A Guide to Manufacturing Software Pricing Models

Pricing your products and services can be daunting. If you work in the manufacturing industry, you know how competitive it is, so the pricing plays a vital role in how innovative your manufacturing company can be.

In addition to the pricing strategies, manufacturing firms must choose the right pricing and payment model in order to make their value-based pricing approach as effective as possible. Additionally, manufacturers are shifting from traditional pricing models such as pay-per-instance based on time and material to new pricing models such as subscriptions and freemium pricing models.

Keeping this in mind, we’ve put together a comprehensive guide to help you compare the pricing of top-rated manufacturing solutions. You’ll also learn how manufacturing tools are licensed and priced (including the pricing of top systems), and the full scope of manufacturing software’s pricing range. Ultimately, this will help you find the ideal product that fits your price point.

How is manufacturing software priced?

The price of manufacturing software depends on the specific features you need, your business size, and the industry you’re in. The other factors affecting price include additional modules, training, initial implementation, number of users, and ongoing support.

Pricing of a manufacturing software really depends upon your answers to the following questions. These will help you understand your business needs and identify how much money you’re likely going to spend on manufacturing software.

1. How many users will be interacting with this software?

2. What is the size of your business: Small, medium, or enterprise?

3. What kind of software features do you need: Basic or advanced?

4. What kind of pricing commitment are you comfortable with? Subscription-based or a long term deal?

5. Does free or open source software address your business needs?

6. Does the software offer any add-ons? If yes, what all will you be needing?

Based on how you answer the above questions, the same system could cost you hundreds of dollars less or thousands more. For example, Megaventory can cost as low as $150 per month or all the way up to $1,900+ per month, depending on the number of users and transactions primarily.

Manufacturing software price ranges

Manufacturing software vendors, like those in many other industries, typically offer a couple of purchase options depending on your current infrastructure and budget. We created a range of each type.

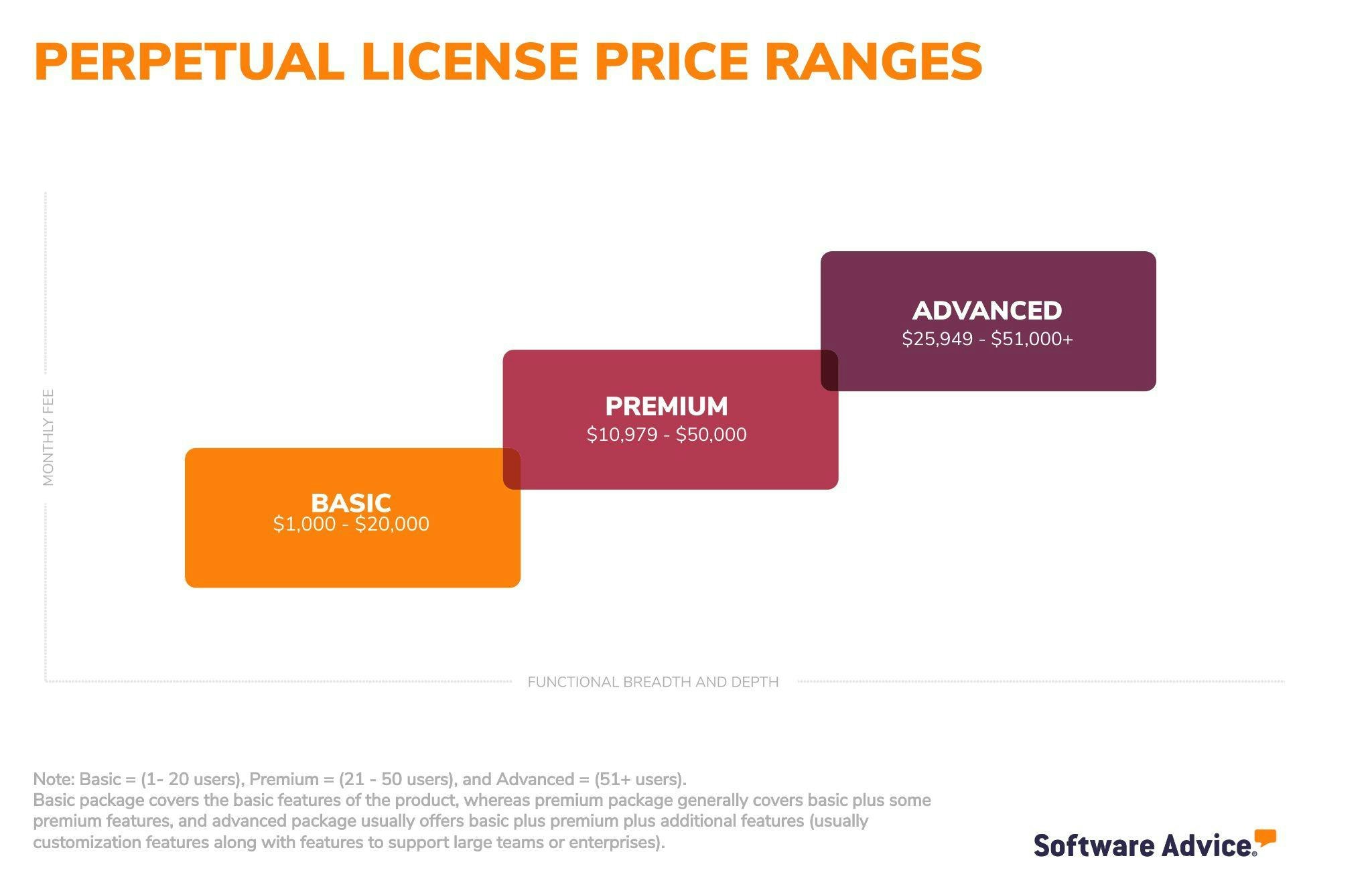

Perpetual license models require upfront payments for unlimited access to the system for as long as you need it.

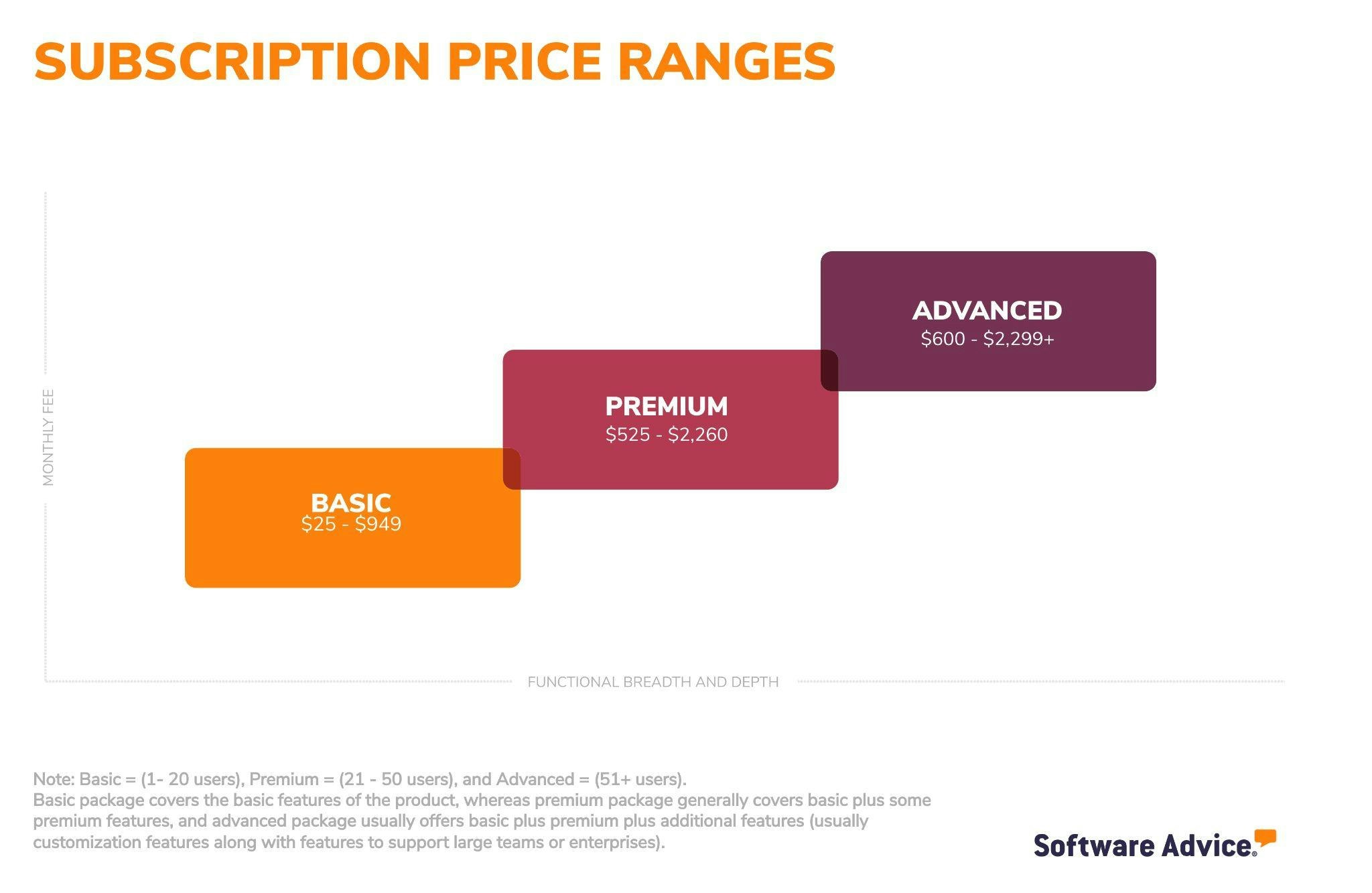

Subscription pricing models don’t typically require upfront fees and are paid for in a monthly or annual subscription.

Manufacturing software can start as low as $25 and run as high as $949 per user, per month while one-time license fees start around $1,000. For advanced accounting systems with more users, you can expect to pay closer to $2,299+ per month or $51,000+ for a license. Some providers offer free versions with limited functionality.

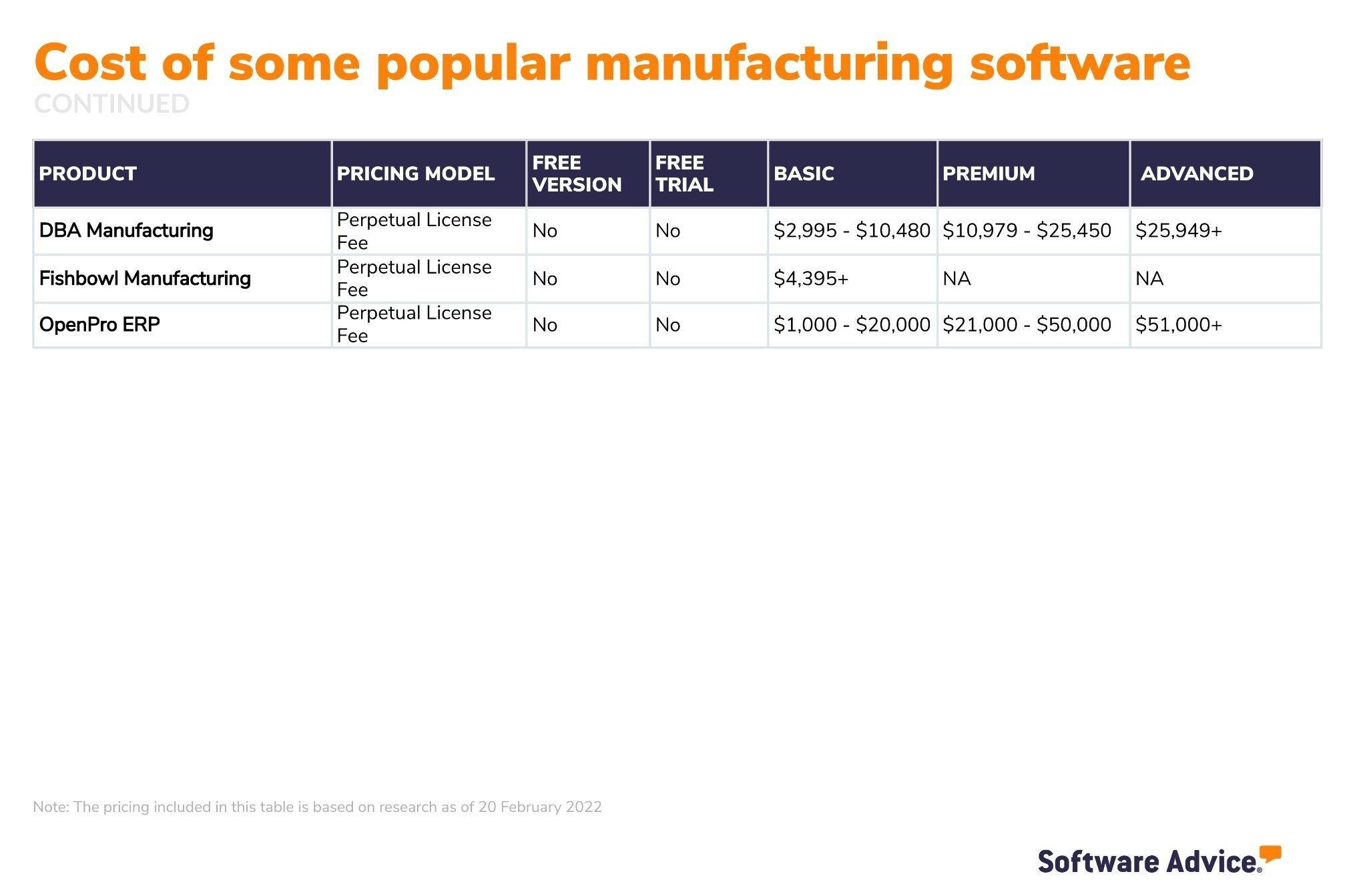

We can classify the different pricing plans based on the number of users as basic, premium, and advanced. The price for these three pricing ranges goes lower to higher as the basic plan covers just a few basic features of the management software, whereas premium plans include basic and advanced features. Also, the advanced plan is the highest priced among the three due to more advanced features that support large teams or enterprises. For reference, below is a snapshot of some popular manufacturing software.

Only products with publicly available pricing information were included in this table. We summarized publicly available pricing sources including vendor websites as of February 20, 2022, beginning with the lowest monthly pricing (not including annual discounts) for packages that include the core functionality for a software category. We list pricing for more advanced packages (per user, when available) that also include the core software feature(s). As always, your company’s specific needs may differ and final pricing will vary.

A note on features:

Manufacturing software, also known as manufacturing ERP software, helps companies manage orders and schedule production jobs using accurate bills of materials and inventory management to ensure all components are available. In addition, we identify some related features that organizations purchasing manufacturing software may also need or wish to consider: sales management, quality control, capital budgeting, field service management, and warehouse management. The core or basic functionalities include bills of material, order management, production scheduling, and inventory management.

Manufacturing software upfront and recurring costs

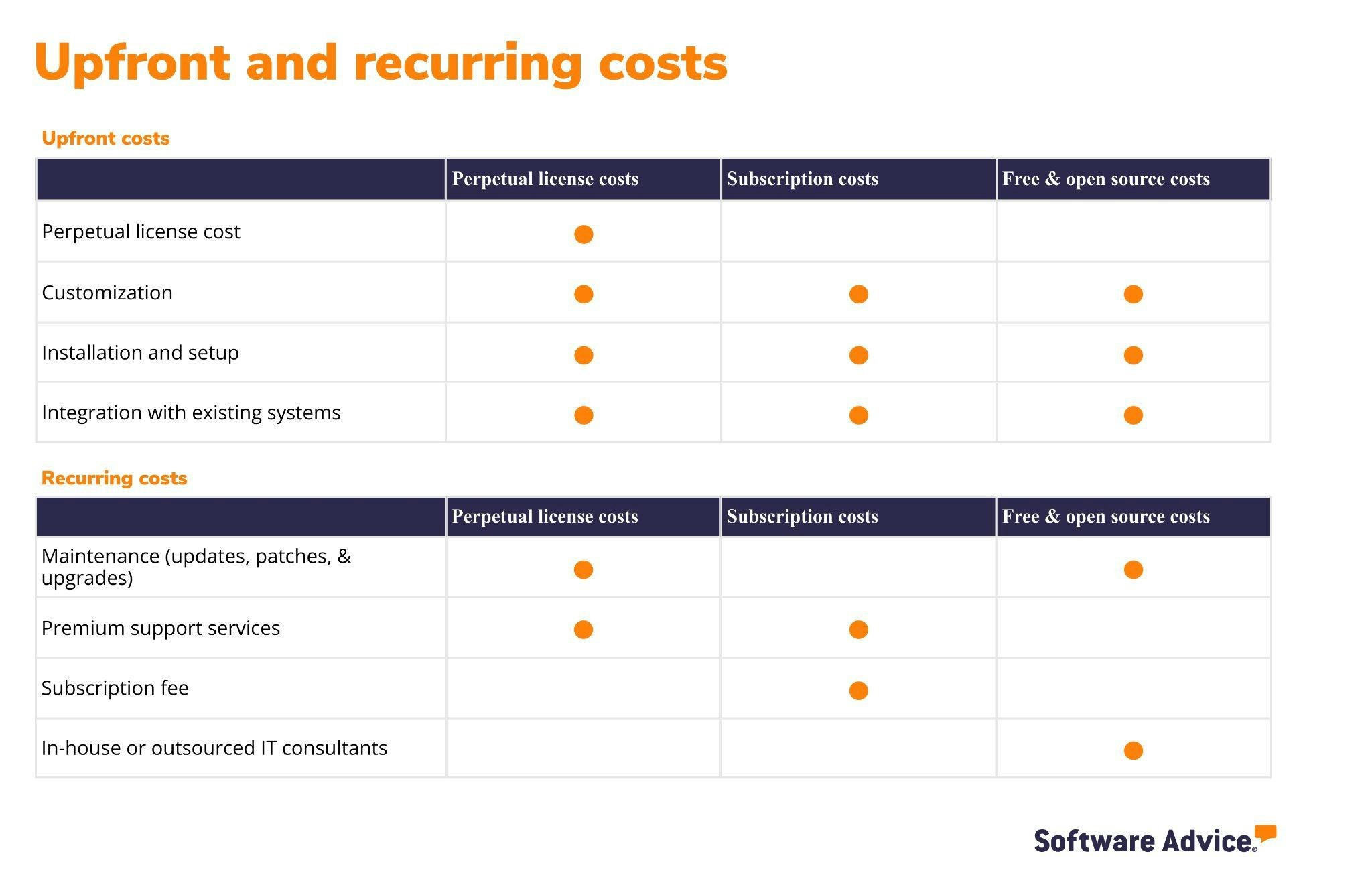

When we evaluate manufacturing, or manufacturing ERP software, price quotes, you’ll notice three main categories of pricing models: perpetual license, subscription license, and free and open source. You may already have a basic understanding of these options, but let’s consider the full upfront, recurring, and hidden costs of each:

1. Perpetual license

What it is:

You pay an upfront fee for the license to own the manufacturing software and use it forever.

Commonly used for:

On-premise deployments where the system is hosted and maintained in-house on your own servers.

Upfront costs:

A one-time license fee (can cost around $1,000 per user, per month)

Hardware (e.g., servers)

Recurring costs:

Monthly, annual, or ad hoc maintenance (e.g., updates, patches, and upgrades)

Premium support offerings (e.g., expanded phone support hours)

Hidden costs:

Customization (e.g., reporting and analytics capabilities)

Integration with existing systems (e.g., ERP, HR)

IT staff overtime (or hiring more IT staff) to maintain servers

2. Subscription license

What it is:

You pay a monthly fee to use the manufacturing software for a specific amount of time.

Commonly used for:

Cloud-based deployments, where the system is hosted remotely and can be accessed on compatible devices over the internet.

Upfront costs:

Installation/setup

Recurring costs:

A monthly subscription fee per provider/user (this can range from $25 – $949)

Premium support offerings (e.g., expanded phone support hours)

Hidden costs:

Customization (e.g., reporting/analytics capabilities)

Integration with existing systems (e.g., ERP, HR)

3. Free and open source license

What it is:

There are no fees to be able to use the manufacturing software, and you can use it freely, modify, and share it.

Commonly used for:

If your IT budget can’t accommodate a manufacturing software then you should try free tools to manage your project workload without burning a hole in your pocket.

Upfront costs:

Installation/setup

Recurring costs:

There are no recurring costs. You can use it freely typically with limited features.

Hidden costs:

Customization (e.g., reporting/analytics capabilities)

Integration with existing systems (e.g., such as accounting, project management, etc.)

Additional fees to expect

Once you’re familiar with the different pricing models, there are additional fees when implementing a new manufacturing software that are equally important to understand. These extra expenses are universal, regardless of your chosen vendor’s pricing model, so make sure you’re factoring the following into your budget:

Data migration: Transfer your clients’ data from your old software by exporting it as files that can be imported into the new system. This is often a surprise cost for buyers.

Training: Depending on how extensive staff training for the new system is, it can cost anywhere from nothing at all to several thousands of dollars. These days, vendors provide a wealth of free online training materials, such as webinars and how-to videos, that can help cut down on those extra costs. However, you might find it worthwhile to bring in an implementation specialist to get your staff up to speed as soon as possible in order to reduce costly downtime. This will typically cost more.

Maintenance and upgrades: It is important to know what maintenance and support services are being offered by the vendor and whether they are included in your software subscription or licensing fees. On the other hand, you might already have employees on your team to provide maintenance and support. It’s important to be sure of what support your software vendor offers, in case your team is unable to provide maintenance for the tool which could directly affect the ROI that your software was intended to deliver.

Hardware and IT: Is there any need to make additional purchases or enhancements to your existing infrastructure to implement the software? A common requirement might be the need to upgrade individual employee hardware, such as computers or mobile devices.

It’s important to take these often-overlooked costs into account before you begin evaluating vendors. This way, you can add them to your budget at the start.

What are the best manufacturing software packages?

Do the manufacturing tools listed in this guide fall within your software budget? If they do, compare their features and read real user reviews of more than 100+ similar products listed on our manufacturing management category page.

Note: This article is intended to inform our readers about business-related concerns in the U.S. It is in no way intended to provide financial advice or to endorse a specific course of action. For advice on your specific situation, consult your accountant or financial consultant.