How Manufacturing Warehouse Management Simplifies Today’s Complex Supply Chain

Consumers have more choice than ever—increased customization and personalization, flexible shipping options, real-time package tracking—and, in turn, expect and demand more.

This puts manufacturers in a tough position to either adapt to the increasing complexity or lose customers to more agile competitors.

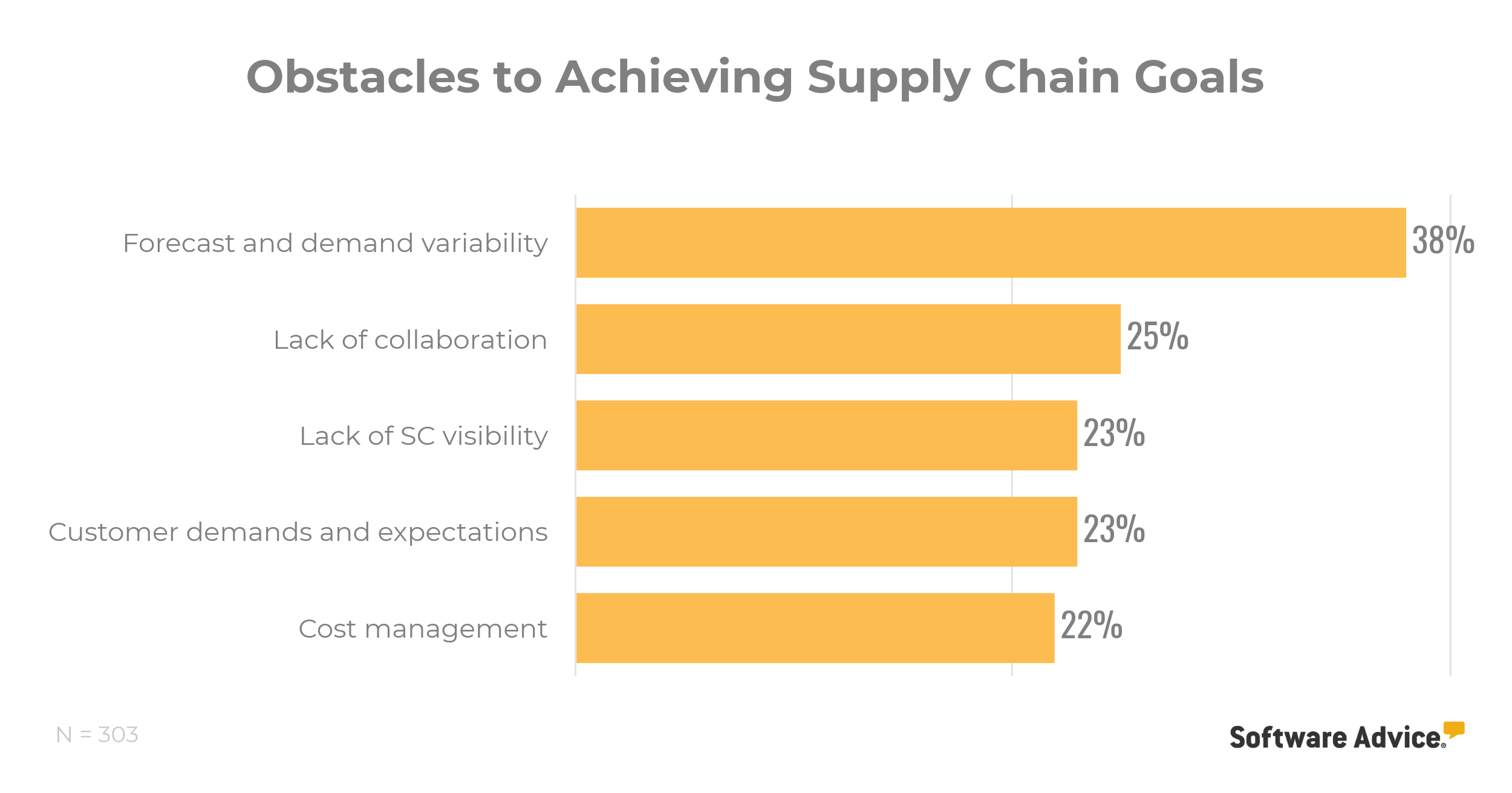

A recent Gartner survey of manufacturers and supply chain professionals shows that unpredictable demand and a lack of transparency and collaboration with the supply chain present a significant barrier to reaching business goals. (Full content available to Gartner clients.)

But when manufacturers evaluate the sources of complexity and optimize their warehouse management, they can efficiently meet the growing variable demand while increasing their view of the supply chain. Below we’ll dive into how to achieve this.

Here’s what we’ll cover:

Spot External Trends That Increase Complexity

Identify Internal Trends That Contribute to Complexity

Evaluate Complexity of Interfaces/Integrations

How Do I Find the Right Warehouse Management Software?

Spot External Trends That Increase Complexity

Forces outside of your manufacturing organization impact your flexibility and efficiency, and the boom of e-commerce continues to ripple through the supply chain with serious effects. Gartner notes that external changes result in a rise in pressure to:

Give customers more choice

Deliver smaller amounts more quickly

Handle returns more flexibly

Delivering on these outside forces “naturally builds more effort and complexity into the average order.”

While you likely aren’t able to directly control these external factors, to optimize your warehousing and ability to meet production demands, you must at least identify what they are.

Factors likely include:

Customer expectations | Consumers expect companies to provide increasing convenience, personalization and customization |

More SKUs | E-commerce gives customers more choice, and as companies offer more product variation, they also have more SKUs to manage |

New products | Introducing new products to meet demand can causes more organizational issues |

Data | All these changes add to the growing lake of data that manufacturers struggle to make valuable |

You may notice these factors all have a direct impact on warehouse management, which in turn, creates complexity in many other parts of the supply chain. Maybe you can’t control these factors, but you can get a grasp on the volatility by answering the following questions with your team and management:

What seasonal spikes or dips do you expect each year?

Which customer expectations add the most complexity to our operations?

Has there been or is there expected to be growth in product range?

Has your industry been subject to regulatory shifts? Do you expect any?

Identify Internal Trends That Contribute to Complexity

You’re likely to find internal operational issues to address to positively impact production and the warehousing function.

These can include physical infrastructure and labor, inbound and outbound processes—receiving, storing, picking and shipping—as well as supportive functions like quality control, inventory management and automation.

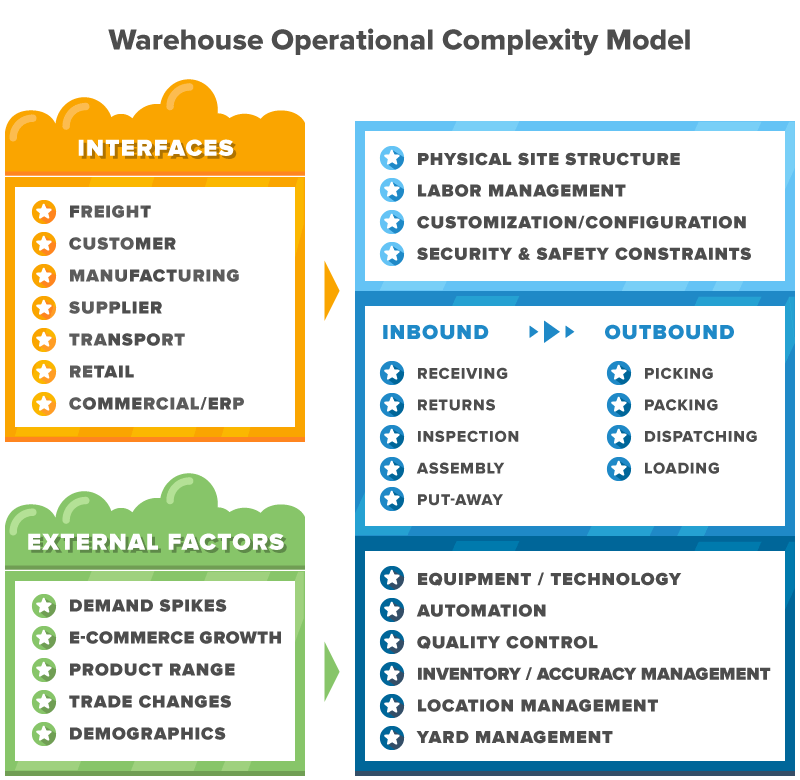

Gartner’s Warehouse Operational Complexity Model visualizes the external factors, interfaces with other service providers along the supply chain and the internal processes you can control (in blue).

A version of this image originally appeared in “Determine Warehouse Operational Complexity to Maximize Operational and Warehouse Management System Efficiency” (content available to clients)

You must evaluate all of these internal processes to remove bottlenecks and redundancy—this will simplify the warehouse operations so your teams can focus on production. Gartner recommends assigning teams to review each component and identify any ways to maintain the same effect with less complexity.

As an example, let’s say we’re evaluating the receiving process. Elements of this process will likely include:

Seal verification | Driver recognition | Receipts (for parcels, shipping containers, pallets etc.) |

Cross-dock receiving | Supplier system receiving | Fast-track receiving |

Unlike external forces, any or all of these internal components could be tweaked internally to trim tasks that don’t create value nor maintain quality. Gartner suggests asking these detailed questions to understand how exactly to improve the receiving process:

Is there pre-receiving functionality?

What are the receiving methods (for example, blind receiving, batch receiving and decremental receiving)?

Is dock door scheduling a part of the receiving process?

Are supplier and customer booking requirements recorded?

Do you have a process to verify the accuracy of goods in/out?

Are alerts or triggers in place to prompt weighing and measuring product on receipt wherever this information is missing?

Is the WMS configured to route product to specific receiving areas? Or are those decisions made after physically viewing the product, thus causing congestion and added complexity?

Evaluate Complexity of Interfaces/Integrations

Integrating the manufacturing software with other systems in the supply chain help to create a more visible, more predictable production environment for everyone involved. But the configuration of these interfaces can often be simplified as well.

A modern supply chain setup typically includes integrations among a variety of departmental systems (an ERP, order management, transportation management) and sometimes third-party software from external partners (suppliers, maintenance, 3PL providers).

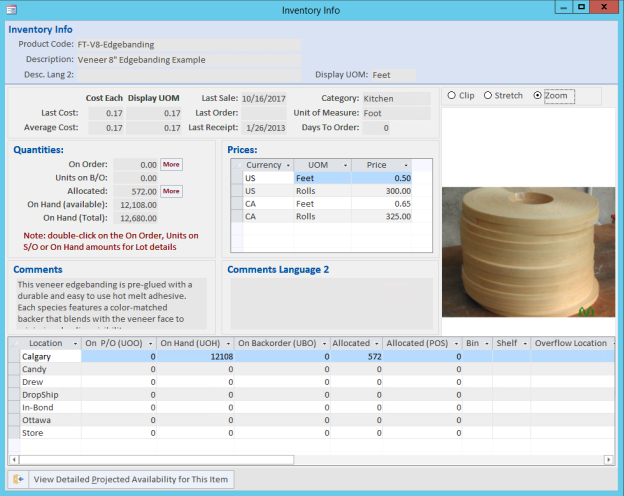

Many ERP systems, like Blue Link ERP, allow users to integrate with supplier and carrier inventory data so manufacturers can react to supply changes quickly (Source)

Again, duplicated activities are common targets for elimination when evaluating integration complexity as well. You also have the opportunity to enable or improve data collection—All the valuable information flowing back and forth can be leveraged to assist with identifying trends, anticipating delays and forecasting for demand.

Review your integrations for complexity:

Are the integrations confined to a single software vendor? Or are several disparate systems in use?

How frequent are the feeds from each interface, and how does this impact your manufacturing efficiency?

What is the expectation on responsiveness to the new interface setup?

How Do I Find the Right Warehouse Software?

Most manufacturers today use an enterprise resource planning (ERP), or a post-modern version assembled with various systems, for a holistic view of operations.

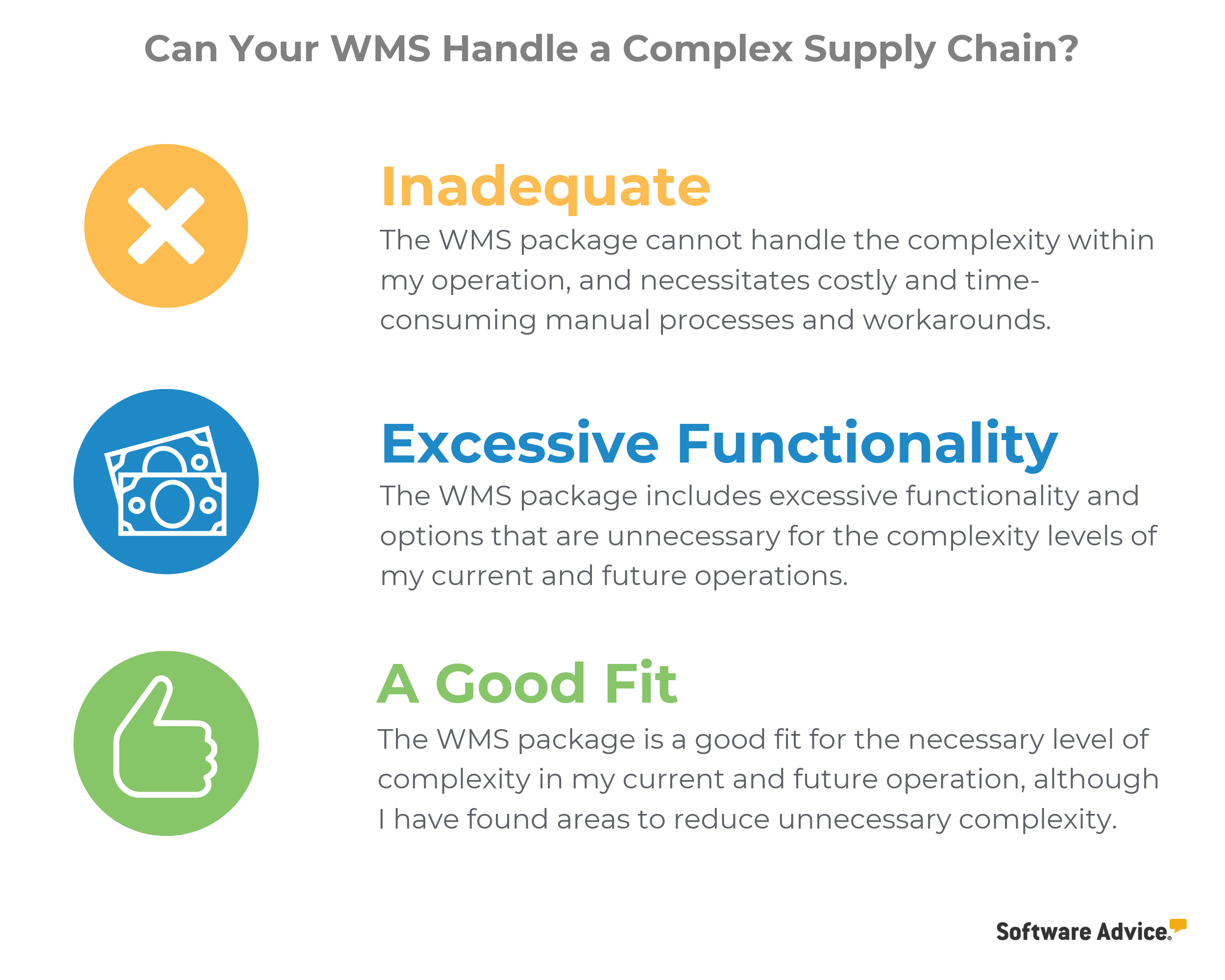

After reviewing the internal, external and integration factors that contribute to your complexity, you’ll be able to determine whether your current warehouse management system (WMS) is robust enough:

Because the market for manufacturing software is evolving, a warehouse management system (WMS) may not be included in every package. In this case, we’re here to help.

Our manufacturing software advisors can help you find the best WMS for your organization during a free phone consultation at (855) 998-8505. In less than 15 minutes, they narrow down your best options based on your actual needs.

Note: The information contained in this article has been obtained from sources believed to be reliable. The applications selected are examples to show a feature in context, and are not intended as endorsements or recommendations.