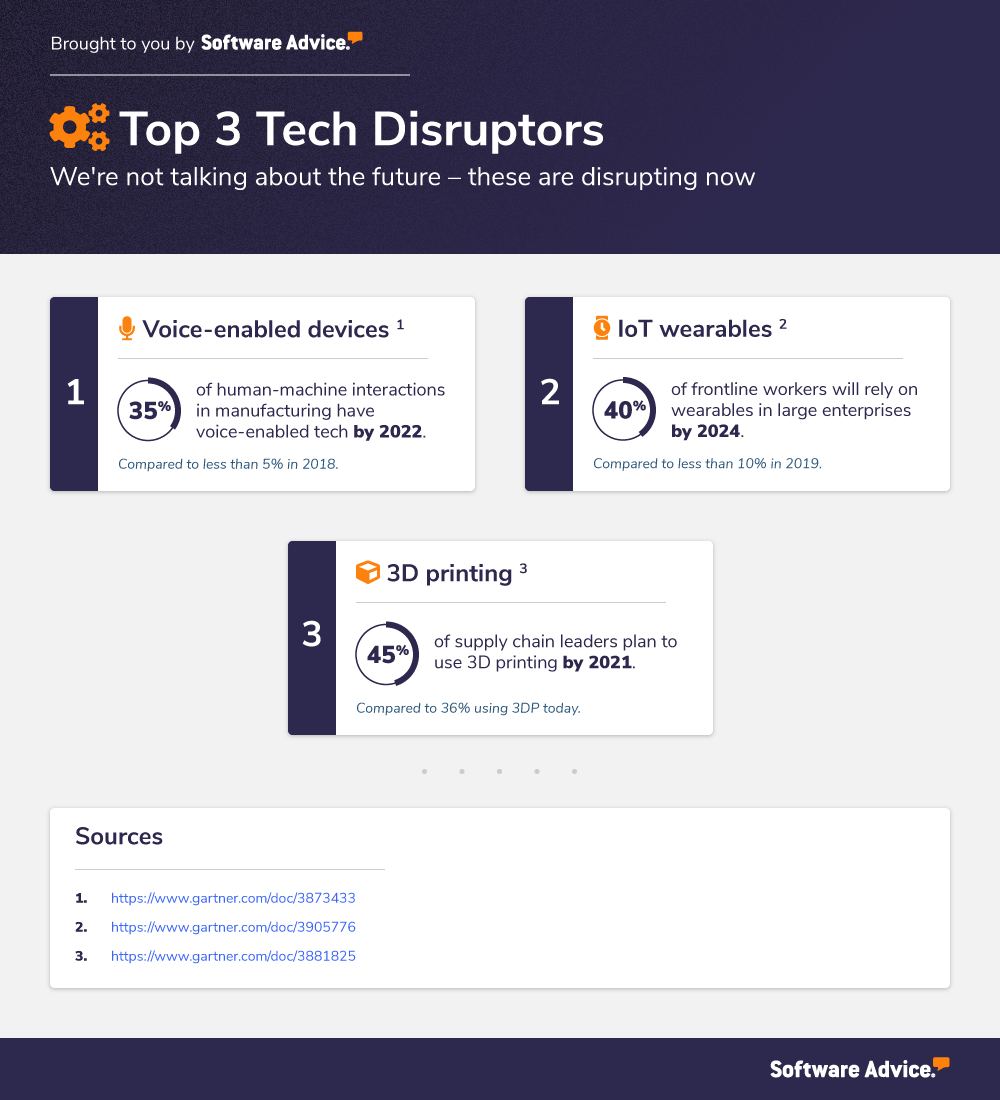

Let’s dive right in. Here are the top three along with some stats to back up our position.

1. Voice-enabled devices

Voice-enabled devices represent a collection of digital technologies that use a person’s voice to prompt an action, such as making a phone call, ordering parts, or giving directions.

Software can either be connected with a voice-enabled device—for example Amazon’s Alexa for Business integrates to the popular CRM system, Salesforce—or a custom device can run an artificial intelligence-powered voice-enabled program in order to perform a physical function.

An example of the latter is a robot, named Pepper, who was trialed in the Munich airport to give passengers flight information. Pepper was not only helpful but also provided some stress relief to weary passengers as they were delighted to interact with the friendly robot. Oh, and she can dance:

2. IoT wearables

With the internet and broadband networks saturating our airwaves, we can now connect devices to cloud environments and sync them to our phones more easily than ever.

The Apple Watch and FitBit are examples of internet of things (IoT) wearables that have altered the way people do everyday activities, such as getting the weather forecast and tracking their heart rate. (Remember back when you called “311″ on a landline to get the day’s weather? Crazy times.)

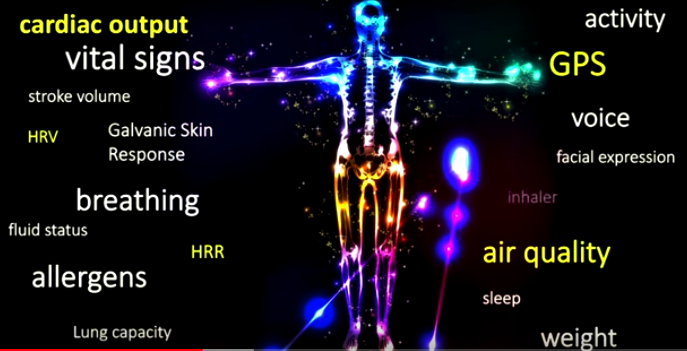

Examples of what medical IoT wearables can track now (Source)

While consumer demand and adoption has moved much more quickly than business use has, there are now wearables on the market disrupting the way business professionals work. The Apple Watch offers a “Movement Disorder API” to track Parkinson’s symptoms, warehouse workers can use “smart glasses” for improved order picking, and hospitals can use a flexible, band-aid like device, TempTraq, to monitor the temperature of a sick baby.

Check out our article with examples of wearables for construction.

3. 3D printing

3D printing, also known as additive manufacturing, is the process of creating a 3D product based on a blueprint from a digital file. The real value of 3D printing comes in the “additive” approach—where the material is laid down and layered to the exact dimensions determined in the blueprint. There is no wasted material, as there is in the opposite approach of cutting out the desired parts from a larger chunk.

Example of 3D printing in action (Source)

Gartner, the research group, recommends that early adopters of 3D printing should focus on rapidly and repeatedly prototyping parts whose final design will be produced in metal or ceramic, even if they are produced with conventional manufacturing technologies.

Gartner also recommends considering opportunities in making thick-walled tooling, jigs, and fixtures used in existing manufacturing processes, or for short-run production where injection mold costs are not financially justifiable. (Full report available to Gartner clients only.)

Check out our article that gives an in-depth look into 3D printing for manufacturing here.

Well, there you have it! Tweet me if you have comments or questions @AnalystOlivia. I also check my email on the reg—message me at olivia@softwareadvice.com. But definitely don’t call and leave me a voicemail. It’s not 2002.

And if you’re ready to upgrade your business with new software, our expert advisors are here for you. Give us a call at 844-686-5616. A 20-minute chat can help you decide on the best warehouse management, manufacturing management, supply chain management, or medical software—plus much more!