MRP vs. MRP II: What's the Difference?

The world of manufacturing software includes several less-than-helpful acronyms to describe the variety of products with distinct, production-oriented functionality.

So, if you’re in the market for an MRP system, it’s important to distinguish between MRP I and MRP II software.

Select the right option between Material Requirements Planning (sometimes referred to as MRP or MRP I) and Manufacturing Resource Planning (known as MRP II) or else risk adopting a system that either doesn’t drives your goals or one that breaks your budget.

But what’s the difference when it comes to MRP I vs. MRP II?

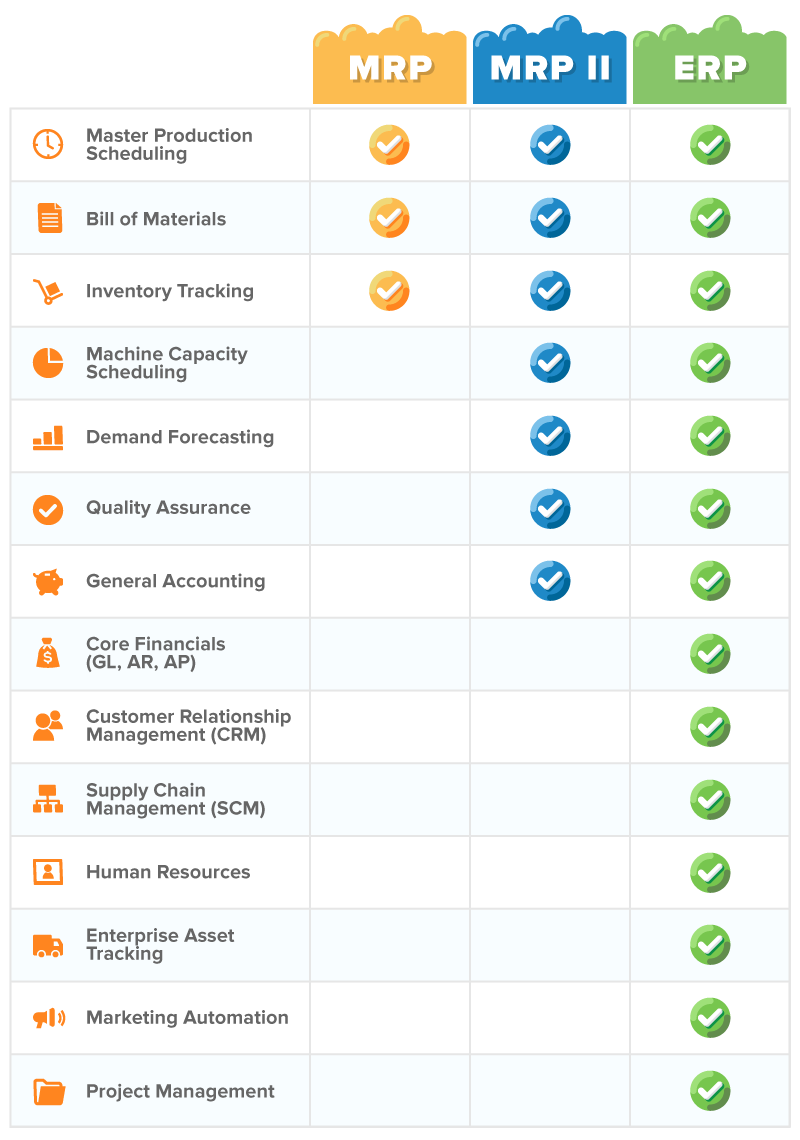

In short: MRP II (the successor to MRP I) includes the same core scheduling tools and inventory management, but adds functionality to forecast demand, manage capacity, boost quality and more.

Where Did MRP II Come From?

MRP I was some of the first business software to be widely adopted during the 1970s. Manufacturers sought these systems in order to improve efficiency and accuracy when it came to basic processes such as production scheduling and inventory management.

By the 1980s, manufacturers realized they needed software that could also tie into their accounting systems and forecast inventory requirements. Enter MRP II, which included these integrations in addition to all the capabilities offered by MRP I. Enterprise resource planning (ERP) software features—which we’ll cover later on—are included in the following table for comparison.

Can I Still Buy MRP I Software?

These days, you would be hard-pressed to find manufacturing software that’s strictly limited to basic material requirements planning. Most manufacturing software vendors offer a much greater depth of functionality, often tailored for specific industry niches such as food manufacturing or chemical processing.

Some smaller manufacturers might still rely on legacy MRP I software, or use a homegrown system that covers basic MRP I functionality. For all intents and purposes, though, MRP II has effectively replaced MRP I software. Indeed, most manufacturers can benefit tremendously from the added functionality MRP II systems offer.

Do I Need ERP Software?

If you’re still looking into MRP vs. MRP II software, it might be time to look to ERP systems, which are regarded as the successors to MRP II software. ERP suites include applications that are well outside the scope of manufacturing. These can include everything from human resources and customer relationship management to enterprise asset management.

For some smaller manufacturers, a heavy-duty ERP system might be overkill—but for larger manufacturers, an ERP suite is absolutely essential.

Larger manufacturers typically have a lot of moving parts within their organizations. Thus, they can greatly benefit from a fully integrated system that not only provides deep visibility into manufacturing processes, but also supports important aspects of running a business.

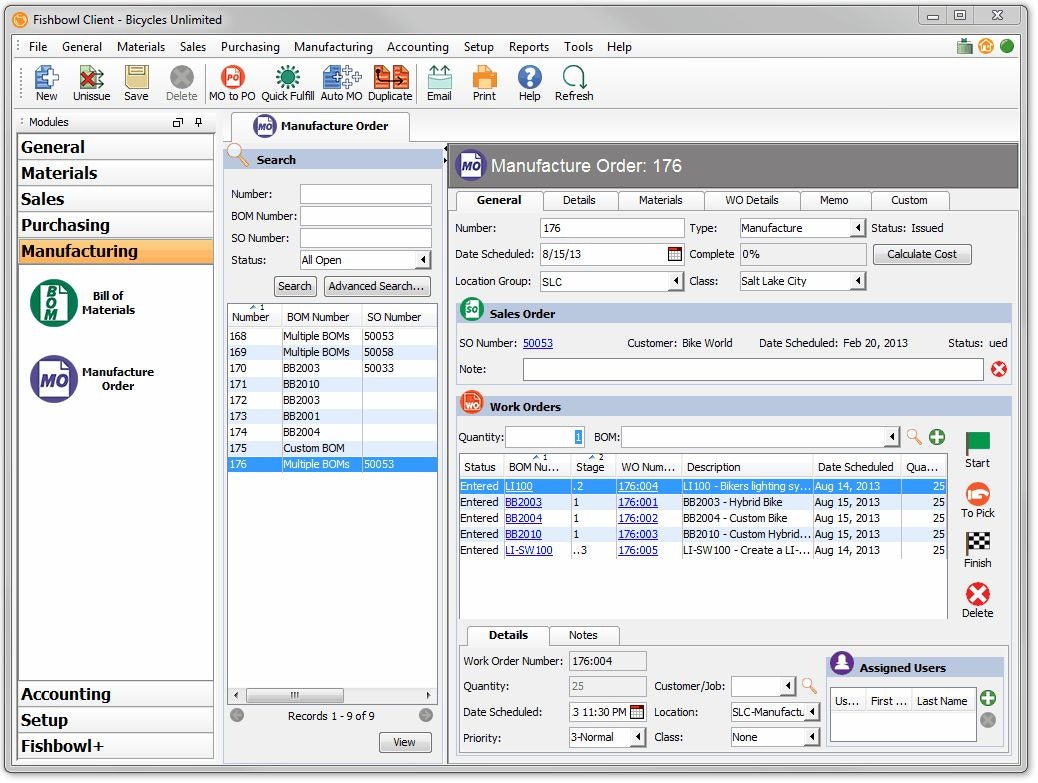

For example, Fishbowl Manufacturing or E2 Shop System are scalable for smaller manufacturers not ready to upgrade to a heavy-duty ERP suite.

Both include MRP modules, and support accounting functionality through QuickBooks integration.

Manufacture order in Fishbowl Manufacturing (Source)

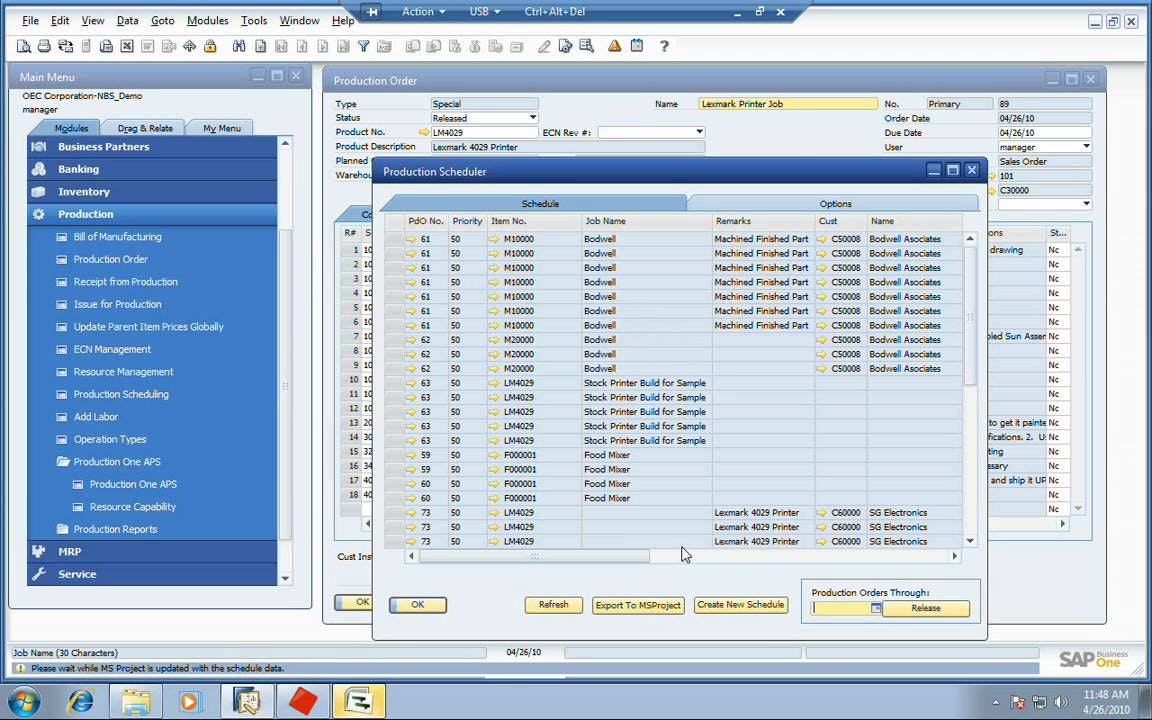

Conversely, a larger manufacturer would be much better served by an advanced ERP suite. Many of these manufacturers rely on systems provided by mega-vendors such as SAP and Epicor.

SAP Production Scheduler module (Source)

For instance, these offer more advanced scheduling and production capabilities with its system. These are essential for large manufacturers that produce a wide variety of items and have to coordinate with many suppliers and distributors.

I’m Ready to Evaluate Manufacturing Software

With a new understanding of the manufacturing software landscape, you can choose an MRP II, ERP or other product based on your production setup and goals.

If an MRP II system is what you need to optimize your materials and scheduling, review the top MRP II products.

Maybe you’re ready to implement an ERP to get a wider view of your business—check out our ERP systems.

Still not sure what type of software you need for your manufacturing firm? Call our Software Advisors at (844) 680-2046 for a free, 15-minute consultation and receive a personalized shortlist of vendors

Note: The applications selected in this article are examples to show a feature in context and are not intended as endorsements or recommendations. They have been obtained from sources believed to be reliable at the time of publication.