TrakSYS

About TrakSYS

TrakSYS Pricing

TrakSYS platform pricing is based on activated features and functions.

Starting price:

$6,500.00 one time

Free trial:

Available

Free version:

Available

Other Top Recommended Manufacturing Software

Most Helpful Reviews for TrakSYS

1 - 5 of 39 Reviews

Matt

Verified reviewer

Food Production, 201-500 employees

Used daily for less than 12 months

OVERALL RATING:

5

EASE OF USE

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed March 2018

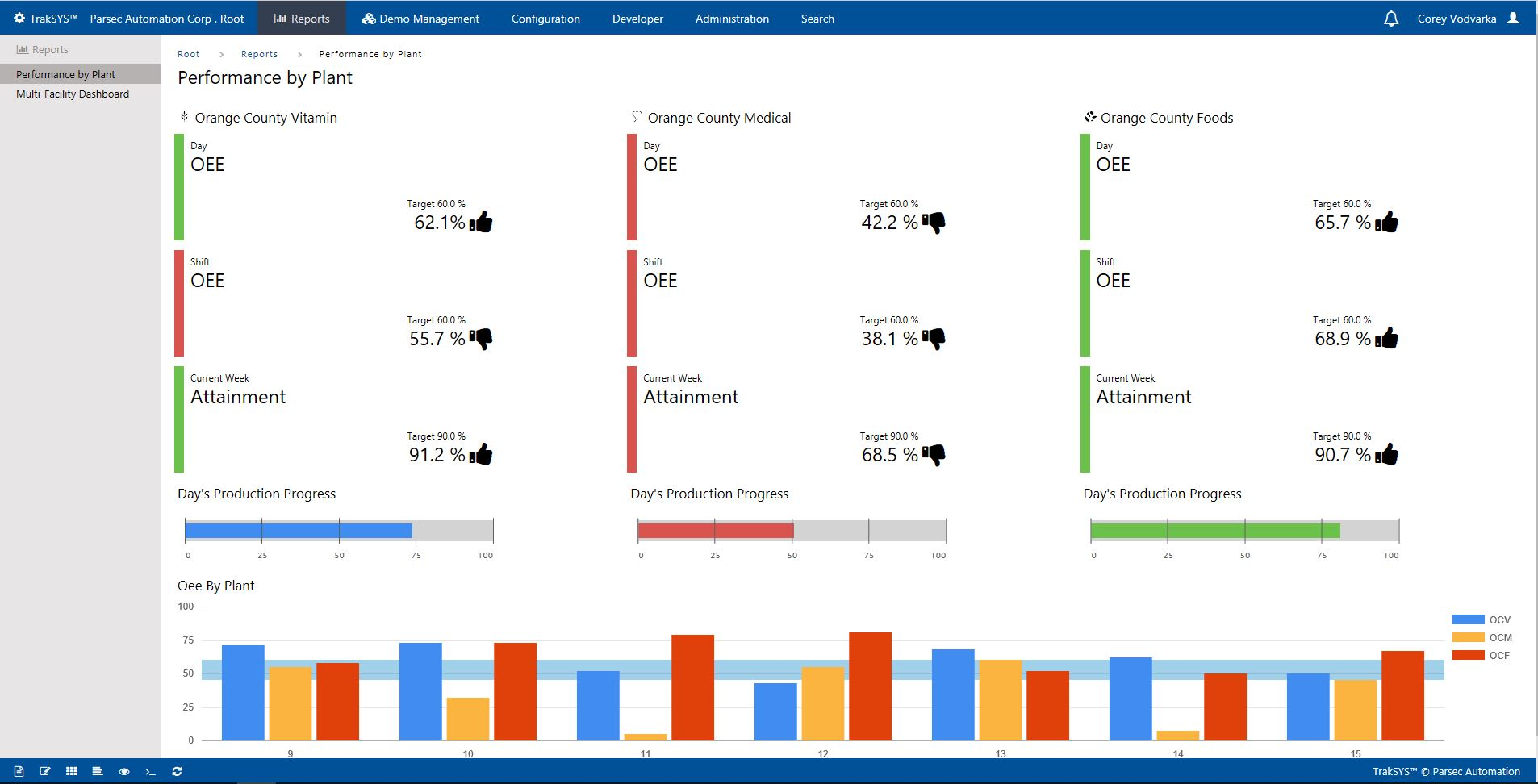

Great OEE solution

We get detailed and accurate information about our equipment operation, downtime, and plant trends. It helps make business decisions and focus improvement teams.

PROSWe use this as an OEE solution on plant production lines. We have large screens on the wall with dashboard information carrying real time info. It's fairly easy to use once configured. It's not going to improve OEE for you unless you use the data to manage your process. It's important that many people know what the data is, where it comes from, what it means. It's even more important that a few key users dig into the data on a regular basis to identify trends and opportunities in the business.

CONSNot much to dislike. When configured well, the only thing to dislike is the lack of time available to explore the data it presents about your operation.

José Francisco

Verified reviewer

11-50 employees

Used daily for more than 2 years

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

5

Reviewed March 2018

TrakSYS is a powerful MOM software

With the use of TrakSYS I have increased my knowledge of manufacturing processes, in addition to achieving satisfied customers because they speed up and reduce their tasks, effort and improve the decision making opportunities or tying problems that arise in your company and all thanks to the use of TrakSYS in their companies.

PROSit is capable of being a highly vital tool because its agility and configurability can be adapted to any manufacturing sector and provide important KPIs, is able to adapt to many web browsers and also with a very good translation system. The software is well structured, it also has a very secure process for updating project configurations.

CONSit lacks an embedded tool to prepare PDF reports, a dashboard printing functionality, and increase the catalog of graphics, such as Radar, Radial and Gauss type.

Keith

Electrical/Electronic Manufacturing, 51-200 employees

Used daily for less than 2 years

OVERALL RATING:

3

EASE OF USE

4

VALUE FOR MONEY

5

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed April 2018

Great rapid prototyping. Much nicer to use with improved documentation.

Fast and easy to use.

PROSGreat to have a solid API for large data entry. The database and configuration utilities are the main strength of this application.

CONSWeb interface is slow. It could use a lot of improvement to keep more operations client side. We know that after making certain changes, the logic service must be restarted. Why not automatically detect and prompt to restart? To maintain the option 'not now' might be necessary. Possibly some sort of dirty flag to visually indicate that the logic service needed to be restarted. OPC-UA support should be a great improvement over current OPC support.

Juan

Verified reviewer

11-50 employees

Used daily for more than 2 years

OVERALL RATING:

5

EASE OF USE

5

VALUE FOR MONEY

4

CUSTOMER SUPPORT

5

FUNCTIONALITY

4

Reviewed April 2018

my work experience in several industries has been important for my development

That I have learned a lot and from several manufacturing issues since it is required for specific developments such as downtime and spc.

PROSthat can be developed by modules or a complete integration that is easy to use and connect with data communication devices and connection with external systems, has flexibility for developments in different companies.

CONSthat sometimes does not allow to add styles in the designs made for exclusive plants and that there are parts that do not allow to add configurations required by the company in which it is developing as are the graphics and that sometimes does not take the colors correctly .

Rob

Food Production, 10,000+ employees

Used daily for more than 2 years

OVERALL RATING:

4

EASE OF USE

4

VALUE FOR MONEY

3

CUSTOMER SUPPORT

4

FUNCTIONALITY

3

Reviewed March 2018

Very nice product, quite complete. Good company

Visibility on, and insight in, the performance of our production lines, in context to product, order, formula, cost

PROSI especially like the graphical user interface of the product. It is very powerful and does not require any compilation to deploy.

CONSI believe the product would benefit from a good BPMN engine to configure and execute workflows within the product. This would transform the product into a real complete MES solution.