How Barcodes and Inventory Control Tackle Your Top Challenges

Storing and managing inventory makes up a significant portion of a company’s costs each year—and poor inventory practices can tank a business.

When you need to account for each item in near-real time, automating the inventory management process becomes much more valuable. Add in barcoding and you have the right mix of solutions for a growing business.

We surveyed inventory management professionals to find out their top challenges, what methods they use to tackle them and how they connect a barcode and inventory control.

Key Takeaways:

Most businesses that use manual methods like spreadsheets experience the challenge of performing audits and keeping counts updated. [Read more]

Companies tend to more frequently rely on inventory management software as the size and complexity of an inventory increases. [Read more]

The versatility and affordability of barcodes make them the most popular choice—over QR codes or RFID tags—for inventory management purposes. [Read more]

Software With Barcoding Solves Biggest Inventory Problem

Only using static spreadsheets to manage inventory tasks introduces many issues:

Leaves too much room for human error

Makes performing counts extremely time-consuming

Throws off accuracy of your data

And to make matters worse, we found that a majority of respondents still rely on manual methods:

Method of Inventory Management

Only 40 percent of our respondents use some kind of inventory control system, whether as a larger part of an enterprise resource planning suite or retail system, or as a standalone inventory product.

Automation is your friend when it comes to inventory management. A barcoding and inventory system can work together to offer a simple way to update counts automatically, offering your organization the following value as well:

Minimized stock-outs by optimizing the reordering process

Lowered costs from a reduction in stocking levels

Improved customer service by using real-time inventory data to offer an accurate order status

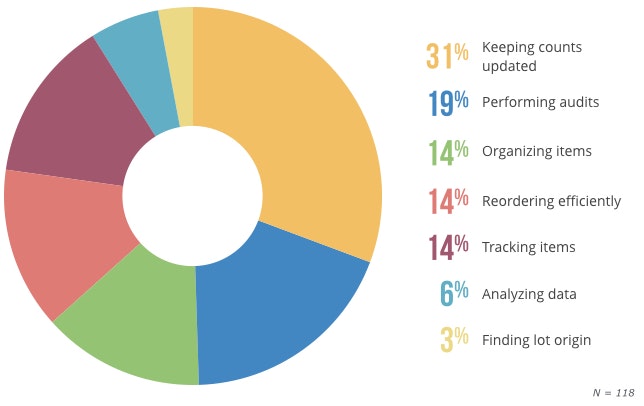

Top Inventory Challenges for Spreadsheet Users

The top challenge for those who manage inventory with spreadsheets is keeping counts updated (31 percent) followed by performing the audits to update the numbers (19 percent).

Tracking, organizing and reordering inventory (14 percent each) is a common issue as well when using spreadsheets and separate systems to manage each process.

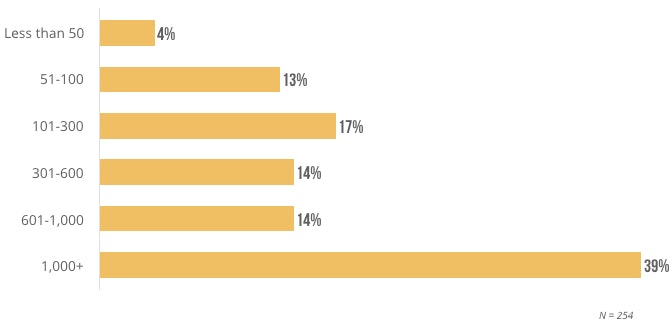

Software Value Increases with Inventory Size

As an inventory size grows, the time you must spend maintaining it increases. Keeping track of thousands of items, managing several vendors and reordering in an efficient way all takes work.

That’s why software use increases as the reported size of a company’s inventory grows. We see a huge jump in software use when inventory size exceeds 1,000 items.

Software Users by Size of Inventory

Automation helps more with big inventories, and adopting software to manage inventory gives companies the ability to scale up quickly without losing efficiency.

Barcode scanners make it easier to physically count large quantities of items, but they also help manage a growing inventory’s increasing complexity as you work to maintain categories that can include:

Type

Cost

Dimensions

Location

Model

Serial numbers

Custom reorder quantities

As you use software to track these details, you build up useful data that you can analyze with reporting features within your inventory management software. This helps reveal trends about your most popular products, most profitable items or areas for improvement.

Next, we’ll see how barcoding in particular offers the best benefits for most types of organizations.

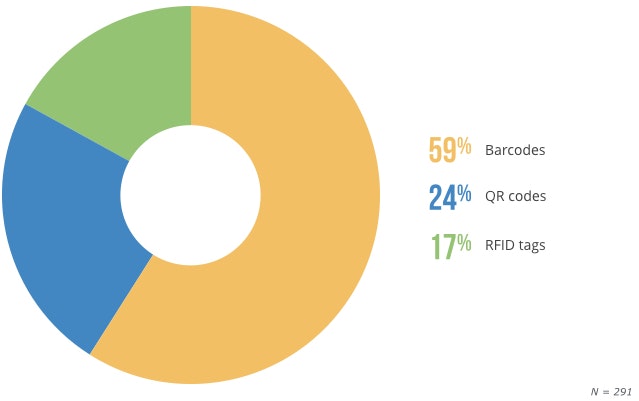

Barcode Ease-of-Use Makes Them Most Popular

We see barcodes everyday in retail, but they’re also used heavily in manufacturing, asset management, food service, maintenance and several other industries.

In each, barcodes are most common because they’re cheap, simple and effective for nearly any size or type of item. Nearly 60 percent of our respondents use barcodes over two other common types.

Types of Codes Used for Inventory Management

In a past article, I detailed the uses and advantages of RFID tags, used by 17 percent of the respondents. There are significant differences among these scannable tag or code types:

| Barcode | QR Code | RFID |

Scanning | Requires line of sight | Requires line of sight | Can be scanned through many types of materials |

Range | Close to a few feet | Close to a few feet | Certain tags can be scanned hundreds of feet away |

Read Rate | One at a time | One at a time | Scan potentially thousands of tags at once |

Matrix | One dimensional | Two dimensional | None |

While RFID tags offer much faster scanning, they’re more expensive and take more time to implement properly. For most organizations, it makes more sense to stick with barcodes as your inventory needs grow.

How Do I Get Started With Inventory Automation and Barcodes?

Modern inventory management software can be quickly set up with a barcoding solution to handle the more time-consuming parts of the process.

Maybe you have an inventory with fewer than 100 items and a spreadsheet is enough for now. However, you need to automate inventory management if you have:

a high volume of different items

multiple warehouse or retail locations

a plan to scale the business

Getting started is as simple as checking out our inventory management software page for reviews of the best systems with barcoding functionality. Then you can call our advisors at (844) 680-2046 for a free phone consultation to find the right product