What Is Digital Twin Technology, and How Do You Ready Your Business for It?

A high-level management meeting was underway at a company to discuss the unplanned shutdown of one of its manufacturing units due to the breakdown of a hydraulic pump.

The procurement manager rushed in saying, “I’m sorry I’m late! But I just placed the order for a new pump. And we are getting twins!”

The team looked baffled. “Twins?”

“Yes! Twins! One is the physical entity, and the other is its digital sister—the digital twin.”

What is a digital twin?

A digital twin is an electronic replica of a physical entity, such as a thing, process, or person. It includes details about size, components, performance, etc. and stores current and past data about the object, captured using sensors and actuators. This data is fed into analytical models to generate valuable insights.

In this article, we’ll discuss various aspects of digital twin technology and the benefits your business can reap from it.

Here’s what we’ll cover:

Benefits of digital twin technology

Procurement options for a digital twin model

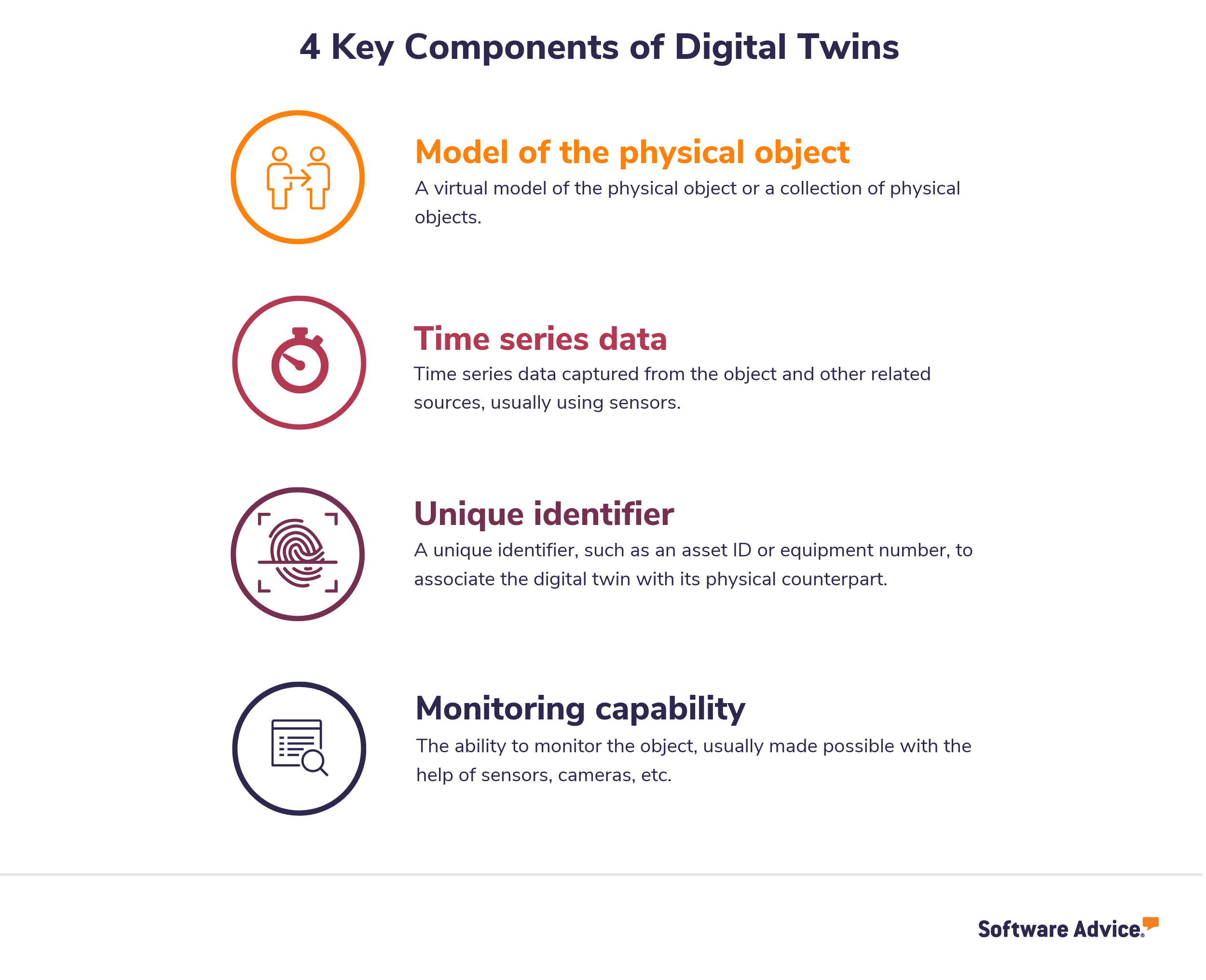

Components of digital twins

Internet of things (IoT), machine learning, artificial intelligence (AI), and big data are the technologies enabling digital twins. A digital twin need not always be a 3D replica of the actual object (though a 3D model is highly desirable). Let’s have a look at the four key components of a digital twin.

Types of digital twins

Depending on what they replicate, digital twins can be classified into the following types:

Discrete digital twins: Virtual replicas of individual products/equipment, persons, or tasks to help monitor and optimize the performance of individual assets, people, and other physical resources.

Composite digital twins: They help monitor and optimize the use of a combination of related discrete digital twins—e.g., virtual models of multipart systems, such as cars and industrial machines.

Digital twins of organizations (DTOs): DTOs are virtual models of complex and large entities (e.g., an entire organization or a city), composed of the digital twins of their constituent parts. They help monitor and optimize higher-order business performance.

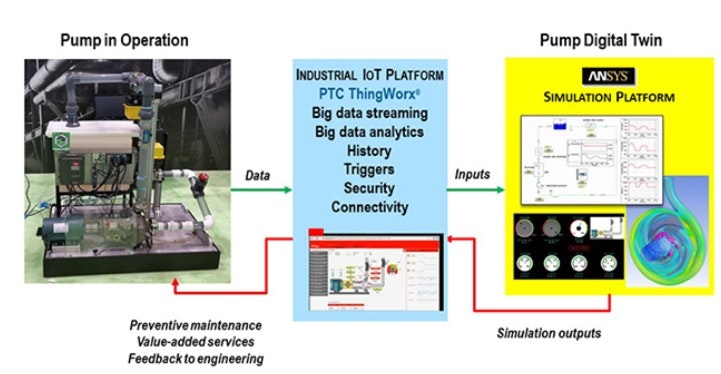

Flowchart depicting how a digital twin pump is connected to its physical counterpart (Source)

Flowchart depicting how a digital twin pump is connected to its physical counterpart (Source)

Use cases of digital twins

In this section, we’ll discuss the application of digital twin technology in various industries.

Manufacturing: Real-time analysis of the functioning of machinery using their digital twin helps reduce maintenance costs and optimize production output. General Electric Co. had over 1.2 million digital twins as of September 2018.

Automobile: Virtual replicas of vehicles collect behavioral and operational data of their physical counterparts to help analyze and improve vehicle performance. They also assist in developing and testing new product models, including hybrid and electric vehicles.

Construction: Digital twin models of buildings collect real-time data about the structure via sensors and other wireless technologies. They help improve the design and quality of construction projects as well as reduce maintenance costs.

Aerospace and defense: Digital twins are used for improving product designs and performance. The National Aeronautics and Space Administration (NASA) uses digital twins to operate, maintain, and repair systems located in outer space. The U.S. military uses digital twins to validate the integrity of the chips and semiconductors used in its weaponry.

Sports: Sensors and analytics help create virtual representations of athletes and simulate game situations to identify most likely injuries and improve performance. Formula One racing teams use digital twins to analyze adjustments that can improve the performance of their cars.

Healthcare: The digital twin of a patient or an organ allows doctors to practice procedures in a simulated environment. Digital twins are also used to conduct virtual clinical trials before rolling out new drugs or vaccines.

Benefits of digital twin technology

There are many benefits of using digital twins for your business. Let’s have a look at a few.

Reduces product quality issues: Digital twins simulate different “what-if” real-world scenarios to help businesses understand possible effects, improve operations and processes, and identify product quality issues, if any.

Lowers maintenance costs: Digital twins predict maintenance failures via simulation models that capture information about various risk factors, operating scenarios, and system configurations. They help save costs, improve equipment reliability, reduce downtime, and extend the equipment life span.

Improves employee training: Digital twins can recreate real-life hazardous situations to train employees. Employees can be also trained to handle equipment that isn’t physically close or is too costly to be given hands-on training.

Enhances efficiency and productivity: Using digital twins, businesses no longer need to experiment with physical objects to improve processes. They don’t need to halt ongoing processes and can simply run simulations in the lab to understand the risks and benefits of new processes, and keep tinkering with them to see which adjustments offer the best results.

3 procurement options for a digital twin model

In this section, we’ll discuss the different ways in which you can procure or build a digital twin.

1. Digital twin enabled-applications

In this model, digital twins are delivered along with business applications or IoT-connected products and equipment. This is the easiest, quickest, and least expensive way to procure a digital twin. As per Gartner’s report Market Guide for Digital Twin Portfolios and Enabling Technologies (full content available to Gartner clients only), 50% of businesses use this method to procure digital twins. Digital twins are increasingly being offered as a feature of business applications, such as asset performance management and field service management.

Vendors: GE Digital, Oracle, IBM, SAP, and Bentley Systems

2. Custom built

You can use in-house talent and technology, such as IoT platforms, analytics and simulation tools, and business process management (BPM) software, to design and deploy digital twins. Alternatively, you can outsource the development of digital twins to IoT vendors or IT service providers. Custom-built digital twins help meet your specific and unique needs, but they involve high costs and a long deployment time.

Digital twin-enabling tech providers: Accenture, Atos, IBM, Microsoft, and Mavim

3. Commercial off-the-shelf (COTS) digital twin templates

These are offered as software packages by technology service providers and original equipment manufacturers to meet specific IoT use cases. COTS digital twin templates vary in completeness, cost, and deployment approach as per the provider. They are generally configured to support a particular use case (wind turbines, elevators, car engines, etc.). These are easier and faster to incorporate than digital twins developed in-house but are relatively immature and can pose integration and security challenges.

Vendors: ANSYS, SAP, GE Digital, Uptake, and Hitachi

How to prepare your business?

Creating a digital twin requires prior groundwork. Our checklist highlights the key things you must have in place for your digital twin investment to pay off.

Remember that digital twins are still an emerging technology, so test the waters prudently. Here are a few recommendations that you should follow:

Earmark a budget for testing digital twins and other related technologies, and don’t exceed it.

Experiment in areas that already have successful use cases.

Read more, and train yourself on technologies needed to lay the groundwork for digital twins.

Reach out to IT experts and consultants to discuss your interest in exploring digital twin technology.

Note: The information contained in this article has been obtained from sources believed to be reliable. It isn’t intended as an endorsement or a recommendation by Software Advice.