Find the best Production Scheduling Software

Compare Products

Showing 1 - 20 of 156 products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Sponsored: Sorts listings by software vendors running active bidding campaigns, from the highest to lowest bid. Vendors who have paid for placement have a ‘Visit Website’ button, whereas unpaid vendors have a ‘Learn More’ button.

Avg Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

A to Z: Sorts listings by product name from A to Z.

Evocon

Evocon

Evocon is an OEE (overall equipment effectiveness) solution designed to help businesses within the manufacturing industry to monitor production, track downtime, automate data collection from machines, and analyze performance in re...Read more about Evocon

MRPeasy

MRPeasy

MRPeasy is a versatile cloud-based ERP system for small and scaling companies (perfect for up to 200 employees). The software offers a complete ERP solution with robust production planning and inventory management functionalities ...Read more about MRPeasy

monday.com

monday.com

monday.com is an award-winning work and project management platform that helps teams of all sizes plan, prioritize, manage, and execute their work more effectively. The platform offers solutions for a wide range of use-cases such...Read more about monday.com

PolyPM

PolyPM

PolyPM was created by Polygon Software, a provider of technology solutions for apparel manufacturers and textile mills since 2001. PolyPM is a 2-in-1 enterprise resource planning (ERP) and product lifecycle management (PLM) solut...Read more about PolyPM

TotalControlPro

TotalControlPro

Streamline the manufacturing operations with cloud-based DynamxMFG SME Smart Manufacturing Platform. Whether for better control of inventory or better shop-floor visibility, there's a module designed for you. Analyze and adapt w...Read more about TotalControlPro

sedApta MOM

sedApta MOM

sedApta MOM is a manufacturing execution system (MES) designed to support your business with up-to-date, contextualized information. Our software enables stakeholders to optimize production scheduling and manufacturing operations ...Read more about sedApta MOM

L2L Connected Workforce Platform

L2L Connected Workforce Platform

L2L is the only Connected Workforce Platform that helps your shop floor workers manufacture better together. L2L has five modules that help manufacturers eliminate waste and maximize production throughput across their operations...Read more about L2L Connected Workforce Platform

NetSuite

NetSuite

With an integrated system that includes ERP, financials, commerce, inventory management, HR, PSA, supply chain management, CRM and more – NetSuite enables fast-growing businesses across all industries to work more effectively by a...Read more about NetSuite

NDS ERP Solutions

NDS ERP Solutions

NDS Systems provides enterprise resource planning (ERP) solutions for small to mid-sized organizations in the discrete manufacturing, wholesale distribution and fulfillment industries. It is built on Oracle platform which helps in...Read more about NDS ERP Solutions

Fishbowl

Fishbowl

Fishbowl is the #1 manufacturing and warehouse inventory management software! Its powerful inventory control system gives your small or midsize business the exact tools needed to transform your inventory management and scale your ...Read more about Fishbowl

DELMIAworks

DELMIAworks

DELMIAworks (formerly IQMS) ERP is developed specifically for SMB and large discrete and batch process manufacturers in the aerospace, medical device, automotive, food and beverage, consumer products, plastics, packaging, and elec...Read more about DELMIAworks

Visibility ERP

Visibility ERP

Visibility ERP is a fully integrated and modern ERP solution designed to meet the unique needs of manufacturers of complex products (including To-Order, ETO, CTO, MTO, Project Based, Discrete and Hybrid). It provides manufacturers...Read more about Visibility ERP

Visual EstiTrack

Visual EstiTrack

Henning Software has helped small to midsize manufacturers and job shops for 30 years. Visual EstiTrack ERP has complete material requirements planning, product lifecycle, supply chain, customer relationship, human resource and ma...Read more about Visual EstiTrack

MIE Trak Pro

MIE Trak Pro

One word sums up MIE Trak Pro: flexibility. You may be using tired old spreadsheets or an ERP system that can't scale with your manufacturing company. When your organization grows, MIE Trak Pro adapts to your needs, striking a bal...Read more about MIE Trak Pro

REALTRAC

REALTRAC

Realtrac is an on-premise job management solution designed for job shop manufacturers and modular machine shops. It helps small and midsize manufacturers to schedule workflows, manage shop operations, track inventories, manage pur...Read more about REALTRAC

JobPack

JobPack

JobPack offers a production planning and scheduling tool for shop floor control and materials management. JobPack is scalable and fits all sizes and disciplines of production manufacturing. JobPack manages every aspect of the...Read more about JobPack

Kinetic

Kinetic

Capture the true value of cloud ERP with Epicor Kinetic, a solution made with manufacturers, for manufacturers. An intuitive, configurable, and guided user experience with embedded learning helps you maximize your profitability wi...Read more about Kinetic

ProfitKey

ProfitKey

ProfitKey is an on-premise manufacturing management solution for small and midsize manufacturers and job shops. It caters to various manufacturing industries including aerospace, defence, automotive, capital equipment, electronics...Read more about ProfitKey

Statii

Statii

Statii software is a cloud-based system for small manufacturing companies. The solution is designed to facilitate communication between team members more effectively and manage activities involved in any manufacturing process. The...Read more about Statii

Deltek Costpoint

Deltek Costpoint

Deltek Costpoint is an enterprise resource planning (ERP) and management solution designed to meet the requirements of midsize and large enterprise businesses. The solution primarily assists government contractors, professional se...Read more about Deltek Costpoint

Popular Comparisons

Buyers Guide

Last Updated: March 16, 2023When standard manufacturing resource planning (MRP) tools are not powerful enough, production managers turn to more robust and more complicated, production planning and scheduling systems (aka “advanced planning & scheduling”). These best-of-breed planning systems use advanced mathematical models to better simulate the production environment. We wrote this buyer’s guide to help buyers unravel the web of manufacturing planning and scheduling solutions.

Here’s what we’ll cover:

What Is Manufacturing Production Planning and Scheduling Software?

What Is Manufacturing Production Planning and Scheduling Software?

“Theory is closer to practice in theory than in practice” is a truism in complex manufacturing. Manufacturing resource planning software is used by manufacturers to allocate raw materials and plan production. MRP works well for manufacturers that have large runs or few products. However, the planning methodologies used by most MRP applications cannot handle the demands of large numbers of small runs of products, orders that change frequently or large numbers of make-to-order (MTO) or customized products. That’s where manufacturing and planning scheduling software comes in.

Manufacturing scheduling software extends MRP in four important ways.

Instead of using total capacity as a baseline for each set of planning calculations, it uses available capacity. The difference is that MRP assumes that no other work is happening, while planning and scheduling systems constrains planning based on jobs that are already scheduled.

MRP uses simple formulas to project times to complete. Planning and scheduling solutions use more complex models, often running several different scenarios to create a more realistic simulation.

MRP tends to take stepped approach to ordering: materials are ordered, received, and then production begins. Planning and scheduling programs incorporate order lead time when planning the manufacturing planning process.

MRP does not consider the value of particular jobs. All jobs are treated equally. Manufacturing planning and scheduling systems, on the other hand, factors in the profitability of each of the jobs and prioritizes the most profitable jobs.

Manufacturing schedule software is best suited to operations that specialize in MTO or assemble to order (ATO) operations and in agile facilities. They are also useful for organizations that use a large number of components or have complex tasks. Finally, they are critical for firms that have a limited facility that is shared among different product lines that are competing for resources.

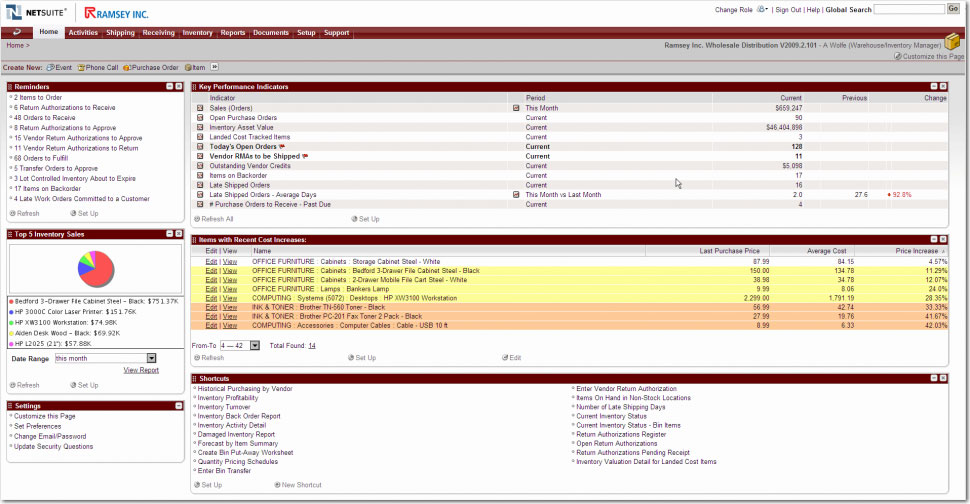

Inventory manager dashboard in Netsuite

What Type of Buyer Are You?

The first step in evaluating production planning software is to determine what kind of buyer you are. Over 90 percent of buyers fall into one of these three groups:

Enterprise resource planning suite buyer. These buyers value the seamless integration of data and processes that comes from having one system for all functions. For example, they would prefer a full-suite system for estimating, work-in-progress management and accounting that can automatically turn an estimate into a budget for project management, and then match invoices to project status and allocate job costs. These buyers favor ERP software vendors like Oracle, SAP, Sage ERP or Microsoft Dynamics.

Departmental buyer. These buyers work in facilities that are shared by product lines from different vendors. They are balancing demands from different product managers and must schedule production and justify the schedule to peers and management.

Small manufacturer. Small organizations often have limited budgets and fewer IT resources to dedicate to software. In many cases, they may be deciding between a new system and a new piece of equipment. These buyers need cost-effective solutions that are easy to implement and use. They are seeking solutions that maximize the profitability of their plant or job shop.

Common Functionality

Production planning and scheduling software is highly complex, and different vendors specialize in various areas of niche functionality. The following table, however, shows the core features of this software category:

Finite capacity scheduling | Complex algorithms allow you to forecast the completion of jobs based on limitations on resources, instead of scheduling jobs without regard to such constraints. |

Gantt charts | Gantt charts display resource utilization. |

Live capacity planning | Instead of determining the production schedule in advance, which can result in bottlenecks, you can adjust the schedule in real time as issues occur. |

Visual, drag-and-drop scheduling | You can easily get a visual overview of the production scheduling. New work orders can be dragged and dropped into the schedule, which updates the overall production schedule. |

Multiple scheduling priorities | You can assign different priority levels to individual jobs/orders when setting the production schedule. |

“What if” scenario modeling | Manufacturing production planning and scheduling software supports forecasting via multiple “what-if” scenarios. |

Benefits and Potential Issues

MRP systems, whether stand-alone or incorporated in an ERP system, offer distinct benefits over less formal systems. These include:

Better use of equipment. Manufacturing planning and scheduling systems increase company utilization of equipment. For example, the system can prioritize the use of the most expensive equipment to lower that equipment’s cost per project or can prioritize the less expensive equipment to decrease costs across jobs.

Increased profitability. The combination of increasing utilization and prioritizing the more profitable jobs leads to increased profitability.

Identifying bottlenecks. Planning and scheduling systems can identify bottlenecks and their associated procedures or equipment, giving managers an opportunity to boost productivity even further by adding machines or updating methodologies.

One of the biggest issues that arrive from using production planning and scheduling systems is the tendency for managers to “tweak” the system’s recommendations. This can lead to suboptimal results. If the planning and scheduling system continually gives information with which the manager disagrees, the assumptions must be re-examined or the manager should receive additional training.

Market Trends to Understand

While you evaluate production planning and scheduling systems, make sure you consider these market trends:

Convergence with MRP. As the power of desktop computing continues to grow, traditional MRP systems are adding advance planning functions to their toolkits. Planning algorithms that were once only found in high-end planning systems are now in more moderately priced MRP or ERP systems.

Direct interface with shop floor equipment. Some planning and scheduling systems can get utilization information from equipment, either directly or through the manufacturing execution system. This provides two advantages, the information is more current and it does not have to be entered by hand.

Increased employee satisfaction. Production planning systems can consider employee preferences when allocating resources to a job, allowing employees to work preferred hours or on preferred jobs.

Planning using data visualization. Traditional MRP systems produce reports and planning schedules. Manufacturing planning and scheduling systems do, too, but they are also beginning to offer other visualization tools, such as graphical comparisons of the results of different models.