Find the best Job Shop Software

Compare Products

Showing 1 - 20 of 50 products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Sponsored: Sorts listings by software vendors running active bidding campaigns, from the highest to lowest bid. Vendors who have paid for placement have a ‘Visit Website’ button, whereas unpaid vendors have a ‘Learn More’ button.

Avg Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

A to Z: Sorts listings by product name from A to Z.

Fishbowl

Fishbowl

Fishbowl is the #1 manufacturing and warehouse inventory management software! Its powerful inventory control system gives your small or midsize business the exact tools needed to transform your inventory management and scale your ...Read more about Fishbowl

Tangle

Tangle

Tangle is an open-source, low-code development solution that enables organizations to construct, design, and deploy enterprise-level applications. The platform provides various reusable components such as charts, tables, boards or...Read more about Tangle

REALTRAC

REALTRAC

Realtrac is an on-premise job management solution designed for job shop manufacturers and modular machine shops. It helps small and midsize manufacturers to schedule workflows, manage shop operations, track inventories, manage pur...Read more about REALTRAC

QT9 ERP

QT9 ERP

QT9 ERP is a highly-scalable manufacturing platform for connecting and automating business data from multiple systems into one scalable and intuitive solution. QT9 ERP integrates inventory management, accounting management, sales ...Read more about QT9 ERP

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Meet Eric, a software expert who has helped 1,534 companies select the right product for their needs.

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Tell us more about your business and an advisor will reach out with a list of software recommendations customized for your specific needs.

STEP 1 OF 4

How many employees are in your company?

Visual EstiTrack

Visual EstiTrack

Henning Software has helped small to midsize manufacturers and job shops for 30 years. Visual EstiTrack ERP has complete material requirements planning, product lifecycle, supply chain, customer relationship, human resource and ma...Read more about Visual EstiTrack

DELMIAworks

DELMIAworks

DELMIAworks (formerly IQMS) ERP is developed specifically for SMB and large discrete and batch process manufacturers in the aerospace, medical device, automotive, food and beverage, consumer products, plastics, packaging, and elec...Read more about DELMIAworks

Rootstock Manufacturing ERP

Rootstock Manufacturing ERP

Rootstock Software is a global provider of manufacturing cloud ERP on the next generation Salesforce Platform. It is purpose-built for mid-size discrete manufacturers who are looking to digitally transform on a future-proof platfo...Read more about Rootstock Manufacturing ERP

ShopKeeper Job Control

ShopKeeper Job Control

ShopKeeper Job Control is the flagship of the application suite that makes up the ShopKeeper ERP shop management solution for small- to mid-sized job shops, process shops and contract manufacturers. This solution has been refined ...Read more about ShopKeeper Job Control

Fulcrum

Fulcrum

Fulcrum is a cloud-based platform serving small/mid-sized manufacturers and job shops looking for a software platform that truly understands them and their unique, complicated processes. Humans weren’t meant to transcribe data fro...Read more about Fulcrum

MRPeasy

MRPeasy

MRPeasy is a versatile cloud-based ERP system for small and scaling companies (perfect for up to 200 employees). The software offers a complete ERP solution with robust production planning and inventory management functionalities ...Read more about MRPeasy

JobBOSS²

JobBOSS²

JobBOSS² helps job shops, make-to-order manufacturers, and contract manufacturers improve profitability and manage their supply chain. By integrating people, processes, and technology, our quote-to-cash solution reduces bottleneck...Read more about JobBOSS²

shopVOX

shopVOX

shopVOX is a cloud-based platform for small to large businesses, which helps automate and streamline all processes related to manufacturing of custom products. The centralized platform comes with job boards, which let users create...Read more about shopVOX

Statii

Statii

Statii software is a cloud-based system for small manufacturing companies. The solution is designed to facilitate communication between team members more effectively and manage activities involved in any manufacturing process. The...Read more about Statii

ProShop ERP

ProShop ERP

ProShop is a machine shop and manufacturing process management solution designed for small and midsize manufacturers. It offers enterprise resource planning (ERP), manufacturing execution system (MES) and quality management system...Read more about ProShop ERP

Fusion Operations

Fusion Operations

Fusion Operations by Autodesk is the SMB manufacturer’s gateway to digitization. It’s a complete, modular solution that gets any production environment ready for the future of manufacturing. Fusion Operations empowers SMBs with ...Read more about Fusion Operations

CyberPlan

CyberPlan

CyberPlan is the software that has enabled manufacturing companies to create optimized production plans for more than 30 years. It does this by anticipating unforeseen events, visualizing the causes of problems and simulating alte...Read more about CyberPlan

CADDi Drawer

CADDi Drawer

CADDi Drawer is an AI-driven drawing management software made to help manufacturers better leverage the historical data created through their processes. All aspects of drawings are automatically digitized and available for instant...Read more about CADDi Drawer

1factory

1factory

1factory is a quality management solution suitable for manufacturing companies of all sizes. Cloud-based and on-premise deployments are available. The solution offers quality control plans, first article inspections, incoming insp...Read more about 1factory

PolyPM

PolyPM

PolyPM was created by Polygon Software, a provider of technology solutions for apparel manufacturers and textile mills since 2001. PolyPM is a 2-in-1 enterprise resource planning (ERP) and product lifecycle management (PLM) solut...Read more about PolyPM

Infor VISUAL

Infor VISUAL

Infor VISUAL is an Enterprise Resource Planning (ERP) System with end-to-end functionality built for manufacturing organizations looking for a complete solution that supports the entire operational lifecycle, from planning to sour...Read more about Infor VISUAL

Popular Comparisons

Buyers Guide

Last Updated: March 16, 2023Job shop and machine shop specialties are limited-scale manufacturing, including prototyping and single unit production or “one offs.” Margins can be very thin, so successful firms balance their time spent on manufacturing with time on maintaining inventory and fostering customer relationships.

Job shop software is essentially an enterprise resource planning (ERP) system with a limited scope. In fact, it's is often part of ERP if the shop is a small part of a larger organization. Broadly speaking, the system is used to automate many of the tracking and scheduling duties within the company.

A prime requirement for job and machine shops is manufacturing resource planning (MRP), the system that schedules the manufacturing of each customer’s order. Inventory and order entry are important and must be integrated with the MRP system, particularly with the pipeline management system.

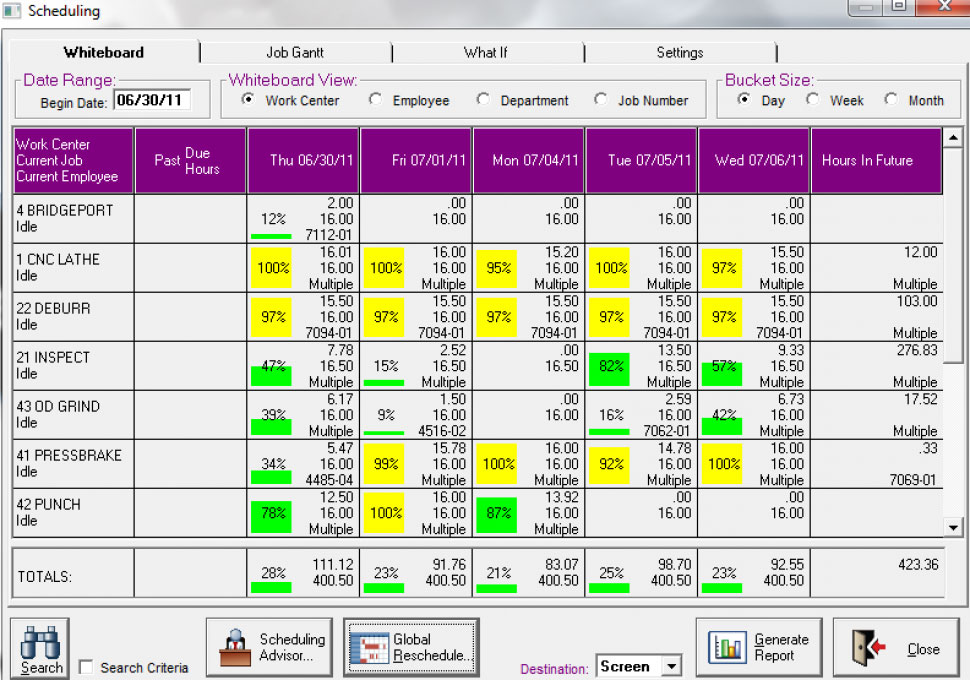

Screenshot of E2 Shop System scheduling whiteboard

Contract manufacturing is a relationship-based businesses. As such, owners should use customer relationship management (CRM) to track sales history and to market opportunities targeted at specific customers. Strictly speaking, payroll is standard. However, one of the resources tracked by MRP is worker time spent per work order. This allows owners and managers to measure the profitability of each employee.

General ledger, accounts payable and accounts receivable are standard. Most job shop manufacturing systems are installed on premises. The computerization and networking of tools and the associated costs means that most of the infrastructure to support job shop scheduling software is already in place, negating the hardware cost arguments for cloud-based installations.

Here's what we'll cover:

What Is Job and Machine Shop Software?

Common Features of Job and Machine Shop Software

What Is Job and Machine Shop Software?

Job and machine shop software provide necessary, real-time data that is related to manufacturing and other operations, such as job scheduling, finance, estimations, employees, sales, materials, engineering, job accounting and job management. They also provide job data related to competitors, vendors, customers, marketplace and the overall supply chain.

A job and machine shop solution helps manufacturing units reduce waste, enhance productivity and improve the bottom line. The solution helps users meet the specific requirements of job shops that cannot always be achieved using traditional manufacturing solutions.

Common Features of Job and Machine Shop Software

In addition to core business functions, it's important to evaluate the following functions to meet the company's unique requirements:

Pipeline management | Balances jobs against the available resources, checks inventory and prepares orders for materials. Advanced systems also factor in cost and price, prioritizing the most profitable production. |

Customer sales monitoring | Compares each customer’s historic sales to recent sales to gauge trends. Also, enables supports customer sales incentives. |

Job estimating | Evaluates required time, materials, machines and personnel to perform a job. Calculates costs and profit. Advance systems can substitute resources and optimize for time or profit. |

Make/buy reporting | Applies estimating to subassemblies to evaluate whether it’s more profitable to make or buy components. Advanced systems will factor in time to build or buy as well as cost. |

Process planning reporting | Helps plan and document each step in fabrication for accurate estimating and job tracking. The process planning reports track the development of the process plan for each contract. |

Material supplier planning | Assists in the make/buy process by helping material suppliers assign a bill of materials to each subassembly. Allows make/buy decisions to be based on current market prices for material and labor for each estimate. |

Fabrication scheduling | Supports dynamic scheduling fabrication process, changing as different jobs finish late or early and as materials arrive in inventory. Also allows schedules to be reprioritized. |

Customer delivery scheduling | Helps streamline flows of shipping/delivery/pick up for efficient fabrication process. Includes transit time and adjustable slack time. |

Slipped/late jobs reporting | Tracks and reports job status through the entire process from estimation to delivery. Advanced systems will have a dashboard that signals management as soon as a job slips past a defined threshold. |

Work load planning | Helps managers adjust the work load to leverage the most expensive equipment to depreciate or minimize usage of the most expensive to run. Also helps manage employee work loads, taking into account workers’ preferences. |

Scrap reporting | Provides efficient tracking to minimize the amount of scrap by planning production to make the most efficient use of material. Also helps tracks recyclable scrap through to resale to the scrap yard. |

Engineering change management | Tracks engineering changes and their impact on delivery date and profit on the project. It should also be easy to enter the changes into the system so that the changes can flow to other projects and the overall schedule. |

Market Trends to Understand

In the past several years, many major trends have influenced the manner in which job shops operate in the manufacturing sector, and will continue to impact in the future. New technologies, such as advanced robotics, data analytics and mobile devices will enable small job shops to compete with larger enterprises that have state-of-the-art infrastructure.

To keep up with the latest developments, job shops must be aware of the key trends:

Fully digital supply chain. The digitization of operations in a supply chain is about to become obligatory, leaving no scope for paper-based work. In this situation, paperwork is unacceptable in even the smallest of job shops. An all-digital supply chain increases productivity and efficiency and minimizes the chance of errors.

Artificial intelligence and predictive analytics. The back office requires a finer and better grasp of the big picture for uninterrupted operation. Many low-cost analytics platforms in the market quickly gather data in the warehouse, on the shop floor and through customer communications. This information is then assessed through predictive analytics to shape various supply orders for the upcoming months. It also helps predict which machine is likely to fail soon and which customers to pursue in the immediate term.

Augmented reality. A few years ago, the concept of augmented reality services, such as Google Glass, was in hype but it vanished quickly due to the high price of these services and devices. However, the concept has great potential. In the coming years, the cost of wearable hardware linked to such concepts is expected to reach a more realistic level. It will create plenty of opportunities in inventory management and enable quicker response to overall processes and operations on the job shop floor.