Dinner Is Conserved: 4 Ways ERP Software Helps Reduce Food Waste

Here’s some food for thought: Americans throw out 150,000 tons of food each day, good for about a pound per person. This accounts for roughly a third of the nation’s total food supply, and a cumulative cost of $160 billion annually.

But this isn’t simply a consumer problem—food waste in restaurants amounts to 11.4 million tons each year, while manufacturers and distributors have a responsibility to move their products through the supply chain as efficiently as possible.

Here’s the good news: ERP software helps businesses do exactly that.

Food and beverage companies that use the inventory tracking and supply chain components of an ERP system to manage acquisition, shelf life and distribution of perishable goods will reduce food waste by as much as 50 percent.

Here’s how ERP software helps businesses:

Simplify Inventory Tracking and Shelf Life Management

Increase Logistical Efficiency and Productivity

Ensure Food Quality Meets Organizational and Regulatory Standards

Eliminate Guesswork With Advanced Reporting and Dashboards

Simplify Inventory Tracking and Shelf Life Management

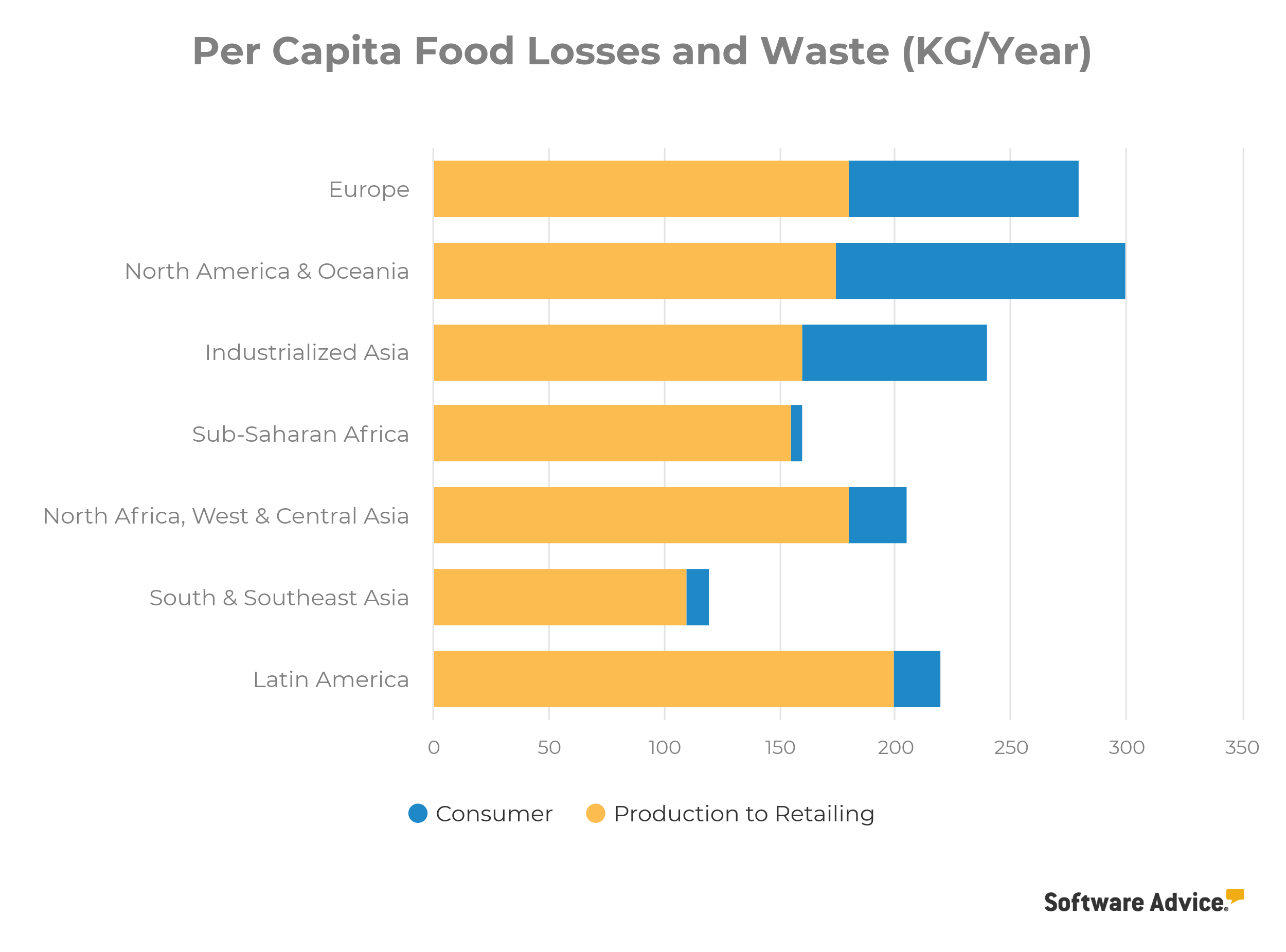

According to a study by the Food and Agriculture Organization of the United Nations, roughly a third of all food produced for human consumption is lost or wasted, and North America is responsible for more aggregate food waste than any other region.

(Source)

It’s easy to look at these numbers and lay blame at the feet of North American consumers, who bear more responsibility than those in other parts of the world. But the sooner producers and distributors get perishable goods into the hands (and mouths) of individuals, the less likely it is that these foods will go to waste.

How ERP software helps: With ERP software’s inventory tracking component, businesses can simplify the process of monitoring goods as they move through the supply chain, in turn reducing production time and increasing the shelf life of perishable foods.

Food and beverage companies can track what’s currently in stock, how long until each food item expires, where it was sourced from and which quality standards to comply with. This not only ensures an optimal product, it also allows for the expedition of items lagging behind in the supply chain—so you’re never taken aback by spoiled, inedible food.

For example, a restaurant can track an avocado from when it’s produced, ordered and delivered to the moment it lands on a plate, with the added luxury of being able to reorganize inventory based on the optimal consumption date. Great for business, even better for avocado-loving consumers.

Increase Logistical Efficiency and Productivity

One of the greatest challenges facing manufacturers—especially those with a diverse product offering—is keeping their stock levels organized in a transparent way.

Market research firm IDC found that businesses lose 20 to 30 percent in revenue each year due to workflow inefficiencies, and those in the perishable goods business have even less margin for error: Historically speaking, the food and beverage industry is notorious for high costs and low profit margins, and nothing says “waste” more than an uneven logistics process.

But with the recent proliferation of a concept known as lean manufacturing, businesses that deal with perishables are rightfully focused on becoming leaner, more efficient organizations across the board. And what better way to streamline your business than with ERP software?

How ERP software helps: ERP systems can automate routine tasks and streamline processes in a way that impacts the entirety of the organization. Whether it’s managing finances, processing orders or onboarding new employees, the software consolidates a variety of business functions into a unified whole and allows disparate systems to communicate with each other.

These efficiency boosts trickle down to waste reduction, too. By streamlining inventory records and automating routine processes, ERP software frees up the vital resources businesses need to harvest the optimum product—and do it with maximum efficiency.

For example, a bottling plant could use AI and generative design to produce the most cost-effective product blueprint, identify gaps in the materials acquisition and even calculate any potential cost savings before implementing any changes.

If that weren’t enough, ERP’s shrewd workflow management and subsequent productivity boost means the company can dedicate resources to cost-saving measures like waste reduction—yet another benefit of a more methodical and data-focused supply chain.

Ensure Food Quality Meets Organizational and Regulatory Standards

Not all shelf lives are created equal; there’s less urgency to move, say, a can of corn through the supply chain than an ear of corn.

With varying shelf lives and even more variance in acquisition dates, even the most disciplined manufacturer can get overwhelmed in a hurry. But to get a comprehensive glimpse into the health of a given food item, it’s imperative that you routinely monitor its quality level.

How ERP software helps: With an ERP, food and beverage companies can establish food quality benchmarks and standardized assessments to guarantee the desired quality is met as it moves through each stage of the supply chain. A business can then ensure items that don’t meet the appropriate level of quality or freshness aren’t distributed until they pass the smell test.

What’s more, ERP’s lot tracing functionality makes it easier for businesses to adhere to ever-changing Food and Drug Administration regulations, and even produce certificates documenting their compliance. So if there’s any doubt about your ERP’s effectiveness, the proof will be in the pudding—literally, for those in the pudding business.

For example, if said pudding manufacturer used its ERP to maintain a log of regulatory changes and internal inspection records, they’d always have access to the most current data available.

An inspector could be on the factory floor, queue up the ERP app on their smartphone and pinpoint the precise regulatory statute they need to adhere to. They could then update the log remotely and someone else in the corporate office would see the changes in real time.

Eliminate Guesswork With Advanced Reporting and Dashboards

There’s no greater obstacle for food and beverage companies than demand planning. Seasonality, geography, product launches, regulations, perishability—it’s staggering how many variables manufacturers need to consider when sourcing materials. So how can a business anticipate—with precision—the right amount of goods without over- or undershooting it?

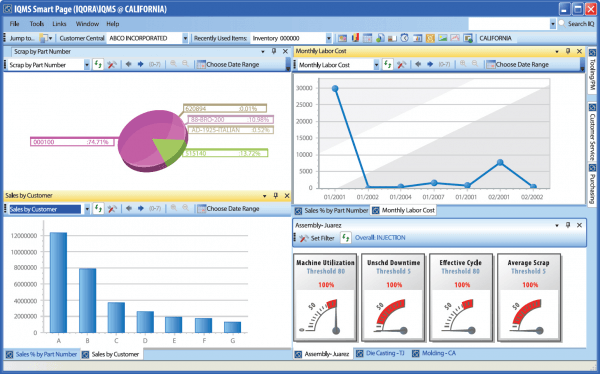

The solution, of course, lies in ERP software’s advanced reporting functionality, with the unique ability to forecast demand down to the last can of soda. ERP dashboards are critical to the success of nearly every demand-driven business—especially those in the food and beverage industry.

An ERP dashboard in IQMS (Source)

How ERP software helps: By merging historical sales data with advanced analytics, ERP dashboards integrate a treasure trove of data points—including seasonality, location and even individual clients—to forecast demand with unprecedented accuracy. And it’s all presented in an aesthetically pleasing, easy-to-decipher visual.

On the other side of the planning coin, an ERP’s supply forecasting component weighs factors like lead times and materials’ availability to optimize inventory levels and continually improve the procurement process. A surplus of perishable materials often means a mountain of food waste, but ERP software gives food and beverage manufacturers the tools they need to replenish their supply with maximum efficiency.

For example, a seafood restaurant can use an ERP to not only track how many salmon filets they have on hand, but also anticipate how much they’ll need to source during peak demand months, what it’ll cost to procure just the right volume and the date it’ll be delivered. We’ve never been closer to actually predicting the future.

Reduce Food Waste Right Now With These Next Steps

Identifying and deploying a new ERP is a months-long process that requires thorough, exhaustive preparation. So if you’re exploring the possibility, there are things you can do right now to get the proverbial ball rolling.

Conduct a food waste audit. The first and most logical step is to determine exactly how much food you’re throwing out. If you aren’t already, ask your staff to keep a log of what’s being discarded, the reasons for tossing it and the exact amount thrown away.

Once you have a foundation of data to work with, you can extrapolate yearly projections and calculate the financial cost and how much you could save with an ERP system. Buying and implementing ERP software is a significant investment, so identifying potential savings is central to convincing those who will have the final say.

Research [food and beverage-focused ERP systems](https://www.softwareadvice.com/erp/). Whether it’s an all-in-one “best of breed” system or individual components, many vendors offer solutions geared specifically toward food and beverage companies. Every food and beverage company is different, and no one-size-fits-all approach exists, but the perfect ERP solution is out there for the taking.

And to find it, you’ll need to determine exactly what you need and how it fits into the framework of your business. You can start by visiting our ERP software page, which hosts a list of more than 150 vendors and customizable filters—so you can find the software that best suits your needs.

Give us a call. Still not sure what you’re looking for? Our team of friendly software advisors is an invaluable resource for any business exploring its options. Our 15-minute phone consultations are free of charge, complete with a detailed needs assessment and a list of products we recommend. Call us at (855) 998-8505—time’s a-wastin’.