Find the best Capacity Planning Software

Compare Products

Showing 1 - 20 of 240 products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Sponsored: Sorts listings by software vendors running active bidding campaigns, from the highest to lowest bid. Vendors who have paid for placement have a ‘Visit Website’ button, whereas unpaid vendors have a ‘Learn More’ button.

Avg Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

A to Z: Sorts listings by product name from A to Z.

NetSuite

NetSuite

With an integrated system that includes ERP, financials, commerce, inventory management, HR, PSA, supply chain management, CRM and more – NetSuite enables fast-growing businesses across all industries to work more effectively by a...Read more about NetSuite

Fishbowl

Fishbowl

Fishbowl is the #1 manufacturing and warehouse inventory management software! Its powerful inventory control system gives your small or midsize business the exact tools needed to transform your inventory management and scale your ...Read more about Fishbowl

Global Shop Solutions

Global Shop Solutions

Global Shop Solutions offers ERP software to serve clients across manufacturing industries of all sizes. The multi-modular application is comprised of independent modules for customer relationship management, inventory management,...Read more about Global Shop Solutions

Deskera MRP

Deskera MRP

Deskera enables fast growing businesses to operate more efficiently by providing them with an integrated platform that connects manufacturing, accounting, erp, inventory and warehouse management, order fulfillment, procurement, sa...Read more about Deskera MRP

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Meet Eric, a software expert who has helped 1,534 companies select the right product for their needs.

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Tell us more about your business and an advisor will reach out with a list of software recommendations customized for your specific needs.

STEP 1 OF 4

How many employees are in your company?

QT9 ERP

QT9 ERP

QT9 ERP is a highly-scalable manufacturing platform for connecting and automating business data from multiple systems into one scalable and intuitive solution. QT9 ERP integrates inventory management, accounting management, sales ...Read more about QT9 ERP

Mar-Kov Chemical Management System

Mar-Kov Chemical Management System

Mar-Kov CMS (Chemical Management System) is a cloud-based process manufacturing solution for process, batch, and formulation based manufacturers. The solution can also be installed on-premise to automate daily routine processes of...Read more about Mar-Kov Chemical Management System

Aquilon ERP

Aquilon ERP

Aquilon Software offers a combined supply chain, manufacturing, distribution, and financial management system that is deployable either on the cloud or on-premise. All modules integrate with each other, allowing users to gain full...Read more about Aquilon ERP

Rootstock Manufacturing ERP

Rootstock Manufacturing ERP

Rootstock Software is a global provider of manufacturing cloud ERP on the next generation Salesforce Platform. It is purpose-built for mid-size discrete manufacturers who are looking to digitally transform on a future-proof platfo...Read more about Rootstock Manufacturing ERP

R4 Enterprise

R4 Enterprise

Royal 4 Enterprise is an integrated enterprise resource planning (ERP) solution with built-in modules for distribution, manufacturing, planning, inventory management, reporting and company financials. It serves midsize to large en...Read more about R4 Enterprise

ION

ION

ION by First Resonance accelerates manufacturing for companies building mission-critical applications in hardware. ION reliably move parts, workflows, and data through manufacturing while ensuring accurate data capture at each jun...Read more about ION

Propel

Propel

Propel Software helps product companies grow revenue and increase business value with PLM, QMS, PIM, and supplier management on a single cloud platform. Our product value management solution connects commercial and product teams t...Read more about Propel

Metasystems

Metasystems

ICIM ERP by Metasystems offers small and midsize discrete manufacturers a comprehensive ERP that brings together order management, engineering, manufacturing, CRM, financials and warranty management. It supports the business needs...Read more about Metasystems

Connected

Connected

Connected is a hybrid integrated accounting and enterprise resource planning (ERP) that caters to small and midsize businesses across various industry verticals and helps them to integrate their data and processes across departmen...Read more about Connected

OptiProERP with Sap Business One

OptiProERP with Sap Business One

OptiProERP with SAP Business One is a complete ERP solution for small and midsize manufacturers and distributors. SAP Business One is an ERP platform designed for small and midsize companies with over 70,000 customers. OptiProERP ...Read more about OptiProERP with Sap Business One

Datacor ERP

Datacor ERP

Datacor ERP (formerly Chempax) is an integrated enterprise resource planning (ERP) and customer relationship management (CRM) application designed specifically for chemical process manufacturers and distributors. The solution can ...Read more about Datacor ERP

BatchMaster ERP

BatchMaster ERP

BatchMaster Software offers process manufacturing software solutions for the food, chemical, nutraceutical and pharmaceutical industries. Users can run the manufacturing application with QuickBooks, Sage 100&300, Microsoft Dynamic...Read more about BatchMaster ERP

SAP S/4HANA Cloud

SAP S/4HANA Cloud

SAP S/4HANA Cloud is a cloud-based and on-premise enterprise resource planning (ERP) solution. It is suitable for small, midsize and large businesses in industries such as automotive, engineering, construction, mining, research an...Read more about SAP S/4HANA Cloud

ProfitKey

ProfitKey

ProfitKey is an on-premise manufacturing management solution for small and midsize manufacturers and job shops. It caters to various manufacturing industries including aerospace, defence, automotive, capital equipment, electronics...Read more about ProfitKey

Deltek Costpoint

Deltek Costpoint

Deltek Costpoint is an enterprise resource planning (ERP) and management solution designed to meet the requirements of midsize and large enterprise businesses. The solution primarily assists government contractors, professional se...Read more about Deltek Costpoint

MRPeasy

MRPeasy

MRPeasy is a versatile cloud-based ERP system for small and scaling companies (perfect for up to 200 employees). The software offers a complete ERP solution with robust production planning and inventory management functionalities ...Read more about MRPeasy

Popular Comparisons

Buyers Guide

Last Updated: March 16, 2023A wide variety of businesses must grapple with capacity management. Leaders can't simply drop a massive workload on employees and expect to meet a deadline without considering dozens of factors.

In manufacturing production, labor hours, raw materials, tools and equipment, storage and other resources must be carefully assessed before work even begins. All of these moving parts make up capacity—a critical element for production efficiency.

Software can assist companies in applying the complex algorithms to disparate aspects of production operations to meet demand seamlessly. This buyer's guide is designed to help you learn more about the capabilities of capacity planning systems.

We'll cover:

What Is Capacity Planning and Management Software?

Common Functionality of Capacity Planning and Management Software

Benefits of Capacity Planning and Management Software

What Is Capacity Planning and Management Software?

In the most basic terms, capacity planning systems help companies compare production loads with available capacity within a specific time frame. The process of planning for capacity helps avoid bottlenecks in production, which can impact the entire supply chain.

With data about required materials, equipment availability and man hours and costs, the software is able to spread out production needs across available machine capacity in order to meet demand, on time.

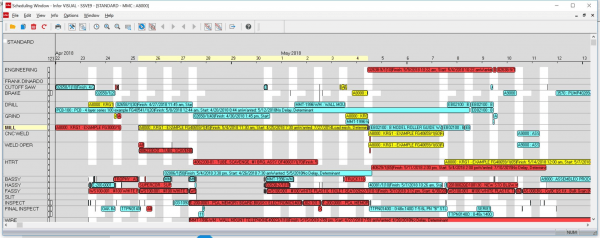

Capacity planning in Infor Visual ERP

There are some important terms related to capacity planning:

Infinite vs. finite capacity planning. These are the foundational concepts of capacity planning—infinite capacity assumes no limits on resources needed to produce enough units to meet demand. However, finite capacity factors in the constraints involved in real-world production situations.

For example, planners may know that a particular machine on a production line is only available for a maximum of, say, 10 hours during a normal shift. This is one kind of limitation that impacts capacity planning.

Thus, capacity planning software helps by scheduling around real-time constraints and other conditions that can impact production, instead of simply planning based on a baseline capacity level.

Production load leveling. Demand isn't always constant for manufacturers. In the case of fluctuating demand, it's necessary to maintain a smooth production workflow, which may include shifting capacity to "level" production across a few days instead of packing it all into one, or by expanding capacity by adding extra shifts or utilizing external capacity to meet demand (by using another manufacturing plant, for example).

Common Functionality of Capacity Planning and Management Software

These systems only have a few individual components, but each one provides useful insights about how to arrange your available capacity to meet production goals. These features often include:

Calendar production view | As orders come in, the system can place work into a schedule, and planners can view and edit schedules by dragging and dropping items on a calendar-style workflow chart. Users can also set priority levels for work orders and assign the total capacity available each day. |

Finite capacity management | As mentioned above, this functionality allows the system to factor in other planned work schedules, inventory, man hours, material levels and other factors to optimize production plans. |

Real-time capacity planning | Users can make on-the-fly changes to work order schedules or priorities if problems occur during production, instead of resetting the entire plan. |

Scenario testing and modeling | Capacity planning tools can help users test unfavorable supply chain scenarios by entering various values to optimize contingency plans. |

Reporting | As a system is used over time, it collects loads of valuable data. Reporting tools can arrange and visualize that data so managers can identify trends in production and address issues. |

What Type of Buyer Are You?

Any software purchase comes with several considerations and questions to ask. Identifying the type of buyer you are helps answer many of those. Below are some of the most common buyer types:

ERP suite buyer. Enterprise resource planning systems (ERPs) are complex platforms to assist manufacturers (and a wide variety of other types of businesses) by integrating data from all departments to gain a holistic view of operations. This software takes into account the many seemingly unrelated factors that can impact production schedules.

Many modern ERP systems offer capacity planning functionality, and use the wealth of collected data to predict potential issues in production that could impact capacity decisions.

MES buyer. Similarly, stand-alone manufacturing execution systems (MESs) typically offer a capacity planning component. Where an ERP gathers and analyzes information about an entire organization, an MES is hyper specific to that company's manufacturing process—maintaining production assets, dispatching production plans and improving quality of the finished product.

Since this type of software is so particular to the manufacturing type, it's often purchased by itself to integrate with an existing ERP. If you're buying an MES, you likely have the capacity planning functionality you need.

Make-to-order manufacturer. These types of companies begin production only after receiving a work order, so capacity planning is more crucial for these organizations than for those that continuously produce units.

In these situations, manufacturers have a short window to plan for capacity, but software can assist with leveling the load and factoring in other available resources necessary to meet production deadlines.

Benefits of Capacity Planning and Management Software

We've talked about the key benefit of automating the complex issue of capacity planning, but the software also offers some complementary benefits:

Optimize the use of assets. Especially for manufacturing plants with a variety of asset types, or different versions of the same type of asset, a capacity planning system can help prioritize jobs. This can lower production costs by shifting jobs to equipment that is less expensive to operate depending on the type and time frame of manufacturing.

Spot production bottlenecks. During capacity planning, the software can help identify specific assets or processes causing slowdowns or inefficiencies. The system's recommendations for prioritizing or spreading out work may reveal these bottlenecks.

Boost the useful life of assets. Because capacity planning helps level the workload, the tasks aren't placed solely on one or two machines, so assets and equipment are likely to operate a good condition for longer.

Note: The applications selected in this article are examples to show a feature in context and are not intended as endorsements or recommendations. They have been obtained from sources believed to be reliable at the time of publication.