How New ERP Technologies Are Impacting Small Manufacturers

The software landscape is changing faster than you can say “enterprise resource planning.”

As new ERP technologies like AI, cloud computing and blockchain emerge, so do new frontiers in how businesses operate and produce goods, offering groundbreaking operational efficiency and insight into workflow processes.

One industry that’s been completely disrupted is manufacturing.

Most digital enhancements offer clear benefits for small manufacturers, whose businesses leverage sophisticated supply chain processes to produce and distribute goods. Yet the speed at which the landscape changes raises some questions:

How can small manufacturing companies identify the technologies that best suit their business?

Furthermore, how can they utilize these advancements in the ERP space to streamline and grow their business?

By taking a measured, selective approach to new ERP technologies, small manufacturers will gain access to efficiency enhancements that will help them streamline their business as they grow.

The tech advancements having the most profound impact on manufacturers include:

Let’s take a deeper dive.

Cloud Computing Makes ERP Data More Portable and Accessible

Imagine you’re on the factory floor and get a sudden urge to access real-time ERP data from your smartphone. Or maybe you’re visiting a prospective business partner and need to reference some analytics.

Cloud-based platforms empower manufacturers to do these things, offering a level of convenience and mobility that on-premise ERP systems simply cannot match.

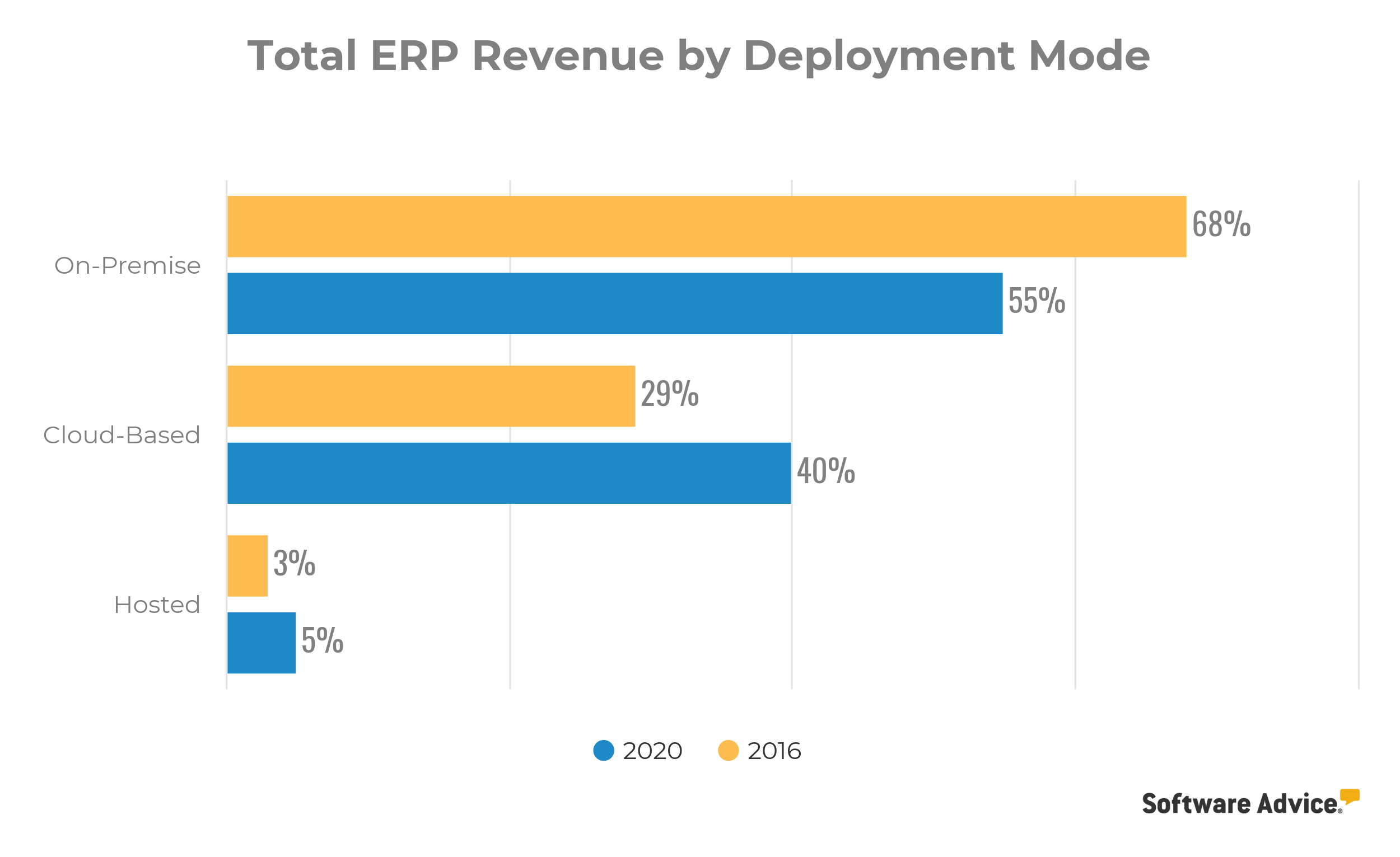

Despite these benefits, Gartner research shows that the manufacturing industry has been slow to adopt the technology, with just 5 to 20 percent penetration in a still-adolescent market. Gartner also predicts that in 2020, only 40 percent of ERP deployment revenue will originate from cloud-based apps—just an 11 percent increase from 2016. (Research available to clients.)

However, enterprise-level businesses—especially those entrenched in robust, hard-to-upend legacy ERP systems—are the ones accounting for most of that on-premise revenue. This leaves an opening for smaller, more agile manufacturers to take advantage of the more accessible Software-as-a-Service (SaaS) pricing models associated with cloud platforms, which typically offer lower upfront costs.

CHALLENGES:

Most cloud-based ERPs are still green and underdeveloped, typically lacking the functionality, customizability and ease of integration associated with on-premise systems.

While subscription-based SaaS pricing models are convenient for small manufacturers initially, they’ll likely cost more than traditional ERPs after several years of use.

OPPORTUNITIES:

The convenience and flexibility of cloud-based platforms and smartphone integrations allow businesses to access real-time ERP data on the go.

By eliminating the costly implementation and ongoing maintenance demanded by on-premise ERPs, cloud-based systems give small manufacturers the freedom to allocate resources where they need them most.

Priority: Optional

The future of ERP software is trending toward the cloud, but on-premise systems are far from a dying breed. To determine whether a cloud-based ERP is right for your business:

Establish whether cloud ERP has the functionality required to run your day-to-day business operations.

Assess your business’s existing IT infrastructure and which deployment model it is best equipped to handle.

Determine whether the subscription-based SaaS model, with its lower upfront costs but greater long-term commitments, is financially optimal for your business.

Artificial Intelligence Means a Smarter, More Efficient Supply Chain

Recent advancements in AI and machine learning have transformed the manufacturing industry. Could a fourth Industrial Revolution be in our midst?

The efficiency enhancements forged by AI will have far-reaching and long-lasting effects. Yet automation and business insights are just the beginning. As the technology matures and becomes more universal in application, small manufacturers will experience a drastically smarter supply chain that can do wonders for a bottom line.

The influence of AI will manifest in discernible advancements like chatbot-powered order processing, autonomous delivery vehicles and even a process known as generative design, which finds the optimal blueprint based on a predetermined set of resource parameters.

Business owners are already prioritizing AI, too. Gartner’s 2018 Tech Trends Survey of small and midsize businesses found that 41 percent of respondents had already felt the impact of AI technology on their business, while another 42 percent expect to realize its potential within the next two years.

CHALLENGES:

Because of its relative complexity and newness to the market, there is currently a limited pool of AI-focused personnel, and a dearth of thorough research data and roadmaps for implementation.

Many small manufacturers might not have the resources to fully utilize the technology.

OPPORTUNITIES:

Through efficiency improvements and deeper analytical insight, AI presents small manufacturers with a unique opportunity for short- and long-term cost savings and revenue generation.

Priority: Critical

While the true power of AI hasn’t been fully unleashed (yet), the technology is mature enough to have tangible effects in the ERP market—even for small and midsize businesses. Your competitors are already reaping the benefits; don’t let your business fall behind. When evaluating how AI can benefit your organization:

Pinpoint the explicit ways in which your ERP vendor integrates AI into reporting insights, workflow automation and other routine business tasks.

Specify the practical applications for your organization and how it fits into your broader ERP strategy.

Assess whether your business has personnel with the experience to know how to best leverage the technology.

Big Data Empowers Businesses to Make Smarter Decisions

Society’s growing reliance on data to inform the decision-making process can be felt from the factory floor to the baseball diamond.

As the “crown jewels” of your manufacturing operations, ERP systems combine information from disparate business processes into a unified, data-hoarding whole.

In other words, there’s a lot of actionable data in your ERP. The manufacturing industry generates an estimated two exabytes of data every year; for those who are keeping score, that’s two quintillion bytes—more than any other vertical.

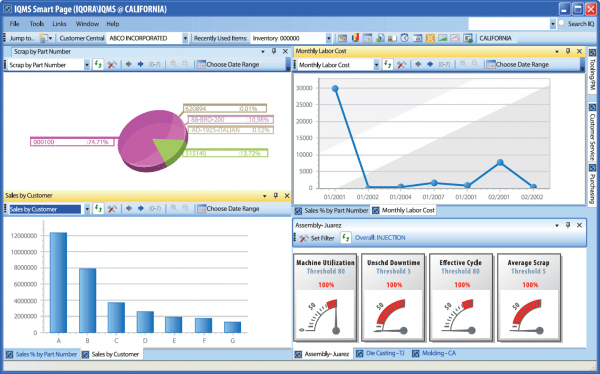

Manufacturers can access these insights through embedded analytics, customizable dashboards and detailed reporting metrics, all of which are available in most modern ERP systems.

By enhancing the visibility of key performance indicators, managers can confidently assess whether to increase product output in markets with high demand, identify inefficient delivery routing or other rifts in the supply chain, and even design innovative new products with predictive analytics.

IQMS Manufacturing ERP dashboard (Source)

CHALLENGES:

Data alone won’t help grow your business. Those who call the shots must first be able to identify and prioritize the most meaningful information, then be discerning and purposeful in how they analyze, interpret and implement it into their objectives.

OPPORTUNITIES:

With so much data at their disposal, small manufacturers have more insight into their business operations than at any point in history.

Decision-makers can leverage analytics and reporting tools to identify new opportunities for growth and efficiency enhancements.

Priority: Critical

If it’s not already, data should inform and influence every business decision you make, from big-picture financial investments to whether your office should be dog-friendly. When determining how to prioritize your business data:

Establish the specific data points that best measure the progress of your short- and long-term business objectives.

Research how the interconnectivity of your ERP data provides insight into the cross-departmental effects of a given business decision.

Blockchain Increases the Transparency and Reliability of Transactions

You likely know blockchain by its most common application: cryptocurrency. But its relevance to manufacturers extends far beyond bitcoin.

In essence, the technology records data across multiple locations, linking a string of timestamped and irreversible “blocks.” Because changes to the data are permanent and visible across networks, blockchain technology produces a single verifiable record that all participants can reference simultaneously.

Manufacturers who implement blockchain into their ERP operations can create a dependable and detailed audit trail for materials, which in turn increases the reliability and security of your supply chain.

For instance, if a customer disputes the price or quantity of materials bought, both the supplier and end user can reference a shared ledger with total transparency. By accurately tracing a transaction for the entirety of the product’s life cycle, dispute resolution could eventually become a thing of the past.

CHALLENGES:

Because the technology is so new, small manufacturers could struggle with the lack of comprehensive application standards and insufficient legal/regulatory framework.

The market for scalable blockchain solutions is still immature, which could present significant challenges for growing small businesses.

OPPORTUNITIES:

Manufacturers who implement blockchain technology into their ERP system can increase the visibility and dependability of their supply chain operations.

Blockchain produces a shared and inalterable transactional history accessible to all parties, which will significantly reduce the need for dispute-resolution initiatives.

Priority: Unnecessary

In its current form, blockchain technology isn’t an ideal investment for most small and midsize businesses, lacking the maturity and dependability of more seasoned ERP technologies. Here’s what to consider before committing one way or the other:

Evaluate the nature and volume of your existing transaction disputes and whether implementing blockchain would alleviate them.

Gauge whether your business has a critical and immediate need for blockchain or if you can afford to wait until the technology matures.

Where to Go From Here

If one thing is certain, it’s that these ERP technologies—and manufacturing as a whole—will continue to evolve at breakneck speed. It’s therefore imperative that small manufacturers carefully consider the opportunities and challenges they present, and how they’ll affect their business, before implementation.

To recap:

Cloud computing is optional for SMBs, presenting more convenience and flexibility but lacking the functionality of on-premise systems.

Artificial intelligence is crucial, with many practical benefits that will become even more tangible in the next few years.

Big data is also crucial, giving your business unprecedented insight into virtually all business decisions.

Blockchain is unnecessary, at least until the technology develops and becomes more accessible to growing small businesses.

What else can you do to stay informed? For starters, if you’re in the market for a new ERP, you can research vendors on the Software Advice ERP product page and evaluate how each is integrating these technologies.

Or, if you’d like to talk to a real, live human, feel free to give one of our experienced software advisors a call at (855) 998-8505 for a free 15-minute phone consultation.

Note: The information contained in this article has been obtained from sources believed to be reliable. The applications selected are examples to show a feature in context, and are not intended as endorsements or recommendations.