Access Delta WMS

About Access Delta WMS

Access Delta WMS Pricing

Starting price:

£75,000.00 one time

Free trial:

Not Available

Free version:

Not Available

Other Top Recommended Supply Chain Management Software

Most Helpful Reviews for Access Delta WMS

1 Review

Hamilton

Warehousing, 11-50 employees

Used daily for more than 2 years

OVERALL RATING:

2

EASE OF USE

3

VALUE FOR MONEY

2

CUSTOMER SUPPORT

1

FUNCTIONALITY

2

Reviewed January 2019

Works in principle, but vital features missing

Delta has been an improvement from our old system (which was very outdated), but it is a disappointing system when looking to optimise basic efficiencies. The support is good if there's an easy answer, otherwise it tends to get closed off as an unknown issue.

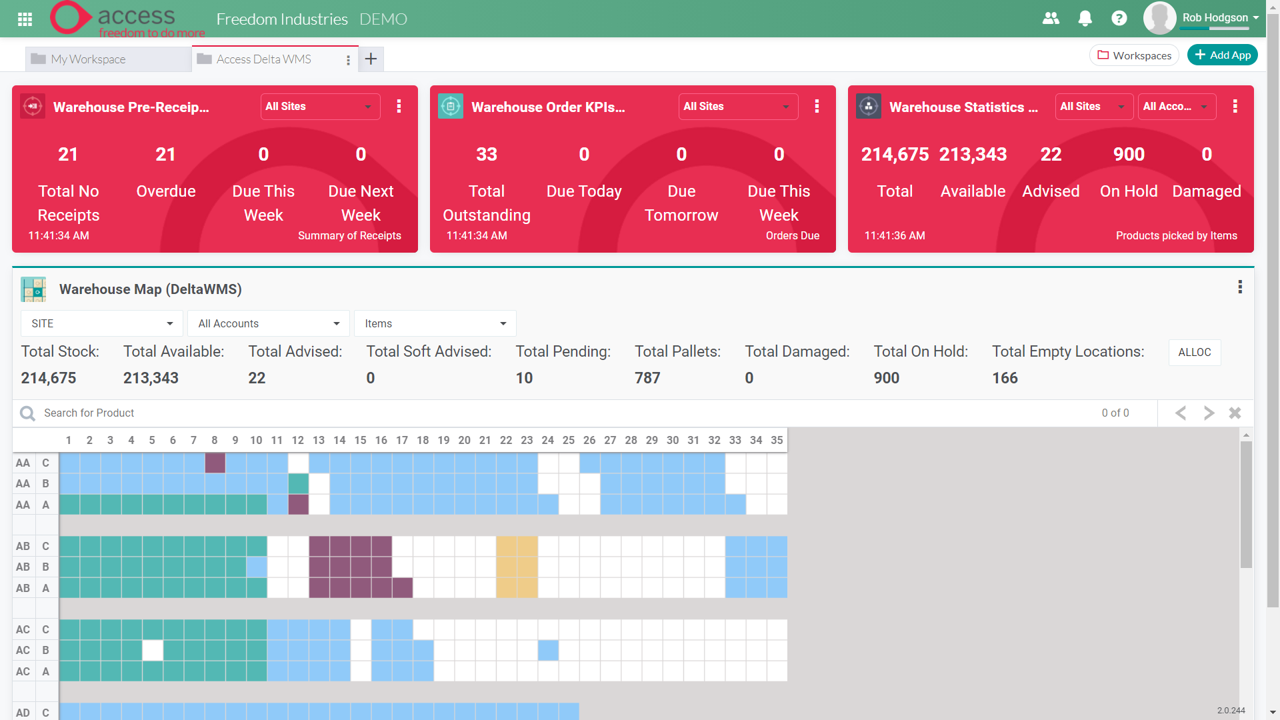

PROSVisability for Pre-reciepts, orders and loads the 'pools' make it easy to see what status orders are in. We've used Delta for over 2 years so the basic functions work.

CONSSome features that should be on any WMS are not there, such as picking and putaway interleaving, nor location sensitive picking (i.e. showing a pick near where you are). The putaway process shown in training was complicated, and we were told the only other option was to wait until a full load is tipped, booked and confirmed before any stock can be putaway - we have recently found there is another putaway method that is unbelievably simple, and can be used as soon as the first pallet is received. You are limited to 1 screen at a time, cannot have a report open and look at stock level at the same time, or have more than one order screen open at once.