Find the best Metal Fabrication Software

Compare Products

Showing 1 - 20 of 127 products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Sponsored: Sorts listings by software vendors running active bidding campaigns, from the highest to lowest bid. Vendors who have paid for placement have a ‘Visit Website’ button, whereas unpaid vendors have a ‘Learn More’ button.

Avg Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

A to Z: Sorts listings by product name from A to Z.

NetSuite

NetSuite

With an integrated system that includes ERP, financials, commerce, inventory management, HR, PSA, supply chain management, CRM and more – NetSuite enables fast-growing businesses across all industries to work more effectively by a...Read more about NetSuite

Fishbowl

Fishbowl

Fishbowl is the #1 manufacturing and warehouse inventory management software! Its powerful inventory control system gives your small or midsize business the exact tools needed to transform your inventory management and scale your ...Read more about Fishbowl

Striven

Striven

Striven is a cloud-based enterprise resource planning (ERP) solution suitable for many industries and organizations of all sizes. It offers features for accounting, inventory management, human resources, customer relationship mana...Read more about Striven

Global Shop Solutions

Global Shop Solutions

Global Shop Solutions offers ERP software to serve clients across manufacturing industries of all sizes. The multi-modular application is comprised of independent modules for customer relationship management, inventory management,...Read more about Global Shop Solutions

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Meet Eric, a software expert who has helped 1,534 companies select the right product for their needs.

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Tell us more about your business and an advisor will reach out with a list of software recommendations customized for your specific needs.

STEP 1 OF 4

How many employees are in your company?

Deskera MRP

Deskera MRP

Deskera enables fast growing businesses to operate more efficiently by providing them with an integrated platform that connects manufacturing, accounting, erp, inventory and warehouse management, order fulfillment, procurement, sa...Read more about Deskera MRP

REALTRAC

REALTRAC

Realtrac is an on-premise job management solution designed for job shop manufacturers and modular machine shops. It helps small and midsize manufacturers to schedule workflows, manage shop operations, track inventories, manage pur...Read more about REALTRAC

Visual EstiTrack

Visual EstiTrack

Henning Software has helped small to midsize manufacturers and job shops for 30 years. Visual EstiTrack ERP has complete material requirements planning, product lifecycle, supply chain, customer relationship, human resource and ma...Read more about Visual EstiTrack

DELMIAworks

DELMIAworks

DELMIAworks (formerly IQMS) ERP is developed specifically for SMB and large discrete and batch process manufacturers in the aerospace, medical device, automotive, food and beverage, consumer products, plastics, packaging, and elec...Read more about DELMIAworks

Aquilon ERP

Aquilon ERP

Aquilon Software offers a combined supply chain, manufacturing, distribution, and financial management system that is deployable either on the cloud or on-premise. All modules integrate with each other, allowing users to gain full...Read more about Aquilon ERP

Rootstock Manufacturing ERP

Rootstock Manufacturing ERP

Rootstock Software is a global provider of manufacturing cloud ERP on the next generation Salesforce Platform. It is purpose-built for mid-size discrete manufacturers who are looking to digitally transform on a future-proof platfo...Read more about Rootstock Manufacturing ERP

R4 Enterprise

R4 Enterprise

Royal 4 Enterprise is an integrated enterprise resource planning (ERP) solution with built-in modules for distribution, manufacturing, planning, inventory management, reporting and company financials. It serves midsize to large en...Read more about R4 Enterprise

OptiProERP with Sap Business One

OptiProERP with Sap Business One

OptiProERP with SAP Business One is a complete ERP solution for small and midsize manufacturers and distributors. SAP Business One is an ERP platform designed for small and midsize companies with over 70,000 customers. OptiProERP ...Read more about OptiProERP with Sap Business One

ALERE

ALERE

ALERE ERP, brought to you by TIW Technology, is a robust, modular manufacturing package that offers accounting, manufacturing, inventory management, CRM, service, analytics, document management, and data acquisition. Designed for ...Read more about ALERE

ProfitKey

ProfitKey

ProfitKey is an on-premise manufacturing management solution for small and midsize manufacturers and job shops. It caters to various manufacturing industries including aerospace, defence, automotive, capital equipment, electronics...Read more about ProfitKey

MRPeasy

MRPeasy

MRPeasy is a versatile cloud-based ERP system for small and scaling companies (perfect for up to 200 employees). The software offers a complete ERP solution with robust production planning and inventory management functionalities ...Read more about MRPeasy

Cetec ERP

Cetec ERP

Cetec ERP is a manufacturing enterprise resource planning software built for small and medium sized businesses. Cetec ERP's cloud-based software is designed to help these companies efficiently manage all aspects of their manufactu...Read more about Cetec ERP

Fulcrum

Fulcrum

Fulcrum is a cloud-based platform serving small/mid-sized manufacturers and job shops looking for a software platform that truly understands them and their unique, complicated processes. Humans weren’t meant to transcribe data fro...Read more about Fulcrum

IFS Cloud

IFS Cloud

IFS Cloud is a composable enterprise software application that orchestrates customers, people, and assets to reduce complexity, cost and risk as you plan, manage and optimize critical asset availability, strive for operational exc...Read more about IFS Cloud

QAD Adaptive ERP

QAD Adaptive ERP

QAD Adaptive ERP is a cloud-based solution for manufacturing businesses in the food and beverage, automotive, consumer products, industrial, life sciences, and high tech industries. It combines ERP, supply chain, finance, and cust...Read more about QAD Adaptive ERP

S2K Enterprise

S2K Enterprise

VAI is an independent software developer and the author of S2K Enterprise, an award winning cloud-based ERP solution utilized by customers operating across the distribution, manufacturing, specialty retail, and service sectors, wi...Read more about S2K Enterprise

Popular Comparisons

Buyers Guide

Last Updated: March 16, 2023Metal fabrication companies use all kinds of hardware technologies—from 2D laser cutting and robotic welding to even 3D printing. However, successful metal fabricators go a step further than just using hi-tech equipment. They also use software to ensure that their teams meet production deadlines and maintain high standards of quality.

Known as metal fabrication software, and part of the larger category of manufacturing systems, these solutions help metal fabricators manage different business operations. A feature of metal fabrication software is inventory management that's used to track materials and equipment located in different facilities.

However, selecting a metal fabrication tool may not always be an easy process because you have to factor in the scale and size of your businesses to find the right tool. In this buyer's guide, we will help you understand the common features of these tools and things you should consider when evaluating software.

Let's get into the details!

Here's what we'll cover

What Is Metal Fabrication Software?

Common Features of Metal Fabrication Software

What Is Metal Fabrication Software?

Manufacturing businesses (i.e., fabrication shops) need software to handle projects. The software helps them from the time they bid for a contract to the final quality check of the finished product. It also automates inventory tracking, project scheduling, project cost calculation, quoting and bid proposal generation.

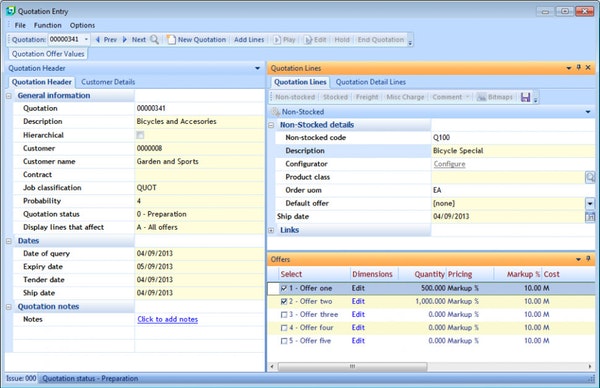

Calculating project costs and creating quotations in Syspro

Small businesses that use metal fabrication software will see tangible benefits such as better production planning, faster creation of bid proposals and optimal equipment utilization. The software will also help you eliminate the use of spreadsheets, which are prone to manual errors and waste a ton of employee time.

Common Features of Metal Fabrication Software

In this section, we have shortlisted the wide-ranging features of manufacturing systems. These are the most common functionality that small businesses can expect in metal fabrication software.

Document management | Create a centralized file repository of the drawings of product models, change orders, request for information (RFI) and other project-related documents. |

Inventory management | Automatically sort and track raw materials, stocked items, work-in-progress (WIP) items and finished products using serial or lot numbers. |

Estimating and quoting | Create project cost summaries by automatically calculating labor and materials costs. Use this information to generate bid proposals. |

Production planning and management | Understand the status of existing work orders, or assign new ones to employees, on visual dashboards. Also, plan job completions using Gantt charts. |

Materials management | Calculate the requirement of materials and track the usage of equipment for the optimal utilization of equipment and materials. |

While these features are common to most metal fabrication tools, there could be variations in the depth of functionality and ease of use. Also, different vendors offer different integration options. For this reason, it's essential that you fully explore a tool's functionality to assess whether or not it meets your specific business requirements.

What Type of Buyer Are You?

Getting the right metal fabrication software for your business means analyzing the size of your organization and your software budget. To help you understand the different categories of buyers in this market, we have divided them into the following types:

Full-suite buyers: Large fabrication shops that work on varied projects, such as additive manufacturing, and use robotic automation will have complex needs. They want a one-stop solution for all their manufacturing needs. For instance, a full-suite solution will have built-in CAD tools so that designers can create 3D models for custom fabrication requests.

Small manufacturers: These buyers may not need advanced features but are looking to automate their wasteful manual processes. They need an easy-to-use solution that offers inventory management and project tracking so that they can improve their production speed and quality.

Once you identify the category that you fall under, the next step is to think about the type of software you need. Read about these considerations in the next section.

Key Considerations

When you're shopping for software to use in your business, you need to keep certain things in mind such as software deployments and the use of mobile devices. Here are the top considerations to review vendor offerings before you purchase a solution:

Deployment options: For small fabrication shops, the ideal deployment would be in the cloud over on-premise due to the high upfront license costs of the latter. On-premise tools require you to handle software maintenance and data backup on your own. Therefore, opt for a cloud-based tool that has a smaller monthly subscription fee and the vendor is typically responsible for software upkeep.

Integrations offered: Third-party integrations are important for seamless data transfer between different systems. For example, integrating accounting software will help you create detailed financial reports about your profitability over time, while integrating CAD software will help you import 3D images and drawings. In general, integrations become essential to a small business as it grows and needs more complex systems to meet its requirements.

Mobile accessibility: This is important if your employees don't have fixed workstations. For instance, if you have a designer working remotely, then the ability to receive and send drawings on mobile devices makes processes very convenient. Similarly, warehouse workers can log in the information of new inventory from their mobile devices.

Market Trends to Understand

Among the many trends affecting the manufacturing industry, here are some of the most important ones:

Build complex prototypes with 3D printing: Fabrication shops have many uses of metal 3D printing systems that can be integrated with CAD software. This helps them quickly print prototypes and small parts with complicated designs. The technology is especially beneficial for custom fabrication businesses that cater to a wide array of industries such as aerospace and healthcare.

Track inventory easily with smart tagging: Advancements in inventory tagging, such as radio frequency identification (RFID), have solved many challenges of tracking and managing the records of equipment and materials. For instance, a business can monitor the status and availability of equipment remotely with RFID tags. This technology helps metal fabrication shops optimize the stocking of their inventory and prevent theft.

Automate equipment maintenance with Internet of Things (IoT): Manufacturing businesses can use IoT in many ways. For instance, install sensors connected to the internet at the site for automated equipment monitoring. Instead of employees manually checking the health of different systems, the sensors will constantly fetch data and automatically send alerts for any maintenance requirements. With predictive maintenance, businesses can prolong the life of equipment and prevent accidents.