Find the best MRP Systems

Compare Products

Showing 1 - 20 of 177 products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Sponsored: Sorts listings by software vendors running active bidding campaigns, from the highest to lowest bid. Vendors who have paid for placement have a ‘Visit Website’ button, whereas unpaid vendors have a ‘Learn More’ button.

Avg Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

A to Z: Sorts listings by product name from A to Z.

NetSuite

NetSuite

With an integrated system that includes ERP, financials, commerce, inventory management, HR, PSA, supply chain management, CRM and more – NetSuite enables fast-growing businesses across all industries to work more effectively by a...Read more about NetSuite

Fishbowl

Fishbowl

Fishbowl is the #1 manufacturing and warehouse inventory management software! Its powerful inventory control system gives your small or midsize business the exact tools needed to transform your inventory management and scale your ...Read more about Fishbowl

Global Shop Solutions

Global Shop Solutions

Global Shop Solutions offers ERP software to serve clients across manufacturing industries of all sizes. The multi-modular application is comprised of independent modules for customer relationship management, inventory management,...Read more about Global Shop Solutions

Deskera MRP

Deskera MRP

Deskera enables fast growing businesses to operate more efficiently by providing them with an integrated platform that connects manufacturing, accounting, erp, inventory and warehouse management, order fulfillment, procurement, sa...Read more about Deskera MRP

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Meet Eric, a software expert who has helped 1,534 companies select the right product for their needs.

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Tell us more about your business and an advisor will reach out with a list of software recommendations customized for your specific needs.

STEP 1 OF 4

How many employees are in your company?

QT9 ERP

QT9 ERP

QT9 ERP is a highly-scalable manufacturing platform for connecting and automating business data from multiple systems into one scalable and intuitive solution. QT9 ERP integrates inventory management, accounting management, sales ...Read more about QT9 ERP

REALTRAC

REALTRAC

Realtrac is an on-premise job management solution designed for job shop manufacturers and modular machine shops. It helps small and midsize manufacturers to schedule workflows, manage shop operations, track inventories, manage pur...Read more about REALTRAC

Mar-Kov Chemical Management System

Mar-Kov Chemical Management System

Mar-Kov CMS (Chemical Management System) is a cloud-based process manufacturing solution for process, batch, and formulation based manufacturers. The solution can also be installed on-premise to automate daily routine processes of...Read more about Mar-Kov Chemical Management System

DELMIAworks

DELMIAworks

DELMIAworks (formerly IQMS) ERP is developed specifically for SMB and large discrete and batch process manufacturers in the aerospace, medical device, automotive, food and beverage, consumer products, plastics, packaging, and elec...Read more about DELMIAworks

Rootstock Manufacturing ERP

Rootstock Manufacturing ERP

Rootstock Software is a global provider of manufacturing cloud ERP on the next generation Salesforce Platform. It is purpose-built for mid-size discrete manufacturers who are looking to digitally transform on a future-proof platfo...Read more about Rootstock Manufacturing ERP

R4 Enterprise

R4 Enterprise

Royal 4 Enterprise is an integrated enterprise resource planning (ERP) solution with built-in modules for distribution, manufacturing, planning, inventory management, reporting and company financials. It serves midsize to large en...Read more about R4 Enterprise

ION

ION

ION by First Resonance accelerates manufacturing for companies building mission-critical applications in hardware. ION reliably move parts, workflows, and data through manufacturing while ensuring accurate data capture at each jun...Read more about ION

NutraSoft

NutraSoft

NutraSoft Premium/Ultimate is a food & beverage manufacturing ERP for small to medium sized food & beverage businesses who are looking to manage and grow their operation, increase margins, analyze and improve their production proc...Read more about NutraSoft

Metasystems

Metasystems

ICIM ERP by Metasystems offers small and midsize discrete manufacturers a comprehensive ERP that brings together order management, engineering, manufacturing, CRM, financials and warranty management. It supports the business needs...Read more about Metasystems

Datacor ERP

Datacor ERP

Datacor ERP (formerly Chempax) is an integrated enterprise resource planning (ERP) and customer relationship management (CRM) application designed specifically for chemical process manufacturers and distributors. The solution can ...Read more about Datacor ERP

ShopKeeper Job Control

ShopKeeper Job Control

ShopKeeper Job Control is the flagship of the application suite that makes up the ShopKeeper ERP shop management solution for small- to mid-sized job shops, process shops and contract manufacturers. This solution has been refined ...Read more about ShopKeeper Job Control

ALERE

ALERE

ALERE ERP, brought to you by TIW Technology, is a robust, modular manufacturing package that offers accounting, manufacturing, inventory management, CRM, service, analytics, document management, and data acquisition. Designed for ...Read more about ALERE

Manufacturing & SFC

Manufacturing & SFC

Transform your extensive manufacturing processes into easily accessible, efficient procedures. Geneva Systems offers MRP & Manufacturing Execution software. Our MRP & Manufacturing Execution module is a robust and comprehensive ...Read more about Manufacturing & SFC

Deltek Costpoint

Deltek Costpoint

Deltek Costpoint is an enterprise resource planning (ERP) and management solution designed to meet the requirements of midsize and large enterprise businesses. The solution primarily assists government contractors, professional se...Read more about Deltek Costpoint

MRPeasy

MRPeasy

MRPeasy is a versatile cloud-based ERP system for small and scaling companies (perfect for up to 200 employees). The software offers a complete ERP solution with robust production planning and inventory management functionalities ...Read more about MRPeasy

Cetec ERP

Cetec ERP

Cetec ERP is a manufacturing enterprise resource planning software built for small and medium sized businesses. Cetec ERP's cloud-based software is designed to help these companies efficiently manage all aspects of their manufactu...Read more about Cetec ERP

Popular Comparisons

Buyers Guide

Last Updated: March 16, 2023Manufacturing resource planning software, sometimes called material requirements planning or as MRP II software, is the core technology that sets manufacturing applications apart from other types of business software. This added functionality also adds complexity, both in implementation and in operation. We wrote this buyer’s guide to help buyers navigate the maze of top MRP solutions.

Here’s what we’ll cover:

What Is Manufacturing Resource Planning Software?

Popular MRP Software Comparisons

What Is Manufacturing Resource Planning Software?

“If you fail to plan, then plan to fail” is equally true in sports and manufacturing. Manufacturing MRP software was the first attempt to bring software tools, such as a materials forecast, to formal manufacturing techniques. These systems answer the four basic questions: What do I make? What do I buy? When do I buy? When do I make?

MRP is a subset of enterprise resource planning (ERP). It covers the period of time from when a product is conceived, the raw materials are identified and procured, resources are identified, to when production steps are planned. At that point, manufacturing execution systems (MES) take over.

ERP combines the tools of an MRP system and an MES system, and extends both. Whereas MRP and MES focus on planning for individual jobs, ERP is concerned with a manufacturer's entire chain from buying raw materials to delivery of finished goods to the customer, over the course of time. In other words, MRP software focuses on increasing efficiencies for the course of a job and ERP takes a wider and longer view, over all jobs from end to end.

Basic functions include:

Inventory control and procurement

Production forecasting

Materials costing

Procurement scheduling

Process scheduling applications

Materials costing is usually the core function. It determines what is made versus what is bought. Materials costing works with the inventory system to check quantities on hand and lead times for parts that must be ordered as well as production logs to determine lead times for any sub-assemblies that must be fabricated.

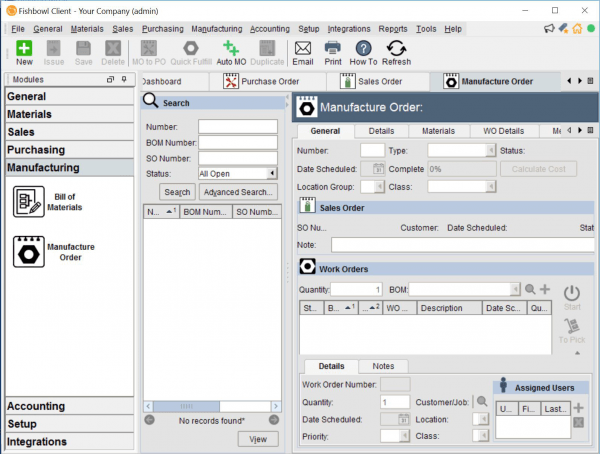

Manufacturing dashboard in Fishbowl

MRP suites may also include a module for configure-price-quote (CPQ) functionality, typically used by sales teams to provide quick and accurate custom quotes for built-to-order operations.

Manufacturing resource planning systems are adaptable to many different philosophies but favor the lean manufacturing and just-in-time (JIT) system. It can support all modes including discrete, process, make to stock (MTS), assemble to stock (ATS), assemble to order (ATO), make to order (MTO) and engineer to order (ETO). However, planning and inventory control functions are generally more important to the “to order” modes due to the time constraints that these modes impose.

MRP ERP systems are generally run on premise. Small shops may have only a single-user system or a small network, while larger organizations may have networks with workstations throughout the facility. Manufacturers have been slower to adopt cloud-based materials requirements planning programs but there is an emerging group of vendors offering a cloud program.

What Type of Buyer Are You?

The first step in evaluating programs, is determining what type of buyer you are. Over 90 percent of buyers fall into one of these three groups:

Full-suite buyer. These buyers value the seamless integration of data and processes that comes from having one system for all functions. For example, they would prefer a full-suite system for estimating, work-in-progress management and accounting that can automatically turn an estimate into a budget for project management and then match invoices to project status and allocate job costs. These buyers favor complete suites like Oracle, SAP, Sage ERP or Microsoft Dynamics.

Departmental buyer. Specialists in one function, such as materials costing, may value the feature depth of best-of-breed solutions designed for their function. These buyers may need specific functionality, like the ability to interface with a specific departmental procurement system.

Small manufacturer. Small organizations often have limited budgets and fewer IT resources available. In many cases, they may be deciding between a new system and a new piece of equipment. These businesses need cost-effective small business MRP solutions that are easy to implement and use. Others may be interested in evaluating free MRP software, which is typically offered in an open source model. Some will prefer full-suite systems, while others may just want one application, such as resource planning or production inventory control.

Benefits and Potential Issues

MRP systems, whether stand-alone or incorporated in an ERP system, offer distinct benefits over less formal production planning systems. These include:

Better planning and resource allocation. One of the greatest strengths of ERP MRP systems is better data and greater insight into the actual costs of inventory, people and equipment, and the actual time costs for each step of the planning and production process.

Greener operations. Better planning and tracking leads to operations that generate less waste and less scrap, reducing environmental impact for those firms. Additionally, as more documentation is kept electronically, it reduces waste paper and cuts paper costs.

Integration with accounting systems. The basic purpose of an MRP ERP system is to decide what to buy and when. Integration with the general inventory makes it easier to track the inventory costs as well as determining lead times. The accounts receivables system handles ordering and payment.

Material requirements planning as a discipline, and the software in general, does have some limitations which can cause problems if not addressed. Planning is based on what should be possible; it ignores current limitations. The inventory and resource planning are based on the assumption that everything is idle. Care must be taken not to over-allocate resources.

Inventory levels are another area of concern. Inventory items tend to two extremes. Either too much is carried in inventory, tying up valuable capital and credit, or too little is carried in inventory, requiring stock to be acquired and delaying production. These systems are supposed to solve this particular problem, but if the model does not adapt to changes in the inventory supply chain, inventory levels on key items will tend to one of the two extremes.

There are also problems that develop over time. The bills of materials, work orders and schedules are based on the assumptions made when the program is first installed. If assumptions are not updated to reflect changes over time as costs fluctuate and productivity changes, the estimates from the MRP will increasingly diverge from the actual costs.

There is also a scope issue. MRP planning is based around particular jobs. While it can increase the efficiency for those jobs, it is possible that over the course of many jobs, the costs will add up. For example, if three jobs are costed that each use four pounds of salt, the system will miss the discount available if 12 pounds of salt are purchased all at once. Among other things, ERP systems expand the scope to solve this issue.

Market Trends to Understand

While you evaluate programs, make sure you consider these market trends:

Advanced planning techniques. As the cost of computing power and storage decreases, more powerful planning models are available which yield better results.

Harmonization. For many years, the goal for MRP and ERP was a single corporate-wide data store. However, that thinking is now evolving to strategically selected systems for specific purposes, sharing information as required.

Use of mobile devices. Until recently, most system designers assumed that the users would be working from a fixed location. Any information had to be entered, remembered or written down and brought to the computer. The new trend is have to mobile systems in the warehouse or shop floor. Operators enter pertinent information directly into mobile systems without having to go to a permanent workstation.

Vendor consolidation. Large vendors like Oracle and Microsoft are buying niche vendors to round out manufacturing application libraries. With so many vendors and products available, this trend will continue for the foreseeable future.

Intelligent inventory tagging. The use of one-dimensional bar coding for equipment and inventory tagging is well established in systems for manufacturers. Recent systems use radio frequency identification (RFID), which can be read remotely to check inventory levels and to confirm equipment availability. Other systems use two-dimensional bar codes which contain descriptive information in addition to an identifier like a part number.

Functional integration with ERP. While there are still numerous stand-alone systems, generally the functions are part of a larger ERP system that is broader in scope than just a facility.

The Vendor Landscape

The scale of solutions varies greatly; different buyer types need to “right size” and compare the vendors that can meet their needs.

This type of buyer... | Should evaluate these systems |

Enterprise resource planning suite buyer | Microsoft Dynamics, Oracle, SAP, Sage |

Departmental buyer | Microsoft Dynamics, Epicor, SYSPRO, Casco |

Small manufacturer | E-Z-MRP, ECi, Exact, Fishbowl |