5 Effective ERP Reporting Strategies for Your Manufacturing Business

The E in “ERP” doesn’t stand for “enormous,” but it might as well.

Enterprise resource planning (ERP) software houses everything from core financial data to production cycle times, consolidating the many facets of your manufacturing business into a single unified system. As you can imagine, that’s an enormous amount of data.

In some ways, this massive data pool works to an ERP’s advantage. Through analytics dashboards and detailed reports, this abundance of information empowers users to make confident business decisions, offering insight into the interconnectivity of business processes and how they contribute to organizational performance.

At the same time, though, the vast size of an ERP system can make it difficult to identify which data points to track, how to best visualize the data set, or even decipher what the heck it all means.

Don’t worry, all is not lost.

Small manufacturers can make confident business decisions by prioritizing data integrity and reporting development, dedicating adequate resources to data management and scaling back on the amount of data they track.

Here’s how to master the reporting craft:

Make Sure Your Data Is Clean and Accurate

Track Only What You Need to Track

Allocate Resources for Data Collection, Analysis and Support

Include Reporting Development in Future Growth Plans

Choose an ERP With the Right Reporting Capabilities

Make Sure Your Data Is Clean and Accurate

If you want quality reporting, you’ll need quality data. In other words, you’ll need a little thing called data integrity.

Data integrity is exactly what it sounds like: Whether your data is lying to you or not. If duplicate metrics are inflating your reports, if results are being skewed by uneven formatting or if your data is just flat out inaccurate, the integrity of your ERP data can have a major impact on your reporting capabilities. For small businesses that often lack the resources to absorb such mistakes and rounding errors, the stakes are even higher.

So how do you make sure your data is clean and accurate? Gartner recommends the following:

Empower the CEO to assign responsibilities for data management.

Consult the CEO to determine integration objectives.

Establish data standards with a formal style guide.

Don’t lose sight of the big picture.

Manage data in a single location, but distribute accountability across the business.

For more in-depth analysis, give this article a read.

Track Only What You Need to Track

You’re probably familiar with the phrase “less is more”; the maxim applies here, too.

Nothing’s more certain to muddy up your ERP reports than a bunch of data you don’t need. Instead of analyzing every data point under the sun, focus on the metrics most aligned with your business objectives (e.g., production costs instead of website traffic).

This is especially true for manufacturers that have only just begun to implement their ERP system—start small, then add more to your data mix as needed.

And remember, prioritization is the name of the game. If you’re unsure about what to track, build a hierarchy of metrics that best align with your objectives and work your way down ladder.

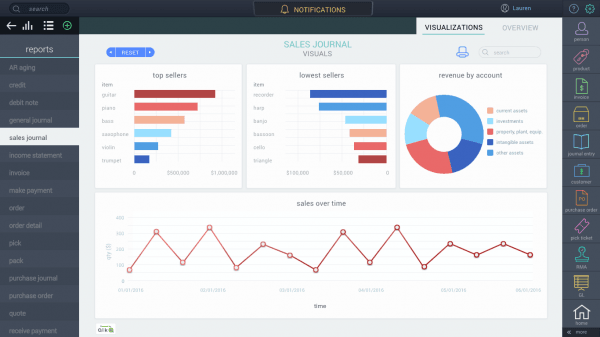

Here’s an example of a no-frills report in Paragon ERP, highlighting basic sales data:

Paragon ERP dashboard (Source)

Given the metrics they’re tracking, the above business likely prioritizes raw sales and revenue over profit, which isn’t included within this dashboard. The end result is a clean, easily digestible overview of sales performance.

Allocate Resources for Data Collection, Analysis and Support

As the manufacturing industry becomes more data-driven—and it’s happening, fast—the more important it is to have dedicated data analysts who gather and analyze the most consequential aspects of your ERP reporting output.

For many small manufacturers, hiring full-time analysts isn’t a viable option, in which case they ought to consider contracting a consultant or support specialist. Most ERP vendors offer built-in support services that can help you get the most out of your reports, which can be a temporary but cost-effective fix for cash-strapped organizations.

But vendors can’t build your dashboards for you—at least not without your help as a business owner—so be sure to have a communications plan that clearly identifies agreed-upon business objectives and their correlating data points. This same principle applies to internal analysts and anyone who works with these dashboards, so be sure that leadership is guiding the process and outcome regardless of who you’re working with.

Prioritize Reporting Development in Future Growth Plans

The world generates more than 2.5 quintillion bytes of data every day, and 90 percent of all the data on Earth was created in the last two years alone. Chew (or maybe byte?) on that stat for a minute.

But if you think data is a big deal today, just wait until a year, five years, 10 years from now. We live in a metrics-driven business climate, and with each software update, ERP systems—and, by extension, businesses—get better at isolating, deciphering and correlating key performance metrics.

Given how manufacturers are leveraging ERP data to gain new insights and competitive advantages, any self-respecting growth strategy ought to not just include reporting, but prioritize it.

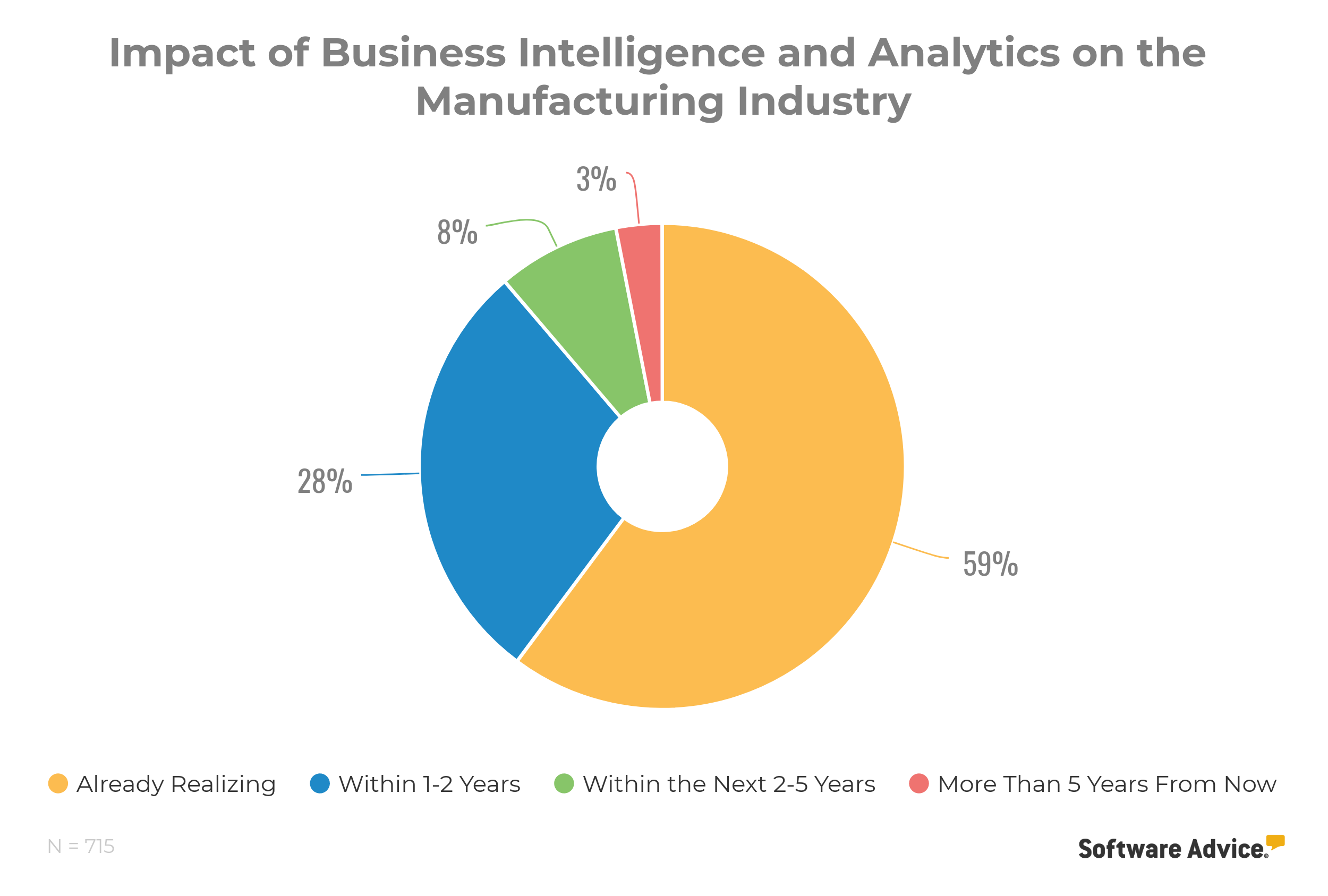

In Gartner’s 2018 Tech Trends Survey, 59 percent of manufacturing organizations that are using BI and Analytics tools are already realizing a significant impact of it on their business. Another 28 percent expect to feel it within the next one to two years.

Choose an ERP With the Right Reporting Capabilities

One of the most significant advancements in the ERP space is how customizable it has become in recent years. The rise of integrations, customizations and postmodern deployments has afforded SMBs the ability to tailor their systems to the unique needs of their business.

For manufacturers, this means production-focused reporting with the metrics that matter most to your organization.

Check out this infographic for a detailed rundown of the reports manufacturers need to focus on.

Whether it’s an ERP designed specifically for manufacturers or an integrated suite of disparate software platforms, it’s easier than ever to get exactly what you need out of your reporting.

For starters, check out the more than 150 ERP vendors listed on our website, complete with features, pricing and reviews from verified customers. Have questions? Give us a shout at (855) 998-8505 and talk to a real-life software advisor with a free 15-minute phone consultation.

Information on Gartner’s Top Technology Trends for SMBs Survey Gartner conducted this survey in June and July 2018 among 715 U.S.-based SMBs, with more than one employee and annual revenue of less than $100 million. The survey excluded nonprofit organizations. The qualified respondents are decision-makers, or have significant influence on the decisions related to purchasing technologies for their organization.