The 15 Questions About MES Requirements Every Manufacturer Should Ask

The details are important when communicating your needs to a manufacturing execution system (MES) provider, and without the right questions, it’s far too easy to end up with an investment that doesn’t deliver.

In fact, more than a third of MES deployments failed to address a majority of the intended business goals, according to a 2017 Gartner survey. This highlights a disconnect between the software vendor’s functional capabilities and the manufacturer’s ability to fully and accurately explain their needs.

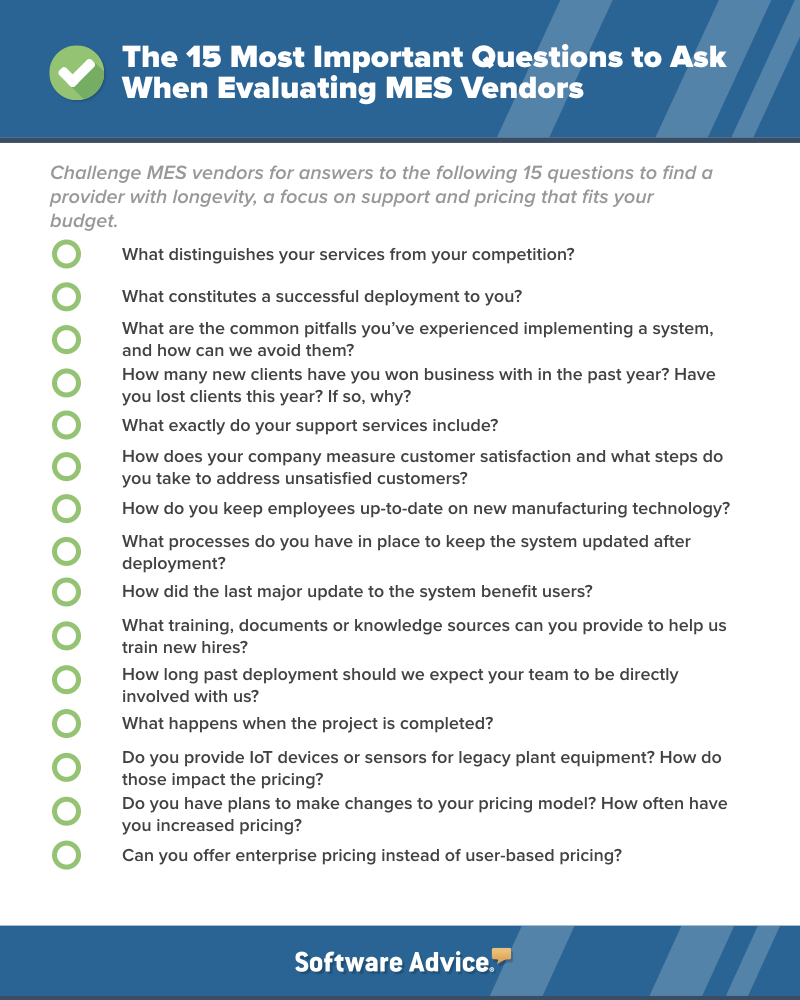

Armed with the 15 most important questions about the vendor, system life cycle and pricing, manufacturers are much more likely to adopt a system that increases production efficiency and reduces costs.

Below, we’ve listed questions to ask about each of those three areas and why they matter.

Questions to Ask About the Vendor

What distinguishes your services from your competition?

What constitutes a successful deployment to you?

What are the common pitfalls you’ve experienced implementing a system, and how can we avoid them?

How many clients have you gained in the last year? Have you lost any clients this year? If so, why?

What exactly do your support services include?

How do you measure customer satisfaction and what steps do you take to address unsatisfied customers?

When your company invests in software, you’re also investing in the vendor themselves. You should expect the vendor to step in and help solve problems when they occur.

It can be difficult to determine the vendor’s level of capability in this area, but they should be willing to answer these tough questions to win your business.

These questions cut to the most critical factor in your long-term MES success. Plenty of vendors can produce an application to help manage manufacturing, but the commitment and ability to assist a client when issues arise is what makes a software provider a strong partner.

TAKEAWAY: Use these six questions to understand and define the vendor/client relationship, including how to escalate problems, communication channels, training resources and timelines.

Questions to Ask About the System Life Cycle

How do you keep employees up-to-date on new manufacturing technology?

What processes do you have in place to keep the system updated after deployment?

How did the last major update to the system benefit users?

What training, documents or knowledge sources can you provide to help us train new hires?

How long past deployment should we expect your team to be directly involved with us?

What happens when the project is completed?

“Legacy software” sounds nice, but it’s actually just a euphemism for software that is outdated and unsupported. Today, most companies are moving toward cloud-based software, with frequent updates that minimally interfere with production.

These questions are designed to find out how the vendor can deliver benefits that keep your system, users and training updated. Vendors need to stay on top of technology and innovation trends in the industry, so it’s important to ask vendors how they facilitate learning to remain competitive.

Vendor support throughout the system’s life cycle includes several things:

Providing resources to help users become more proficient and train other employees.

The cadence of updates and how those updates are rolled out.

Serving as thought leaders with a blog or video content that shares news about the industry with clients.

TAKEAWAY: Use these six questions to gauge a vendor’s capability and commitment to long-term support after deployment, and how these services can help you reach your manufacturing goals.

Questions to Ask About the Pricing

Do you provide internet of things devices or sensors for legacy plant equipment? How do those impact pricing?

Do you have plans to make changes to your pricing model? How often have you increased pricing?

Can you offer enterprise pricing instead of user-based pricing?

Pricing information tends to be one of the last conversation topics before making a software purchase, and various add-ons can impact the cost. When you’re making an investment of this size, these questions help you get the most functionality for your money and a sense for how often pricing can change.

A few things that will likely impact your total cost of ownership include:

Additional modules for more features

Software-as-a-Service (SaaS) model or traditional on-premise deployment

Unexpected pricing changes

Training and support services

More and more industries are adopting internet of things (IoT) technology to enable communication between machines and data streaming, which gives managers an unparalleled view into the health and performance of production assets.

IoT devices that can even connect older machines to a network are increasingly inexpensive, and many vendors provide them. Determine whether an IoT approach is part of your long-term strategy before evaluating vendors.

Also, challenge the vendor to offer enterprise instead of user-based pricing—if you hope to scale your business over time, user-based pricing can make growth expensive as you need increasingly more people to use the system.

TAKEAWAY: Use these three questions to avoid surprises in pricing, and to understand your preferred vendor’s pricing structure and any hidden costs that aren’t already clearly laid out.

I’m Ready to Begin My Search! What’s Next?

Great! Here are some next actions you can take to get started on the right foot:

Check out descriptions and real user reviews for the top MES products.

Call us at (855) 998-8505 for a free software consultation with our advisors to narrow down the list of vendors that can address your particular needs.

Download our checklist to keep on hand during the evaluation. These 15 questions will help guide your search to find the best MES vendor.