Best OEE Software of 2026

Updated January 27, 2025 at 9:58 AM

- Popular Comparisons

- FrontRunners

- Buyers Guide

Compare Products

Showing 1 - 25 of 113 products

Compare Products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Average Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

Alphabetically (A-Z): Sorts listings by product name from A to Z.

DELMIAworks (formerly IQMS) ERP is developed specifically for SMB and large discrete and batch process manufacturers in the aero...Read more about DELMIAworks

SafetyChain's digital plant management platform gives process manufacturers the flexibility to rapidly address urgent challenges...Read more about SafetyChain

SafetyChain's Best Rated Features

See All

SafetyChain's Worst Rated Features

See All

Guidewheel's manufacturing operations cloud is a plug-and-play system designed to simply and cost-effectively give any manufactu...Read more about Guidewheel

MaintainX is a maintenance and asset management platform built for industrial and frontline teams. It helps organizations stream...Read more about MaintainX

MaintainX's Best Rated Features

See All

MaintainX's Worst Rated Features

See All

Evocon is an OEE (overall equipment effectiveness) solution designed to help businesses within the manufacturing industry to mon...Read more about Evocon

Evocon's Best Rated Features

See All

Evocon's Worst Rated Features

See All

Limble is a CMMS platform designed to optimize maintenance operations and improve compliance. Its work order management allows u...Read more about Limble

Limble's Best Rated Features

See All

Limble's Worst Rated Features

See All

WorkClout is a quality management platform for automotive parts manufacturers. Our software helps streamline & automate internal...Read more about WorkClout

XL Productivity Appliance is a cloud-based and on-premise overall equipment effectiveness (OEE) software that helps manufacturin...Read more about Vorne XL Platform

Vorne XL Platform's Best Rated Features

See All

Vorne XL Platform's Worst Rated Features

See All

Fusion Operations is a manufacturing execution system that provides real-time data for production management. It helps manufactu...Read more about Fusion Operations

Fusion Operations's Best Rated Features

See All

Fusion Operations's Worst Rated Features

See All

ProShop is a machine shop and manufacturing process management solution designed for small and midsize manufacturers. It offers ...Read more about ProShop ERP

ProShop ERP's Best Rated Features

See All

ProShop ERP's Worst Rated Features

See All

SmartMon is a platform that combines features of a MES (Manufacturing Execution System) and OEE (Overall Equipment Effectiveness...Read more about SmartMon

SmartMon 's Best Rated Features

See All

SmartMon 's Worst Rated Features

See All

PerformOEE Smart Factory Software is an overall equipment efficiency (OEE) solution for manufacturing businesses that offers too...Read more about PerformOEE Smart Factory Software

Open Automation Software is an industrial Internet of Things (IoT) suite designed to help businesses connect data sources to the...Read more about Open Automation Software

Opstech is a customizable MES platform used by production managers to achieve efficient and quality-focused production lines. Wi...Read more about Opstech

InfinityQS® ProFicient modernizes SPC-based quality management for total manufacturing optimization—from the plant floor to the ...Read more about ProFicient

WinSPC is a statistical process control solution aimed at helping businesses of varying sizes manage and improve quality across ...Read more about WinSPC

Worximity helps food processing manufacturers and companies with their performance and data visualization.. From the shop floor...Read more about Worximity

Automation Intellect's IIoT platform empowers manufacturing teams to utilize real-time, actionable data to extract exceptional v...Read more about Automation Intellect

WeASSIST is a cloud-based solution for monitoring and optimizing manufacturing processes across industries. The system is design...Read more about WeASSIST

Infor MES, previously known as Shopfloor-Online, is a versatile manufacturing execution system available on-premise and in the c...Read more about Infor MES

FSWorks is a workstation-level data collection software that provides data entry and a library of analytic tools. It helps users...Read more about FSWorks

FSWorks's Best Rated Features

See All

FSWorks's Worst Rated Features

See All

SQUEAKS is a Smart Factory digital communication and collaboration platform that helps teams better understand "what's important...Read more about SQUEAKS

Amper is a cloud-based IoT management platform. It caters to businesses looking to deploy and manage Internet of Things devices ...Read more about Amper

WATS is a test data management solution that allows businesses in the electronics industry to collect and analyze test data for ...Read more about WATS

While over 90% of manufacturers have a digital transformation strategy, most are stuck on what to do, where to go, and very few ...Read more about Shoplogix Smart Factory Platform

Popular Comparisons

Your Guide to Top OEE Software, September 2022

Software Advice uses reviews from real software users to highlight the top-rated OEE products in North America.

Learn how products are chosenExplore FrontRunners

“Usability” includes user ratings for Functionality and Ease of Use.

“Customer Satisfaction” includes user ratings for Customer Support, Likelihood to Recommend and Value for Money.

Reviews analysis period: The reviews analysis period spans two years and ends the 15th of the month prior to publication.

Buyers Guide

This detailed guide will help you find and buy the right oee software for you and your business.

Last Updated on January 27, 2025Overall equipment effectiveness (OEE) is an important and commonly tracked key performance indicator (KPI) that conveys how effectively assets are used in a manufacturing setting. It serves as a benchmark that shows you exactly how production is going and where to improve.

OEE is such an important part of continuous improvement and lean manufacturing that software exists specifically to help companies track and optimize it. By using this software, companies can make significant improvements to boost production and reduce costs.

Hands down, OEE software is the best tool available to utilize production data and see a real manufacturing impact. This guide is designed to help software seekers learn more about how the system works, its benefits and purchasing details to make the best choice.

In this guide, we'll cover:

Common Features of OEE Software

Pricing and Purchasing Options

What Is OEE Software?

OEE software helps gather and analyze the production data you create every day in order to see where you're wasting time and money. These systems transform this dark data into visuals that reveal trends or immediate problems. For example, waterfall and bar charts can help you see which manufacturing process contributes to downtime. It lets you take a deep dive to see the OEE of a certain product, shift or facility at a glance.

OEE is typically calculated as (Availability x Performance x Quality). Each of these components is quantifiable, and the OEE software uses this information to present the data in dashboards. These data visualizations give you a view of the trends and potential problems throughout the manufacturing process.

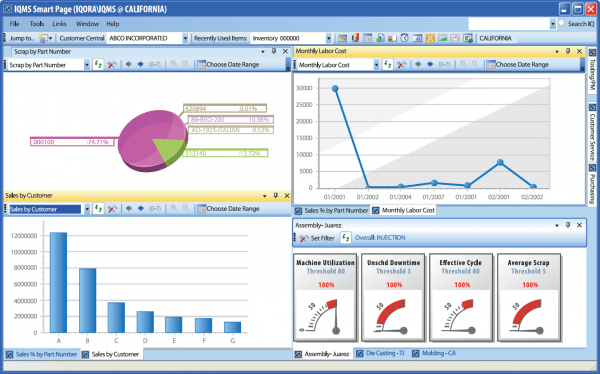

An example of a dashboard as seen in IQMS ERP

In addition to real-time dashboards, OEE systems include strong reporting functionality to generate reports on any production process. This way, you can easily share performance reports with the appropriate departments.

Common Features of OEE Software

Data collection | Enables the transfer of performance data from assets on the production line by integrating with controllers on machines, then manipulating the data into various formats. |

Alerts and notifications | The system allows users to set up custom alerts so the appropriate worker is notified if performance readings from machines exceeds a certain threshold, indicating a problem that needs attention. |

Dashboard | Users can customize a KPI dashboard to include their most critical metrics to see OEE at a glance on a desktop computer or through any web-enabled device. |

Reporting | Generate reports using the data gathered from production machines on specific products, assets or locations. |

Analytics | Some vendors offer stronger data-leveraging functionality beyond static reports—Analytics goes another step to pull insights from the data to improve manufacturing performance. |

What Type of Buyer Are You?

Whether you're just getting started with software or ready to optimize parts of your manufacturing business, several types of systems exist to assist you in your goals:

You're new to manufacturing software. Perhaps you're a small manufacturer using manual methods (like spreadsheets) to track production and quality. To begin automating your daily tasks, look for an enterprise resource planning (ERP) system. This holistic software can assist your entire operation from tracking materials and inventory to supply chain management and sales.

You need to improve overall quality. A couple of types of manufacturing software are designed to gather data about production quality and drive improvements. A manufacturing execution system (MES) is focused on optimizing all the specific processes that go into producing a finished item. An OEE system contributes to quality as well by providing benchmarks to achieve.

You want to improve a specific process. This could include capacity planning, inventory or PLM. Some systems are built to improve specific parts of the production process.

Capacity planning software factors in all the labor hours, raw materials, equipment and other resources to determine how to plan production in the most efficient way possible.

Inventory management software tracks all the materials and parts needed to produce an item, helps to reduce carrying costs and optimizes stock-on-hand.

Product lifecycle management (PLM) software is focused on product quality, using design, engineering and data analytics tools to maximize the value of a product from creation to sale to disposal.

Benefits and Potential Issues

OEE software leads to a few key manufacturing benefits:

Real-time production visibility. Without the right technology, there is no effective way to keep an eye on production metrics in real-time. OEE software gives manufacturers a valuable view into their operations to reveal opportunities for improvement.

True data-driven decisions. Now with a visual dashboard of the most important KPIs for a certain type of manufacturing, companies can make more confident business decisions based on actual data, instead of what they thought was happening on the production line.

Encourages ongoing improvements. Visualizing production data ensures that the performance of the manufacturing process is a consistent source for decision-making—The data offer clear ways to improve production.

Market Trends to Understand

Some events occurring in the world of manufacturing may impact your software selection decision:

Outsourcing is beneficial if done strategically. Even as thousands manufacturing jobs are coming back to the United States from countries like China and Germany, strategic outsourcing is becoming a popular business move. The growth and diverse nature of external manufacturing companies offer opportunities for beneficial partnerships. These outside companies can produce different parts of the same end product for significant cost savings and a boost to efficiency.

Affordable technology enables condition monitoring for small manufacturing. When technologies become cheaper, more small businesses are able to use sensors or other devices to gather and use data from the production line. This technology is also beneficial for maintenance management of important assets, extending their useful life by catching problems early.

3D printing can reduce costs, boost complexity of designs. Additive manufacturing, better known as 3D printing in a manufacturing setting, is becoming a more common practice by companies of all types and sizes. 3D printing allows manufacturers to create more complex parts in a single print, which can reduce the burden on other production machines and increase efficiency.

Pricing and Purchasing Options

Most OEE software vendors don't offer specific pricing publicly, but those who do typically offer a cloud-based system with subscription pricing per month or year. Additional costs may be required to integrate additional assets.

Maybe you prefer to keep your data close by—Most vendors also offer on-premise OEE systems, installed on your computers. Compared to cloud-based software, on-premise systems usually include a higher one-time payment for perpetual use. With on-premise software, your company may also need to invest in IT staff who can secure and maintain the servers and software.