How to Outsource Manufacturing Without Losing Money—Or Worse

Outsourcing a manufacturing process is a high-risk, high-reward proposition. Cheaper, quicker and more flexible production is possible through outsourcing, but you’re at risk of facing serious financial or legal problems that could sink your entire business.

Despite these risks, the benefits are compelling and the opportunities are growing: A recent Gartner survey shows 65 percent of manufacturers currently outsource parts of their production, and another 21 percent plan to outsource in the next couple years.

Outsourcing isn’t to be taken lightly or without help. By considering these three key factors, manufacturers can avoid common pitfalls and strategically outsource non-core parts of production to significantly improve efficiency while reducing cost.

Determine What Processes Are Not Core to Your Business

Outsourcing strategically means picking specific parts of production for partners to complete—parts that are not core to your business.

Some production processes can be performed by external partners more quickly, at a higher ROI and with specialized technology. In a case like this, it behooves you to outsource, says William Crane, founder and CEO of IndustryStar Solutions, which provides on-demand supply chain and technology services.

“If [the process] is not a core competency of your firm and it’s just a task that needs to be done as part of the value chain,” he says, “some of the more forward-thinking companies are asking, ‘Should I be in that business?'”

Crane works with many small and midsize businesses (SMBs) to help optimize parts of their supply chain. A major aspect of his company’s work includes analyzing the manufacturing components within a business to find parts appropriate for outsourcing.

First, manufacturing managers should establish clear business goals for outsourcing during discussions with other departments. Remember that there are many more potential benefits from outsourcing than just cost savings. These benefits may be increased flexibility and reliability or the ability to free up time to focus on other initiatives.

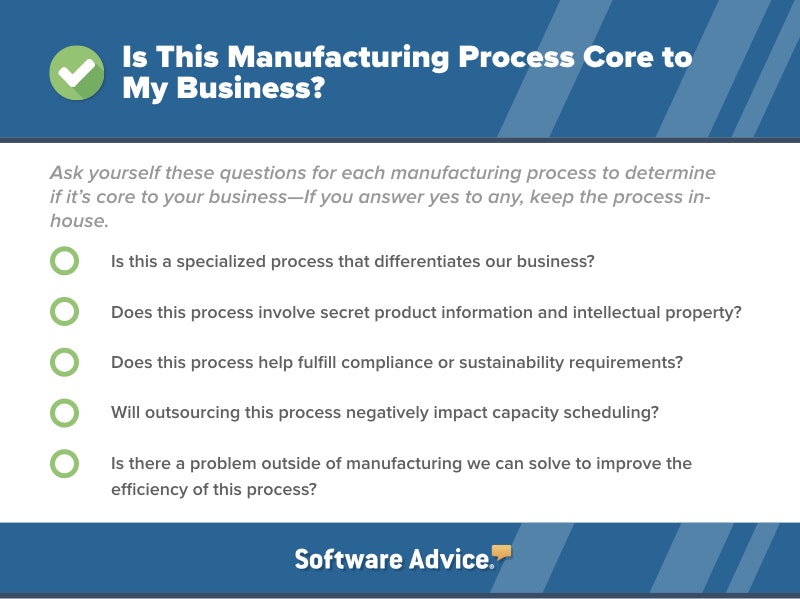

Next, review all the manufacturing components for the process you intend to outsource. Crane recommends evaluating five factors of each process to determine whether it’s a fit for outsourcing:

Cost: Will outsourcing this process reduce my costs?

Skill: Do external providers have the skills necessary to perform this process?

Risk: Does outsourcing this process create a risk for my company?

Speed: If I outsource this process, will it result in faster production?

Innovation: Will outsourcing this process give my company a competitive advantage?

The risk factor is important—outsourcing without the right preparation or oversight can lead to disastrous results.

Case Story: Mattel Recalls Thousands of Toys From Outsourcing Problem

Gartner points to a 2007 case when toy company Mattel recalled more than 430,000 die-cast cars containing “impermissible levels of lead” in the paint. These toys were manufactured in external Chinese factories Mattel contracted to produce the toys.

The incident was spread in the media, cost millions to cover the costs and spurred the company to shift production into Mattel-owned and operated factories.

Mattel is a massive company, so even a significant recall isn’t likely to take down such an enterprise. But small and midsize companies may not recover from a similar kind of mistake, Crane says.

“There’s pain, and then there’s ‘not-going-to-be-around-next-week’ pain,” he says.

In addition to the five factors above, Gartner also offers the following questions to ask when evaluating manufacturing processes.

Identify Partners With Corresponding Skills

As mentioned above, the external manufacturing marketplace has grown and diversified to offer other businesses a wide range of services to complement their own. In addition to manufacturing processes, consider outsourcing other areas that could impact your business goals.

These other areas may include:

Designing and engineering

Supply chain visibility

Procurement and material sourcing

Logistics and inventory management

Supply chain risk management

Aftermarket services

Software and technology solutions

Reviewing your needs for these services can reveal ways to deepen the benefits of outsourcing for smaller, less capable companies.

“Whether it’s manufacturing related or other functions, I’m a big advocate of [outsourcing], especially for small to midsize businesses, because your resources are constrained and you have a certain budget,” Crane says.

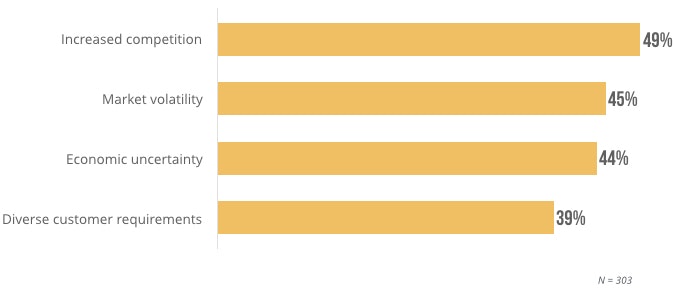

According to a recent Gartner study on outsourcing (content available to Gartner clients), other pressures are driving more manufacturers to outsource a variety of tasks:

Factors Impacting Business Goals

Once you’ve decided on a list of non-core processes that are fit for outsourcing and which align with your business goals, take these steps:

First, create an RFP document that contains the requirements and skills to meet these goals. This will serve as your roadmap when evaluating service providers and help prevent you from being overwhelmed by the huge variety of options.

Next, think beyond the scope of your current requirements and request for optional related services to be bid on individually. As business goals and needs shift over time, you can contract other services that drive new initiatives with minimal interruption.

Organizations such as IndustryStar are available to help you find and partner with external service providers. Certain types of software, such as manufacturing ERPs or supply chain management systems, also offer functionality to help find and manage those partnerships.

Evaluate Outsourcing Benefits Aside From Cost Savings

Contracting another company to manufacture parts of your finished product more efficiently than you can is likely to save money.

“But usually from our experience, it’s a little deeper than that,” Crane says.

As you begin to reach out to external companies to gather information about their capabilities, don’t neglect exploring the many other possible benefits outsourcing can deliver. In fact, a boost in agility and flexibility—to unlock more production capacity and increase changeover speed—is the most common goal with outsourcing.

Top Reasons for Using External Manufacturing

First, Crane recommends manufacturers choose an external service provider that delivers benefits that align with your overall business goals. Don’t simply choose the company that can offer the most cost reductions. The right provider may use specialized technology that vastly improves quality and contributes to your goals. Factor in capabilities and risks, as well as costs.

Next, gather all relevant stakeholders to identify other hidden variables. It’s important to loop in representatives from several other departments because a huge array of factors can impact (or be impacted by) the outsourcing process. Use this group to help create a list of non-core processes and requirements that could present potential issues before they cause real problems. Include representatives from:

IT

Engineering

Product development

Supply chain management and/or procurement

Finance

Customer service

I’m Ready to Outsource! What’s Next?

Fantastic! We have more research to help you improve important parts of the manufacturing process and resources that help you evaluate software.

Learn more about how manufacturing software helps companies improve their in-house production, manage maintenance for assets and boost safety compliance.

Read reviews from real manufacturing software users to identify systems that can help you manage relationships with external manufacturers.