Best Construction Categories

Best Facilities Management Categories

Best Human Resources Categories

Best Legal Management Categories

Best Manufacturing Categories

Best Medical Categories

Best Property Management Categories

Get 1-on-1 advice in 15 minutes. It's free.

Josh P.

3 Tips To Optimize Your Spare Parts Inventory Management

Spare parts inventory control management is critical to avoiding both stockouts and excess inventory because it gives you a system for identifying what you need, what you have, and how and when to replenish inventory. Our 2024 Supply Chain Plans Survey finds that when asked about their top three supply chain challenges for 2024, 19% of surveyed U.S. executives say a lack of inventory, and 10% say excess inventory.* However, both can present huge problems for operations and inventory management.

Below, we break down the importance of developing a spare parts inventory system, three tips for optimizing your solution, and software that can make it easier to manage your inventory. We also draw on the experience of David Berger, an asset management consultant of 25 years, a CMMS expert, and a regular contributor to Plant Services magazine and other industry publications. [1]

Why is it important to optimize your spare parts inventory management?

For SMB leaders, optimizing your spare parts inventory management is important because you can save money instead of purchasing excess inventory you may not need. Your savings come from both the cost of inventory and expenses associated with storing and maintaining it.

You also benefit your production processes, whether they involve building components in a factory or preparing food for hungry guests. With an optimized spare parts management system, you ensure you have what your team needs to produce the goods your customers expect.

By spending time fine-tuning your system for spare parts management, you can prevent budget and inventory shortage issues, which will give you more time to focus on growing your business.

3 tips to optimize your spare parts inventory management

Before you use any of the tips below, it helps to get the right stakeholders on board. Otherwise, your optimization efforts may not impact enough of your company's processes to be effective. For instance, by collaborating with maintenance, engineering, and finance teams, you can balance financial and operational goals. [2] At the same time, you can reduce the risk of downtime resulting from inventory shortages.

Ultimately, your goal is to achieve these three elements [3]:

Optimized performance.

Prioritized rebalancing, which governs which inventory to shift to other locations based on demand and production levels.

Stock control and predictability.

Here are some more specific, complementary strategies you can use to optimize your spare parts inventory solution.

Tip #1: Use ABC and XYZ analyses to identify critical components

For example, if you are a maintenance manager, you probably know which machines are critical to your operations and are the most important to closely track. Your first step is to identify the parts you'll need to have on hand to keep your most business-critical assets running.

After making a list of these important spare parts, you can break them into priority categories using the ABC and XYZ analysis methods.

How to perform ABC analysis

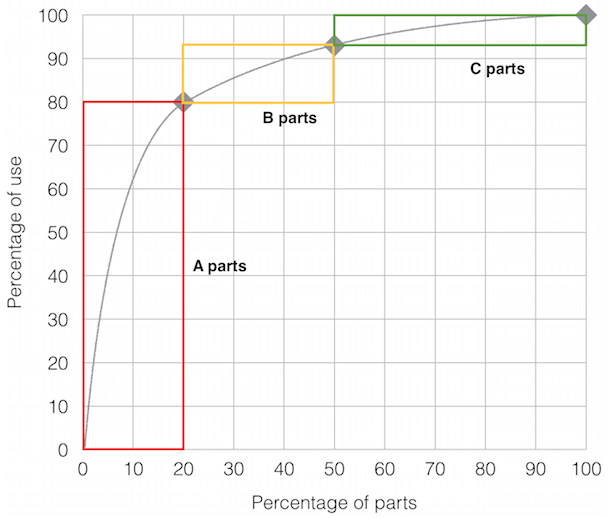

ABC analysis involves focusing on the percentage of use for each part in your inventory.

A parts make up about 80% of all parts used but account for 20% or less of inventory stock.

B parts make up about 25% of usage but account for about 30% of inventory stock.

C parts make up about 5% of usage but account for about half of the inventory stock.

When displayed visually, the breakdown looks like the graph below, where the x-axis represents the percentage of parts, and the y-axis represents the percentage of use:

As you can see from the graph above, the A parts represent 80% of the parts being used for repairs. At the same time, they only make up 20% of the parts on hand. Given that this relatively small percentage of the spare parts inventory is consumed the most frequently, it will also need to be replenished most often.

How to perform XYZ analysis

XYZ analysis is a variation that focuses on costs. For example, parts labeled X would make up 20% of the spare parts inventory but account for 80% of the inventory's value.

You can choose just one of these two methods of analysis or use them both.

XYZ analysis has a similar percentage breakdown as the ABC method:

X parts make up about 80% of inventory value but account for 20% or less of the amount of inventory you have in stock.

Y parts make up about 25% of inventory value but account for about 30% of your inventory stock.

Z parts make up about 5% of inventory value but account for about half of inventory stock.

The goal is to get a clear breakdown of the most frequently used parts and then create a cost-effective plan for replenishing them. The objective is to avoid a "stockout," which is when a necessary spare part is unavailable. David Berger tells us that to avoid stockouts, you must have plenty of inventory—but too much inventory can be prohibitively expensive to store.

"If I get too many items in stock, it's going to cost a fortune," he explains. "But if it's a high-volume [part] and I don't have enough, that stockout might cost me a fortune in terms of the availability of my asset."

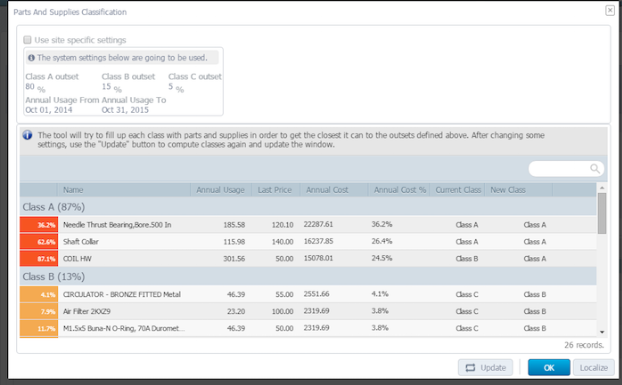

Use a CMMS to analyze your spare parts

A CMMS can perform ABC and XYZ calculations for you. For example, in the screenshot below, users define annual usage percentages for A, B, and C classes of parts. The system then automatically organizes spare parts into each class based on usage.

ABC analysis tools in Fiix (Source)

After this analysis, you will have all your inventory items categorized into high-, medium-, and low-volume classes and/or high-, medium-, and low-cost classes. At this point, you can start designing plans to optimize inventory for the most used parts.

Tip #2: Use sawtooth diagrams to manage replenishment

With the critical "inventory A" parts identified, it's time to establish some parameters for keeping your inventory volumes balanced.

For each part, Berger says, establish the maximum level of stock you can accommodate as well as a reorder point, which refers to the point where you need to order more parts to prevent a stockout.

In the diagram below, we see what is called a "sawtooth curve." This displays how inventory stock gets depleted and replenished over time:

![Inventory stock represented by a sawtooth curve [4]](https://images.ctfassets.net/o5y0ehllhbif/4j3v23RTaInqlFfdYL1Vee/902e06ca1c9b73ec5be96fda4d631cee/Saw_tooth_model_image.png)

Inventory stock represented by a sawtooth curve [4]

As time passes, the stock gets depleted, drawing closer to zero, representing a stockout.

By leveraging the amount of time it takes to get a new shipment of parts (the "lead time"), you can determine the most appropriate reorder point. The amount of time between shipments is known as the "cycle time."

Establish a minimum and maximum inventory level for each part. The minimum inventory level is the smallest number of a given part you can have on hand at any one time without negatively impacting production. The maximum represents the largest number of that part you can accommodate given your storage and maintenance limitations.

If it's a critical part, Berger adds, make sure to give yourself a higher minimum level so your stock lasts through the lead time.

"I would set my reorder point higher than the minimum because once I reorder, I need to allow for the lead time because I'm still depleting the stock," he says. "It could be just one in stock, and I'm hoping I don't have another occurrence, but that might be too risky for critical parts."

How to calculate the optimal order quantity

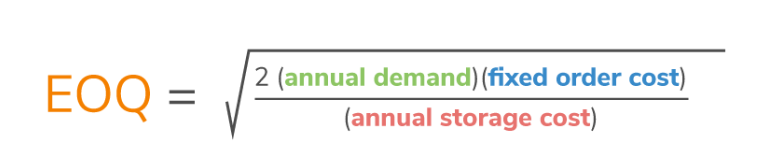

A separate calculation, the economic order quantity (EOQ), is also helpful here. The EOQ refers to the number of spare parts to order based on your annual demand, the cost to store the part, and the fixed cost to reorder parts.

EOQ is represented as:

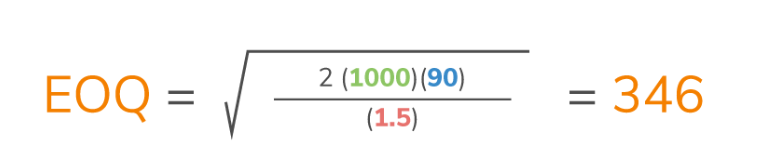

For example, let's say that for a given part, you have an annual demand of 1,000 units—the cost to store the part for a year is $1.50, and it costs about $90 to place and receive an order. Plugging those numbers in gives us:

Therefore, the most economical reorder amount would be 346 units.

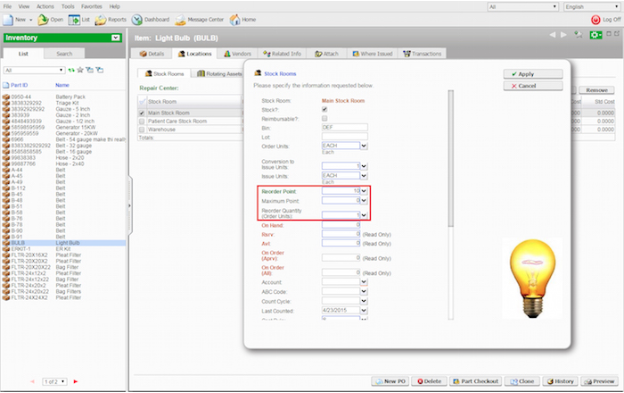

Use a CMMS to optimize inventory

Many systems can assist in this process by automatically calculating the average lead time, best reorder point, and the average usage for a given item, Berger says.

Inventory management functionality in Maintenance Connection (Source)

As workers complete tasks that consume that part and then enter that usage into the system, a CMMS can automatically reorder the part when the specified point is reached. In the red box, we see fields for the reorder point, maximum point, and reorder quantity.

These processes can be tedious and prone to human error when performed manually. But a CMMS with inventory management features can help you decrease inventory levels over time—and save money—by automating the calculations needed to decide on optimal reorder points and quantities.

In some situations, a part could be expensive, rarely used, and comes with a long lead time. In this case, Berger says, maintenance professionals should investigate various options to ensure the part is available when needed—without letting it eat into their budget.

Some options to reduce the risk of stockouts include:

Allowing a local vendor to store the item for less money.

Seeking out vendors with shorter lead times.

Keeping only one part on hand to reduce costs but using a second, redundant part to keep operations going when the first one fails.

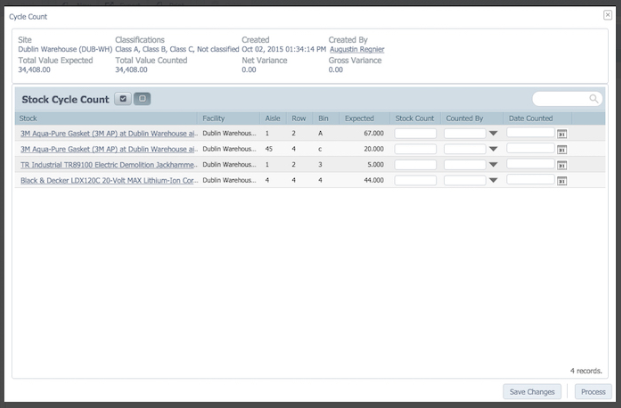

Tip #3: Perform cycle counts and train employees

The final elements of inventory management involve processes that ensure accuracy. With the ABC analysis complete, maintenance professionals can perform cycle counts (basic audits of a specific section of the inventory, such as class-A parts) on specific days. The purpose of cycle counts is to verify inventory accuracy using a physical count. It's also useful for correcting any discrepancies between what's in the system and what you have available.

Performing cycle counts each month or quarter is more efficient than doing a comprehensive inventory count at the end of each year. In this way, according to Berger, you can reduce the disruption that comes with stopping operations.

Depending on the size of your inventory and how many employees you have, cycle counts should be performed on the top 10% of inventory items, which are those that are most valuable or critical.

Use a CMMS to streamline inventory counts

By using a cloud-based CMMS with mobile capabilities, workers can enter the counts directly into the system with a smartphone or tablet. They can also include their name and the date they took the count. Software makes this process easier and more accurate—and also leads to greater accountability among the team.

Cycle count functionality in Fiix (Source)

Cycle counts and other procedures for entering data into a CMMS require commitment from employees and a training system. If workers don't know how to enter data correctly or they are hesitant to use the software, inventory and other data related to maintenance won't be up to date. Without clearly defined procedures, several problems will arise.

As Berger points out, "When someone is looking for a part and it's not there, they can lose faith in the system."

Follow these three steps to ensure data accuracy:

Define standard processes for receiving, storing, issuing, and returning spare parts: An employee may forget to record when they've taken a part from storage or when they return one. You should also establish a set amount of time workers have to record changes in the system so that the data is as up to date as possible.

Train every person involved with using spare parts: From technicians to managers, Berger says every person who could affect inventory management should be trained to follow these standards. Fortunately, many software vendors offer training courses and online resources, such as knowledge bases and FAQs, to help users understand how the system works and how to get the most out of it.

Hold employees accountable for proper execution: Berger says employees should be held accountable for bad inventory management habits, similar to how you'd hold them accountable for failing to complete a maintenance task. Make it clear to each worker that proper inventory management is an essential element of their job by providing examples of how crucial it is to prevent downtime.

How to leverage inventory software

To get the most out of your inventory management software, you should:

Identify the processes you use to manage your spare parts, including how you receive them, record the number you have, store them, issue them to different departments, and return them.

Assess your potential software options to figure out which solutions can perform all of the above functions.

Pinpoint the measurement strategies you’d like to use, such as XYZ, ABC, or sawtooth analysis, and determine whether the software you are considering uses these or comparable methods.

Set aside time to train employees on how to use the solution you choose.

Hold employees responsible for using the software, and provide extra coaching if they start returning to previous practices.

You have a range of software options when it comes to streamlining and automating elements of your inventory management system. You can also use Software Advice's directories to start comparing your choices:

Build a winning spare parts inventory management system

You now understand both the value of a spare parts inventory management system and how to build one. By performing ABC and XYZ analyses, starting with the top 10% of your parts, and scheduling cycle counts, you can create a proactive solution that will avoid both shortfalls and excesses.

Looking forward, you should dig deeper into your inventory management software options, how to succeed in your new software implementation, and the value of inventory accounting. Use the following resources to get going:

Sources

David Berger, LinkedIn

Improve Asset Performance by Segmenting MRO Spare Parts Inventory, Gartner

Drive to Inventory Excellence by Operating 3 Performance Gears, Gartner

Image source, The Planning Master

Survey methodology

*Software Advice's 2024 Supply Chain Plans Survey was conducted online in February 2024 among 1,100 respondents in the U.S. (n: 300), U.K. (n: 200), France (n: 200), Germany (n: 200), and Australia (n: 200). The goal of the study was to learn about the challenges and plans of supply chains. Respondents were screened for employment as supply chain or logistics professionals at a small to midsize business (<USD $500M in annual revenue, employing <1,000 people).