Aptean Process Manufacturing OEE

About Aptean Process Manufacturing OEE

Aptean Process Manufacturing OEE Pricing

Please contact Aptean for pricing details.

Starting price:

$30,000.00

Free trial:

Available

Free version:

Not Available

Most Helpful Reviews for Aptean Process Manufacturing OEE

3 Reviews

Kelly

Food & Beverages, 201-500 employees

Used weekly for more than 2 years

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

4

CUSTOMER SUPPORT

4

FUNCTIONALITY

4

Reviewed July 2017

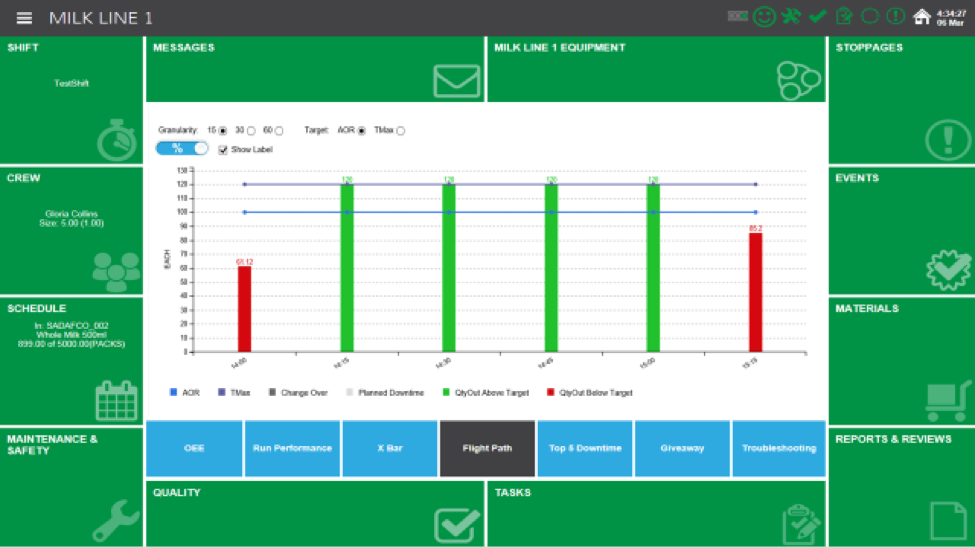

The user experience for our shop-floor employees is by far the greatest win here!

When we first looked at a system to support gathering performance metrics on our plant floor, we had a few different options; Factory MES was what I would call an "out of the box solution" that presented industry standards and supported the plant floor. If the plant floor was not going to engage in entering information and utilizing the system, we were not going to be able to deliver metrics to Management in the plant or at corporate. This system delivered a tool that engaged our Operators. We were not looking to build our own system with a SCADA-based solution, so this option fit our needs. We still struggle with the overwhelming amount of data that is being collected by FMES and how best to marry that up with other data. However, the Performance-based KPIs are there, easy to use, easy to drill into details, and are real-time to both the operator and to the supervisor in the plant and elsewhere in the company. If we were to have a "do-over", we would absolutely still select Factory MES as our tool of choice; but during implementation we would require more supervision to be part of the initial team. Their engagement, second to the Operator engagement, is key to driving results. We are getting there, more of an evolution though.

PROSThis is a powerful product that offers a user interface that not only offers flexibility for the end-user so that relevant information is shown for the appropriate area of the plant and/or user, it also is extremely user-friendly. The large buttons displayed and use of red/yellow/green makes it easy for our Supervisors to react to a potential obstacle (red/yellow) or a solid performance (green) in those areas. Aptean continues to evolve this product, looking for opportunities to better support the ever-changing manufacturing environments. This is another benefit to partnering with Aptean on this product. As our business evolves, we need the product to evolve and grow with us.

CONSIn the past, integration has not been as seamless as we would have wanted. This has improved and continues to improve.

Ryan

Food & Beverages, 201-500 employees

Used daily for more than 2 years

OVERALL RATING:

4

EASE OF USE

4

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed July 2017

Amazing ROI

This software implementation has been the single biggest success in my 15 years at the company. The ROI is undeniable. The opportunity for culture change is very big. It can really change the approach and focus of your manufacturing employees and management to look for and act on accurate actionable data. The outputs clearly show where your resources should be focused for efficiency gains. Its critical to postion the project correctly as a culture shift driven by and for manufacturing, not a mangment tool to flog manufacturing. That step is key to adoption and adoption is key to ROI.

PROSFast deployment. Fast Payback. SImple setup. Shop Floor focused operation and interface. Very graphical and intuitive

CONSNot so much a con, as a tip. You must spend the time and the resources to properly model your hierarchies and your events. Attention to these aspects during setup will have a big impact on the data you receive being actionable out of the gate. The user setup and report subscription are a bit convoluted and dated. But you don't have to deal with that often once you up and running. Out of the box the focus is on OEE, a mostly European concept. Some shops prefer the included unit / hour views that are more prevalent in the US.

Mark

Food & Beverages, 201-500 employees

Used daily for more than 2 years

OVERALL RATING:

4

EASE OF USE

4

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

3

Reviewed June 2019

Great tool

Factory is pretty easy to use for the operators and is improving with every version.

PROSFactory is very user friendly for the operators when using basic functions and it allows for customization to add ease and granularity of the downtime reasons

CONSConfiguration is a bit challenging requiring making changes in multiple locations for even simple tasks. Documentation of the more nuanced parts of the software is hard to locate and sometimes required reaching out to tech support for answers. Some of the fixes to bugs are listed as "fixed in next version" only to find out that isn't the case and "now it's fixed in next version"