Find the best Tool Management Software

Compare Products

Showing 1 - 20 of 58 products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Sponsored: Sorts listings by software vendors running active bidding campaigns, from the highest to lowest bid. Vendors who have paid for placement have a ‘Visit Website’ button, whereas unpaid vendors have a ‘Learn More’ button.

Avg Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

A to Z: Sorts listings by product name from A to Z.

Reftab

Reftab

Designed for schools and IT departments of any size, Reftab is a free asset management solution that helps administrators track and manage inventory, conduct asset maintenance, and complete work orders. With Reftab's intuitive dra...Read more about Reftab

EZOfficeInventory

EZOfficeInventory

EZOfficeInventory is a dynamic asset and maintenance management solution tailored for companies of all sizes. The cloud-based software works as you do and is accessible from anywhere and at any time. Track items across locati...Read more about EZOfficeInventory

eMaint CMMS

eMaint CMMS

Cloud-based eMaint CMMS software by Fluke enables maintenance professionals to monitor, capture, store, and share historical asset performance data and use it to maintain and prolong equipment life. Small or growing organizations ...Read more about eMaint CMMS

MPulse

MPulse

MPulse Software doesn’t sell “basic” maintenance management software, because we know that even smaller organizations need robust software to manage the increasingly complex demands of modern maintenance management. Whether you ch...Read more about MPulse

MicroMain

MicroMain

MicroMain CMMS/EAM software is a powerful, flexible, & easy-to-use maintenance management software. The software gives you the tools to streamline maintenance operations, maximize productivity, and reduce costs. The platform is ea...Read more about MicroMain

FMX

FMX

FMX offers configurable maintenance and facilities management software that helps organizations maximize productivity, cut operating costs, and gain actionable insights about their equipment and facilities. The software decreases ...Read more about FMX

FTMaintenance Select

FTMaintenance Select

FTMaintenance is on-premise computerized maintenance management system (CMMS) that enables maintenance professionals to easily document, manage, and track maintenance activities in order to reduce operational downtime, lower maint...Read more about FTMaintenance Select

Fiix

Fiix

Fiix is a cloud-based computerized maintenance management system (CMMS) that helps businesses organize their maintenance departments, get on top of maintenance backlog, and work towards preventive maintenance. The CMMS helps man...Read more about Fiix

Limble CMMS

Limble CMMS

A maintenance solution simple enough that even your boss will use it. Our average customer reduces downtime by 32%, increases productivity by 26%, reduces part spend by 23% and increases asset life by 18%. All of this within a m...Read more about Limble CMMS

Asset Essentials

Asset Essentials

Asset Essentials by Brightly Software (formerly Dude Solutions) is a next-generation work and asset management platform designed for smarter, more efficient maintenance and operations. Brightly, now a Siemens company, is the globa...Read more about Asset Essentials

Tenna

Tenna

Tenna is a construction technology platform that revolutionizes equipment fleet operations. It lets you know more, with reliable tracking and a unified platform for mixed fleets, built on over 100 years of construction experience....Read more about Tenna

Construction Tool Tracking System

Construction Tool Tracking System

ShareMyToolbox is a mobile construction tool tracking solution that allows contractors to use their own mobile devices to track construction tools and equipment. Administrators can easily build a catalog of construction equipment ...Read more about Construction Tool Tracking System

ON!Track

ON!Track

Hilti's ON!Track solution was specifically designed to help solve problems related to managing your assets, services, workers, and safety certifications. Quickly check your inventory and track your tools and equipment. Manage your...Read more about ON!Track

Align

Align

Align (formerly ToolWatch) is the construction industry’s first and most comprehensive operations management platform. For 30 years, Align has helped leaders from construction across the globe manage their equipment, tools and mat...Read more about Align

Asset Panda

Asset Panda

Asset Panda is a cloud-based platform for facility managers that offers a suite of applications including asset tracking and maintenance management. It is compatible with Windows, Mac, iPad, iPhone and can be used from anywhere wh...Read more about Asset Panda

Tego

Tego

Tego provides an asset tracking system, ideal for distributed workforce and assets on the move. Seamlessly deployed and powered by Tego's Asset Intelligence Platform (AIP), it provides asset owners, operators, and maintenance pers...Read more about Tego

Redlist

Redlist

Redlist helps companies make maintenance management work easier and more productive. Redlist is a mobile-ready, cloud-based software-as-a-service (SaaS) platform accessible on computers and handheld devices. Redlist also includes...Read more about Redlist

IntelliTrack

IntelliTrack

IntelliTrack Assets helps businesses maintain and track various assets including technology, furniture, tools, off-site equipment, and more. The platform enables organizations to monitor asset movement, maintenance schedules, assi...Read more about IntelliTrack

AssetTiger

AssetTiger

AssetTiger is a cloud-based asset management software designed to help businesses streamline processes related to maintenance scheduling, barcode scanning, expiration tracking and more. Administrators can add multiple users on the...Read more about AssetTiger

ArcGIS

ArcGIS

ArcGIS is a mapping and analytics solution that helps businesses in healthcare, banking, manufacturing and other industries manage field operations, data collection, visualization, workflow configuration and more. Field workers ca...Read more about ArcGIS

Buyers Guide

Last Updated: March 16, 2023A typical maintenance department must track dozens, or even hundreds, of different assets that need testing, repairing and replacing. Each of these tasks requires the use of specific tools that are critical to completing a job appropriately and on time.

But what happens when an electrical technician arrives to a job site without a multimeter or wire stripper? How can a worker frame a new house without clamps or an air compressor?

Workers shouldn’t have to waste time searching for the right tool, and lost or stolen equipment halts progress and eats into a company’s profits.

Tool tracking and management with a computerized maintenance management system (CMMS), enterprise asset management system (EAM) or a stand-alone inventory solution can keep your important tools and equipment organized, so technicians can find what they need quickly, saving both time and money. And if something goes missing, you’ll know immediately and can address the problem as soon as possible.

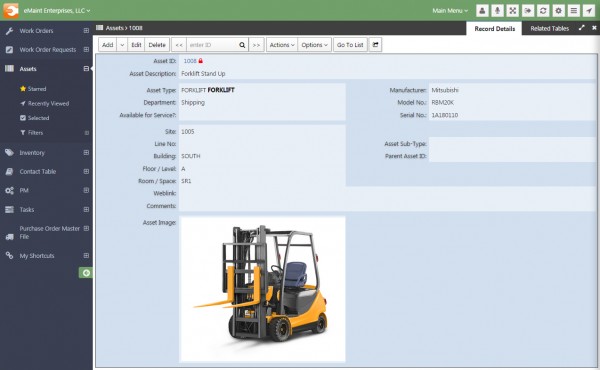

An equipment profile in eMaint CMMS showing location and other details

This guide is designed to show how you can use software to track the tools that keep your operations moving.

Here’s what we’ll cover:

Benefits of Tool Management Systems

Computerized Maintenance Management Software BuyerView 2014

What Is Tool Management?

Maintenance teams, contractors, electricians, field technicians and other professionals store their tools in boxes and larger equipment in a toolroom or tool crib. A failure to organize tools and equipment slows down work and reduces productivity.

Tool management is a smart choice for asset-intensive industries, such as:

Manufacturers

Maintenance departments

Field service organizations

Emergency services

Law enforcement

Schools and universities

These organizations track assets such as AC units, vehicles, heavy equipment or lighting, i.e., items needed to make the company money. So why shouldn’t tools be tracked the same way?

This is where tool management software, also referred to as tool tracking software, can help. Often a function of inventory management, a tool management system allows organizations to create a profile for each tool, complete with images, history and current location or user.

These systems can also offer more advanced functionality, including:

Barcoding. Just like other assets, tools and equipment can be assigned a unique barcode or QR code. Using the camera on a mobile device, technicians can scan a tool to retrieve its system profile and edit or add information.

Reservations. If a maintenance team has five multimeters, managers should know where each one is at all times. By assigning a code to each particular asset, workers can reserve tools to ensure they can complete their tasks correctly and on time. In addition, this functionality helps teams reduce losses and tracks which employee reserved the tool last to increase accountability.

Reporting. Have you ever asked yourself: “How old is this air compressor?” Or, “Who uses this mixer most often?” Or perhaps, “How much are we spending on storing these tools?” Without a system serving as a repository of historical data about tools and assets, these questions are likely to go unanswered. Reporting capabilities allow you to generate reports on various inventory or equipment metrics to identify areas for improvement.

Next, we’ll learn about some key benefits of managing tools.

Benefits of Tool Management Systems

Because tool management software is related to inventory management software, the benefits are similar. Here are some of the key benefits:

Increased oversight and collaboration | As a result of detailed usage data, you can create reports and identify problem areas, and share this data among departments. This way, other business units can make more strategic decisions based on real-time availability of equipment. |

Reduced equipment losses | A system that keeps track of equipment helps reduce losses that can cost companies thousands of dollars to replace a machine or in productivity. |

Improved workflows | For organizations that maintain equipment, mobile devices are especially beneficial. Workflows are streamlined—technicians can view the location of tools and reserve them, all from their smartphones, and the system updates in real-time. |

Barcodes Versus RFID

Asset management can be simplified with tagging, which allows quick identification of equipment by scanning a tag with a mobile device.

Two common methods prevail today: barcodes and radio frequency identification (RFID). Each option has pros and cons, so here are some details to help you determine which works best for your tool tracking needs:

Barcodes. You’re familiar with these—the vertical black lines found on every consumer product that can be quickly scanned. Barcoding is:

Less expensive

Easier to place on nearly any surface

Scannable with most smart devices

RFID tags. These new types of tags contain microchips that store data and can be attached like a sticker to individual tools. RFID tags:

Can hold a lot of data within the microchip

Don’t require direct line of sight to scan

Are typically more durable

Keep in mind that RFID tagging is often a more complicated implementation, but offers more advanced capabilities, such as scanning multiple tags at once to get information about an entire group of assets or tools.

If you manage simple tools, barcoding can offer an affordable, easy-to-use method. For more complex tools that have difficult-to-access internal components, RFID tags can make finding tool information easier.

Computerized Maintenance Management Software BuyerView 2014

At Software Advice, we speak with hundreds of software buyers each year. Through these interactions, we identify common pain points and requested features for each type of software. We used the gathered data to create a BuyerView.

We found that preventive maintenance is the top-requested feature in a maintenance system at 25 percent, likely because this is a task that is difficult to perform without automation.

However, in second place at 22 percent is asset management. Clearly, the need to keep track of assets, as well as the tools needed to repair those assets, is very important to maintenance organizations. Tool management software is a key tool (sorry, we couldn't help ourselves) in any maintenance operation.

To learn more about how asset and inventory management helps companies save money, check out our Three Tips to Optimize Your Spare Parts Inventory Control System.