Find the best Manufacturing Execution Systems

Compare Products

Showing 1 - 20 of 209 products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Sponsored: Sorts listings by software vendors running active bidding campaigns, from the highest to lowest bid. Vendors who have paid for placement have a ‘Visit Website’ button, whereas unpaid vendors have a ‘Learn More’ button.

Avg Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

A to Z: Sorts listings by product name from A to Z.

NetSuite

NetSuite

FrontRunners 2024

With an integrated system that includes ERP, financials, commerce, inventory management, HR, PSA, supply chain management, CRM and more – NetSuite enables fast-growing businesses across all industries to work more effectively by a...Read more about NetSuite

Fishbowl

Fishbowl

FrontRunners 2024

Fishbowl is the #1 manufacturing and warehouse inventory management software! Its powerful inventory control system gives your small or midsize business the exact tools needed to transform your inventory management and scale your ...Read more about Fishbowl

Tangle

Tangle

Tangle is an open-source, low-code development solution that enables organizations to construct, design, and deploy enterprise-level applications. The platform provides various reusable components such as charts, tables, boards or...Read more about Tangle

QT9 ERP

QT9 ERP

QT9 ERP is a highly-scalable manufacturing platform for connecting and automating business data from multiple systems into one scalable and intuitive solution. QT9 ERP integrates inventory management, accounting management, sales ...Read more about QT9 ERP

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Meet Eric, a software expert who has helped 1,534 companies select the right product for their needs.

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Tell us more about your business and an advisor will reach out with a list of software recommendations customized for your specific needs.

STEP 1 OF 4

How many employees are in your company?

REALTRAC

REALTRAC

Realtrac is an on-premise job management solution designed for job shop manufacturers and modular machine shops. It helps small and midsize manufacturers to schedule workflows, manage shop operations, track inventories, manage pur...Read more about REALTRAC

Visual EstiTrack

Visual EstiTrack

Henning Software has helped small to midsize manufacturers and job shops for 30 years. Visual EstiTrack ERP has complete material requirements planning, product lifecycle, supply chain, customer relationship, human resource and ma...Read more about Visual EstiTrack

Mar-Kov Chemical Management System

Mar-Kov Chemical Management System

Mar-Kov CMS (Chemical Management System) is a cloud-based process manufacturing solution for process, batch, and formulation based manufacturers. The solution can also be installed on-premise to automate daily routine processes of...Read more about Mar-Kov Chemical Management System

DELMIAworks

DELMIAworks

DELMIAworks (formerly IQMS) ERP is developed specifically for SMB and large discrete and batch process manufacturers in the aerospace, medical device, automotive, food and beverage, consumer products, plastics, packaging, and elec...Read more about DELMIAworks

Rootstock Manufacturing ERP

Rootstock Manufacturing ERP

Rootstock Software is a global provider of manufacturing cloud ERP on the next generation Salesforce Platform. It is purpose-built for mid-size discrete manufacturers who are looking to digitally transform on a future-proof platfo...Read more about Rootstock Manufacturing ERP

ION

ION

ION by First Resonance accelerates manufacturing for companies building mission-critical applications in hardware. ION reliably move parts, workflows, and data through manufacturing while ensuring accurate data capture at each jun...Read more about ION

V5 Traceability

V5 Traceability

V5 Traceability is a food traceability and inventory control solution that helps businesses of all sizes in the food and beverage, pharmaceuticals, and manufacturing industries. The MES system helps users streamline manufacturin...Read more about V5 Traceability

ShopKeeper Job Control

ShopKeeper Job Control

ShopKeeper Job Control is the flagship of the application suite that makes up the ShopKeeper ERP shop management solution for small- to mid-sized job shops, process shops and contract manufacturers. This solution has been refined ...Read more about ShopKeeper Job Control

SAP S/4HANA Cloud

SAP S/4HANA Cloud

SAP S/4HANA Cloud is a cloud-based and on-premise enterprise resource planning (ERP) solution. It is suitable for small, midsize and large businesses in industries such as automotive, engineering, construction, mining, research an...Read more about SAP S/4HANA Cloud

ALERE

ALERE

ALERE ERP, brought to you by TIW Technology, is a robust, modular manufacturing package that offers accounting, manufacturing, inventory management, CRM, service, analytics, document management, and data acquisition. Designed for ...Read more about ALERE

FactoryLogix MES

FactoryLogix MES

FactoryLogix is a manufacturing solution suitable for businesses of all sizes. Key features include manufacturing execution, quality management, product lifecycle management, supply chain management, supplier management, asset man...Read more about FactoryLogix MES

ProfitKey

ProfitKey

ProfitKey is an on-premise manufacturing management solution for small and midsize manufacturers and job shops. It caters to various manufacturing industries including aerospace, defence, automotive, capital equipment, electronics...Read more about ProfitKey

MasterControl Quality Excellence

MasterControl Quality Excellence

MasterControl is the #1 QMS in the life sciences with more life sciences customers than any other QMS provider. For over 30 years, we’ve helped companies of all sizes bring their life-changing products to market sooner. We provide...Read more about MasterControl Quality Excellence

Deltek Costpoint

Deltek Costpoint

Deltek Costpoint is an enterprise resource planning (ERP) and management solution designed to meet the requirements of midsize and large enterprise businesses. The solution primarily assists government contractors, professional se...Read more about Deltek Costpoint

MRPeasy

MRPeasy

FrontRunners 2024

MRPeasy is a versatile cloud-based ERP system for small and scaling companies (perfect for up to 200 employees). The software offers a complete ERP solution with robust production planning and inventory management functionalities ...Read more about MRPeasy

Fulcrum

Fulcrum

Fulcrum is a cloud-based platform serving small/mid-sized manufacturers and job shops looking for a software platform that truly understands them and their unique, complicated processes. Humans weren’t meant to transcribe data fro...Read more about Fulcrum

Buyers Guide

Last Updated: March 16, 2023Manufacturing execution systems (MES) manage operations on the shop floors of factories. Some MES support a single class of machine; others are designed to oversee operations on the entire floor. We wrote this buyer's guide to explain MES technologies and assist buyers in making a selection.

Here’s what we’ll cover:

What Is MES Software?

“If you build it, they will come,” is not a quote about manufacturing, but the concept is related. MES software manages operations on the shop floor. The scope of MES can vary from scheduling a small set of critical machines to managing the entire fabricating operation for a manufacturer. In all but a handful of cases currently, the MES does not directly control a machine but rather tracks the work-in-progress on the shop floor.

MES is a subset of enterprise resource planning (ERP) systems and executes the plan determined by the manufacturing resource planning (MRP) system. The functions of MES programs include: compiling a bill of materials, resource management and scheduling, preparing and dispatching production orders, preparing work-in-progress (WIP) reports and tracking production lots. Advanced systems will also have a product definition library with revision history and can report on production status to an ERP. In contrast, an MRP system sets the production schedule, determines the make versus buy list and determines inventory requirements.

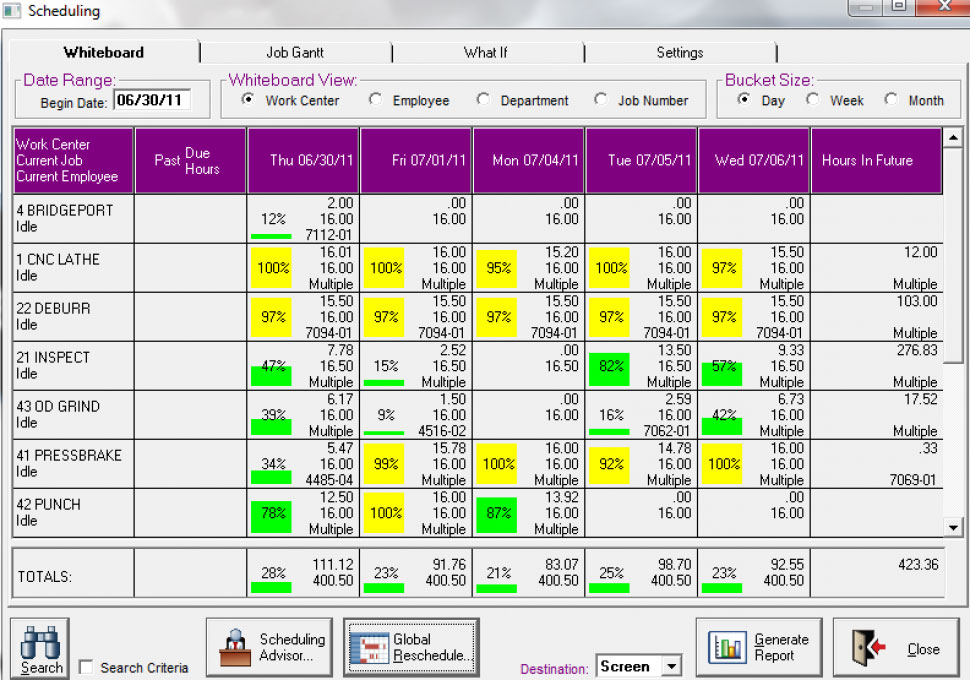

Screenshot of E2 Shop System scheduling whiteboard

The MES is responsible for scheduling and tracking each step of the production phase of a particular job. It prints out the bill of materials that the operator will require and production steps to complete at each phase. It repeats this process for each operator and each step until a particular job is complete.

MES is not generally effected by a manufacturer's mode, be it make to stock (MTS), assemble to stock (ATS), assemble to order (ATO), make to order (MTO) or engineer to order (ETO). This is because by the time the MES is invoked, the parts and schedule are already set, usually by the MRP system.

MESes are generally installed on-premises, but cloud-based solutions are becoming available. In most businesses, one of the reasons for having a cloud-based system is the reduced initial cost for equipment. This is not necessarily true for manufacturing; if the system has just a few users then they are usually located in the same facility and it is just as easy to link them to each other as it is to give them access to the Internet. If it is a large implementation, the expense is in creating a robust network and acquiring suitable fixed and mobile workstations. The incremental cost difference between having a server for the software is generally minimal. Instead, the benefit of cloud-based systems is the reduced cost for system management; the servers are out of the shop floor environment, can be backed-up and replicated automatically, and do not have to be maintained by trained on-site personnel.

What Type of Buyer Are You?

The first step in evaluating MES software is to determine what type of buyer you are. Over 90 percent of software buyers fall into one of these three groups:

Enterprise resource planning suite buyer. These buyers value the seamless integration of data and processes that comes from having one system for all functions. For example, they would prefer a full-suite system for estimating, work-in-progress management and accounting that can automatically turn an estimate into a budget for project management and then match invoices to project status and allocate job costs. These buyers favor complete software suites from companies like Oracle, SAP, Sage ERP or Microsoft Dynamics.

Departmental buyer. Specialists in one function, such as creating process set points, may value the feature depth of best-of-breed solutions designed for their function. These buyers may need specific functionality, like the ability to interface with a specific computer motion control system.

Small manufacturer. Small organizations often have limited budgets and fewer IT resources and tools to dedicate to software. In many cases, they may be deciding between a new software system and a new piece of equipment. These buyers need cost-effective SMB manufacturing solutions that are easy to implement and use. Some will prefer full-suite systems, while others may just want one application, such as bill-of-materials production or shop equipment scheduling operations.

Benefits and Potential Issues

Increase utilization of equipment: MES systems let manufacturers measure the actual utilization of equipment. With this knowledge, you can adjust job prices to either encourage the use of certain equipment or dissuade the use of that equipment.

Better record-keeping and data analysis: MES provides records not of machine use, jobs and lots. This yields several benefits. First, there is better tracking of actual materials used, increasing accountability of material use to individual operators, which generally reduces waste. Second, should a quality problem occur, lot tracking allows tying back the issue to the individual lots instead of having to potentially recall an entire run.

Real-time WIP reporting: MES systems can report on progress on jobs and lots in real-time, giving shop managers better information and allowing for modifications to the schedule to adjust for changes in productivity.

One of the big issues with implementing MES is the possibility it will be rejected by the shop floor personnel. Some workers find the method and amount of information collected intrusive. This can become a contract issue in a unionized shop. The best defense is to use a phased-in implementation coupled with training that emphasizes the benefits to workers.

Market Trends to Understand

Increased use of electronic documentation. Not so long ago, a shop floor had stacks and stacks of operator’s manuals, procedure manuals and material safety data sheets. Operators had clipboards and notebooks with bills of materials, work orders and reports. More and more, however, this paper is being replaced with electronic documents. MES documentation is no exception, most users produce electronic work orders and schedules.

Mobile devices used for reference and control. Related to the increased use of electronic documentation is the use of mobile devices on the shop floor. The days of using clipboards and paper kanban cards are quickly coming to an end. Instead, workers are using tablet computers and handheld devices to enter information directly into the MES system.

Increased integration with enterprise systems. Considering that ERP grew out of MRP and MES systems, it is no surprise that the integration with other systems is a continuing trend. Even stand-alone MES systems can receive data from MRP systems and inventory systems, and send information to others, like preventive maintenance systems (which track the hours that equipment has been used) and payroll systems (which track how much time workers spent on each job).

Machine integration. MES systems can now integrate directly with computer-controlled shop-floor machines, downloading directions and recipes when required.

Data consolidation and visualization. MES systems can collect and consolidate information from the various production systems. Production dashboards are beginning to make their appearance in systems, giving production managers a single view to track operations in real time.

The MES Vendor Landscape

This type of buyer... | Should evaluate these systems |

Enterprise resource planning suite buyer | Microsoft Dynamics, Oracle, SAP, Sage |

Departmental buyer | Microsoft Dynamics, Epicor, SYSPRO, Casco |

Small manufacturer | E-Z-MRP, ECi, Exact, Fishbowl |