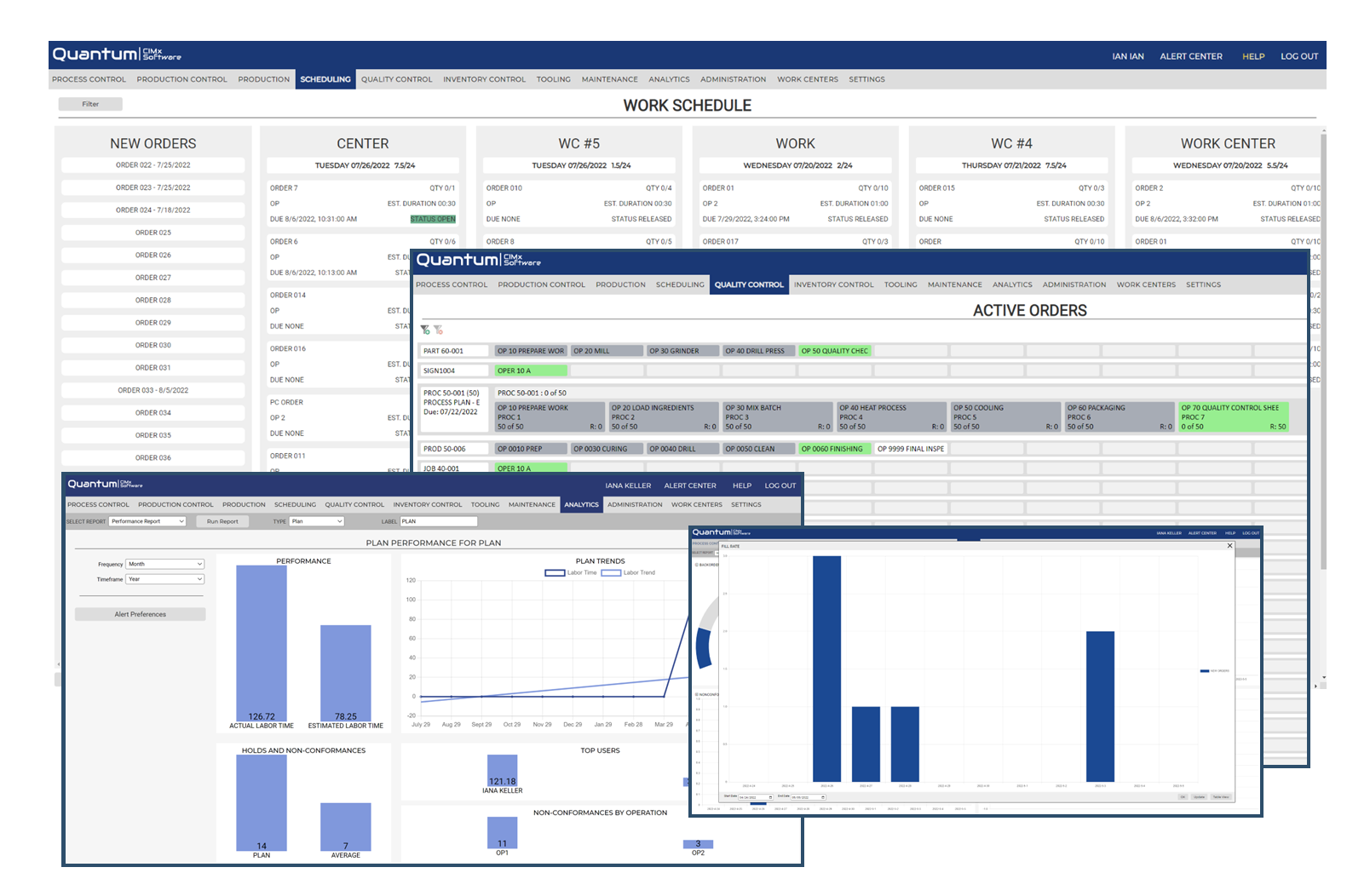

Quantum

About Quantum

Quantum Pricing

Contact CIMx for more details

Free trial:

Available

Free version:

Not Available

Other Top Recommended Manufacturing Software

Most Helpful Reviews for Quantum

1 - 5 of 5 Reviews

Jason

Furniture, 51-200 employees

Used daily for less than 2 years

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed September 2018

Game Changer

My over all experience with quantum has been great. It has helped our production team become more efficient.

PROSI am most impressed with Quantum's ability to be flexible with our production demands. We have custom screens for multiple areas. CimX has been great at allowing us to change and add features to all those screens. Quantum has allowed us to track problems, trends, exc... with ease. By using Quantum in our daily processes we have saved money and hours on research and defects. Quantum allows us to identify and focus in on our biggest problems. The company I work for has never had any software with this level of detail in tracking.

CONSI have had to create my own reports by using different software. It is not friendly to those of us that do not have programming experience. It would be extremely helpful if Quantum could design a program to go with the product they already have. Quantum track everything you want it to so there should be an easy way pull the information. If it wasn't for my own employee's knowledge in programming, Quantum would be useless in getting reports.

edgar

Used daily for less than 2 years

OVERALL RATING:

4

EASE OF USE

5

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed January 2018

easy to use and manage, more than anything, it's easy to understand. very visual

PAPERLES

PROSthat this software register every action that the user did. this is very helpful at the moment that the company has an audit and personal.

CONSthat the software is not compatible with a proper hardware. it's not the same running it the software in a computer than running it in a tablet. but I know that also this is depend of the qualities that my hardware has.

Vendor Response

Thank you so much for your review of our Quantum Production Control System. Your comments support in the evolution of our future product features. We would be happy to work with your team in the future to ensure that any selected hardware meets the necessary requirements and supports in the optimization of Quantum's performance and your production.

Replied January 2018

Alexis

Electrical/Electronic Manufacturing, 51-200 employees

Used daily for less than 2 years

OVERALL RATING:

3

EASE OF USE

4

FUNCTIONALITY

3

Reviewed February 2018

it has been a good experience, some new with very benefits

The software is practical and easy to use once learned

PROSI like the idea of take care of the earth, paperless and all the other benefits for our company and others

CONS1. The quality of the drawings. For some reason when we add drawings at the work centers, the high quality of drawings becomes poor, lines, dimensions, tolerances, does not read well, in some of cases it's necessary to see the original drawing (pdf) The quality in drawings it's critical, for the quality of our products and better service for our costumers, the inspector take decisions all the time based in the specifications in drawing, when the drawing is not clear because of poor quality of drawings in CIMx screen, we have to take action and verify this issue, and this it's a lost time, I was talking this with P. Torres Q.C. Manager and we both have the same opinion 2. DEFECTS Report We cannot see an report where we have all the concentrated defects and shop orders by part number, if we want to analyse defects we have to search in another software the shop orders of some part number that we sent and after that, search order by order in CIMx software and check the defects, this take some time, for example: if the part number is continuous, several orders by month and we had to verify the defects from 6 months ago more or less

Vendor Response

Thank you so much for the in depth review of Quantum. The team at CIMx would be happy to make recommendations of resolutions of images and diagrams to ensure they are optimal for display. You can reach out to support@cimx.com at any time. In addition, we can certainly work with your team to create any reports that are not inherently in the system. Since every business will have unique needs, and often those needs are uncovered after new system evolves your process, we will work with your team to ensure you have all the necessary tools to be successful. UPDATE (2/27/2018): Based on your review and feedback, we were able to update the standard product to accommodate for your drawing and instruction resolution. This, among other updated features, will be available to all Quantum customers in the newest release of the product.

Replied February 2018

Jesus

Used daily for less than 12 months

OVERALL RATING:

4

EASE OF USE

4

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed January 2018

Very helpful software, you can use it everywhere.

On my opinion, you can access and modify the information very easy. Also we can upload PDF files for been opened.

CONSIt is very important to have the correct information on all the Pop Up messages. sometimes it is a bad language translation or misunderstood.

Vendor Response

Thank you so much for your review. Your insight helps to shape the future features and functionality of our Quantum Production Control System. When first implemented, translations are provided to the team, but as production expands, there may be a need to update or revisit additional translations. As you come across any translation gaps, simply send an email list to support@cimx.com and we will be happy to get those updated.

Replied February 2018

Pablo Torres

Used daily for less than 6 months

OVERALL RATING:

3

EASE OF USE

3

VALUE FOR MONEY

3

CUSTOMER SUPPORT

4

FUNCTIONALITY

3

Reviewed January 2018

It is easy to use but I think you have not described being able to use the whole screen.

It is easy to use but missing the whole screen would help us in inspection and testing. We have been able to link with other programs. We need to be able to see-print defect reports.

CONSThe area where the information is shown as drawings, process sheets, etc. is small, I would like to see it on the whole screen

Vendor Response

Thank you for your review. We take pride in our support structure and can certainly show you how to adjust your operator view to better accommodate your needs. You can always reach us at support@cimx.com and we will be happy to walk you through any features you need additional insight or training that you need.

Replied January 2018