Amper

About Amper

Amper Pricing

Pricing varies $75-100/machine based on machine type, quantity and length of contract

Free trial:

Available

Free version:

Not Available

Most Helpful Reviews for Amper

3 Reviews

Nick

Machinery, 11-50 employees

Used daily for less than 2 years

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed August 2021

Look no further for easy to use and deploy CNC machine monitoring

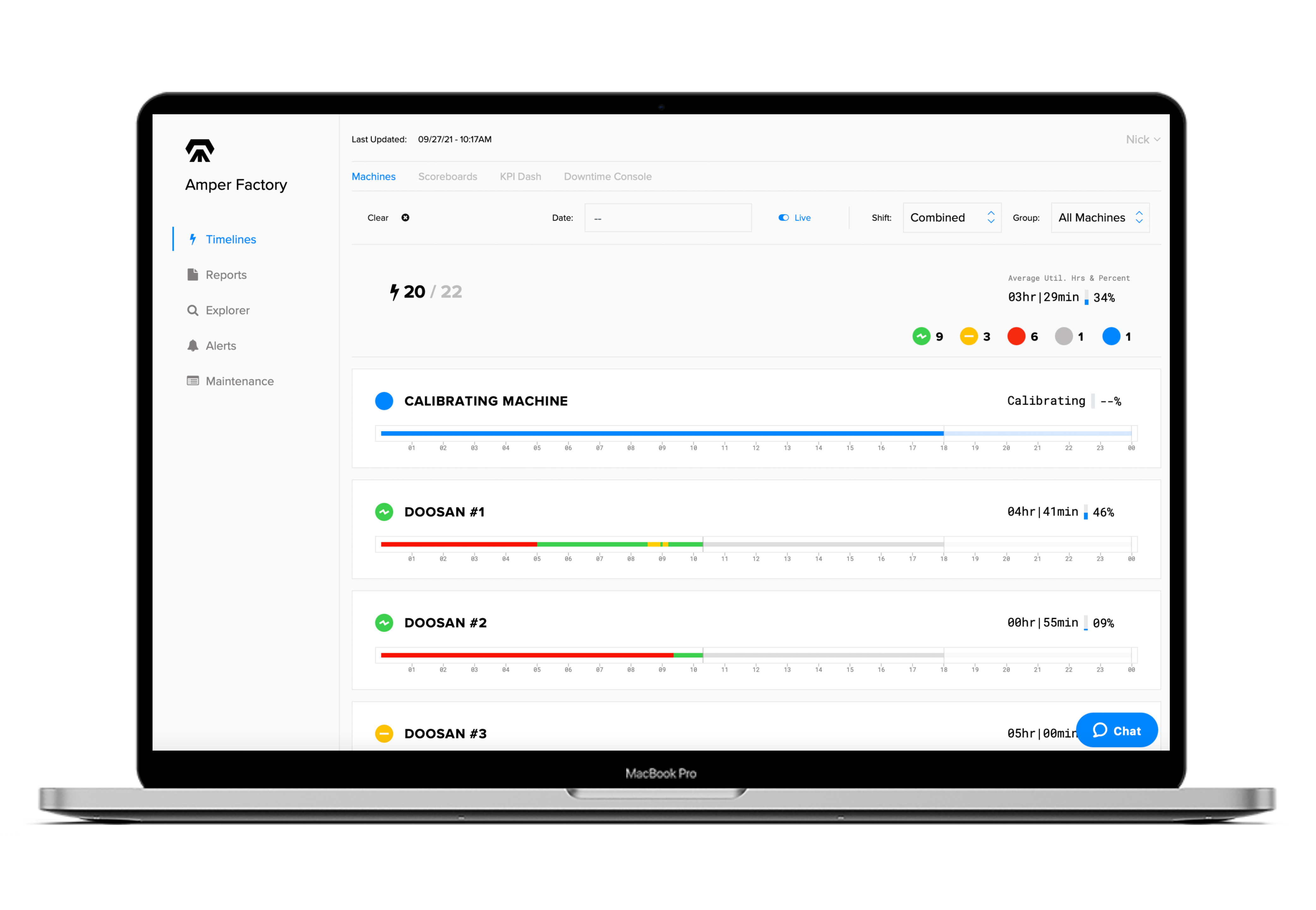

Amper answers the question of which machines are running vs in setup, vs unexpectedly down in real time. The reporting features also allow you to go back in time to analyze data and understand your shop's performance and capacity in more granular detail.

PROSAmper's product is incredibly easy to deploy and to use compared to other solutions we looked at. It also happened to be the most cost effective, which is an excellent combo!

CONSThe graphical interface could be improved (though I've noticed significant improvements since we started working with it).

Reason for choosing Amper

Cost and ease of deployment puts Amper into a league of it's own in this space.

Karyme

Automotive, 201-500 employees

Used daily for less than 2 years

OVERALL RATING:

4

EASE OF USE

5

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed August 2021

Amper as an OEE tool in SWD

The costumer service experience is really good with Amper. They keep working with beyond the implementation stage.

PROSIt helps us to understand our machine utilization in real time. It has given us more visibility of the problems that we have with the different machine so it is a really helpful tool for continuous improvement. The tablet app is nice so that each operator can interact easily with the system and be aware of their own OEE in real time. As part of management team it is quicker to have an overall view of the production situation of the plant before even having to spend hours walking out the plant floor.

CONSThe reporting part could be better. Still working on implementing production counts so that we can have more metrics out of this system.

Reason for choosing Amper

I know that Amper has been easier to install and interact with than other products that my company has tried in the past.

Bob

Machinery, 51-200 employees

Used daily for less than 12 months

OVERALL RATING:

4

EASE OF USE

4

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed August 2021

Overall Amper Process

In manufacturing you hear allot that this machine is down allot. But what really is allot and what are the reason codes 'why" the machine was down. Amper gives us that data that quantifies where the problem areas are so you can schedule to work on them.

PROSFor me I like the real time data it gives you and how the software makes it easy to split up the different work stations.

CONSCurrently still having trouble with the operators making comments or notes in the system. The operator currently has to tally down to see the complete note instead of getting the comment in one snap shot. Communication is a very important tool so the employees have a way to communicate with each other.

Reason for choosing Amper

Amper was already in place when I started working here I just had to bring the process back on line and show the operators "why" it was important to