Best Bill of Materials software of 2026: which is right for you?

- Popular Comparisons

- Buyers Guide

Compare Products

Showing 1 - 25 of 157 products

Compare Products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Average Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

Alphabetically (A-Z): Sorts listings by product name from A to Z.

NetSuite is an AI-powered cloud-based business management suite that incorporates ERP, financial management, CRM and eCommerce f...Read more about NetSuite

NetSuite's Best Rated Features

See All

NetSuite's Worst Rated Features

See All

Striven is a cloud-based enterprise resource planning (ERP) solution suitable for many industries and organizations of all sizes...Read more about Striven

Striven's Best Rated Features

See All

Striven's Worst Rated Features

See All

JobBOSS² is a job shop management software designed for custom manufacturers and machine shops. It supports make-to-order manufa...Read more about JobBOSS²

JobBOSS²'s Best Rated Features

See All

JobBOSS²'s Worst Rated Features

See All

Global Shop Solutions provides a comprehensive suite of enterprise resource planning (ERP) tools and solutions designed to help ...Read more about Global Shop Solutions

Cetec ERP is a manufacturing enterprise resource planning software built for small and medium sized businesses. Cetec ERP's clou...Read more about Cetec ERP

Cetec ERP's Best Rated Features

See All

Cetec ERP's Worst Rated Features

See All

M1 ERP is a subscription-based enterprise resource planning (ERP) system, available on-premise or via the cloud, that automates ...Read more about M1 ERP

M1 ERP's Best Rated Features

See All

M1 ERP's Worst Rated Features

See All

DELMIAworks (formerly IQMS) ERP is developed specifically for SMB and large discrete and batch process manufacturers in the aero...Read more about DELMIAWorks

Sage X3 is a powerful ERP software solution designed for midsized national and global manufacturers, distributors, and after-sal...Read more about Sage X3

Sage X3's Best Rated Features

See All

Sage X3's Worst Rated Features

See All

aACE is a powerful, comprehensive business management solution designed for companies that have outgrown small-business packages...Read more about aACE

BatchMaster Software offers process manufacturing software solutions for the food, chemical, nutraceutical and pharmaceutical in...Read more about BatchMaster ERP

BatchMaster ERP's Best Rated Features

See All

BatchMaster ERP's Worst Rated Features

See All

Deacom, an ECI Software Solution, is a comprehensive ERP (Enterprise Resource Planning) platform with a rich set of capabilities...Read more about Deacom ERP

Epicor Kinetic is a global, cloud-focused cognitive ERP solution built for manufacturers, driving profitability through real-tim...Read more about Kinetic

Kinetic's Best Rated Features

See All

Kinetic's Worst Rated Features

See All

SyteLine is an enterprise resource planning software created specifically for engineer-to-order, make-to-order, make-to-stock, a...Read more about SyteLine

SyteLine's Best Rated Features

See All

SyteLine's Worst Rated Features

See All

Royal 4 Enterprise is an integrated enterprise resource planning (ERP) solution with built-in modules for distribution, manufact...Read more about R4 Enterprise

Fishbowl’s powerful inventory management software is designed to help businesses streamline operations, improve accuracy, and sc...Read more about Fishbowl

Fishbowl's Best Rated Features

See All

Fishbowl's Worst Rated Features

See All

MRPeasy is a versatile cloud-based ERP system for small and scaling companies (perfect for up to 200 employees). The software of...Read more about MRPeasy

MRPeasy's Best Rated Features

See All

MRPeasy's Worst Rated Features

See All

Realtrac is an on-premise job management solution designed for job shop manufacturers and modular machine shops. It helps small ...Read more about REALTRAC

REALTRAC's Best Rated Features

See All

REALTRAC's Worst Rated Features

See All

Deltek Costpoint is an enterprise resource planning (ERP) and management solution designed to meet the requirements of midsize a...Read more about Deltek Costpoint

Deltek Costpoint's Best Rated Features

See All

Deltek Costpoint's Worst Rated Features

See All

ALERE ERP, brought to you by TIW Technology, is a robust, modular manufacturing package that offers accounting, manufacturing, i...Read more about ALERE

Epicor Advanced MES is a manufacturing execution system that is suited to plastic molders, repetitive manufacturers and those wi...Read more about Epicor Advanced MES

No reviews yet

recommendations

ERP software designed for ETO manufacturers. Total ETO streamlines sales, engineering, procurement, manufacturing, and accountin...Read more about Total ETO

Total ETO's Best Rated Features

See All

Total ETO's Worst Rated Features

See All

AccountMate is a hybrid accounting solution that caters to small and midsize businesses and offers them tools and functionalitie...Read more about AccountMate

QT9 ERP is a highly-scalable manufacturing platform for connecting and automating business data from multiple systems into one s...Read more about QT9 ERP

Acumatica Cloud ERP is a comprehensive business management system. It caters to a variety of industries, such as finance, manufa...Read more about Acumatica Cloud ERP

Acumatica Cloud ERP's Best Rated Features

See All

Acumatica Cloud ERP's Worst Rated Features

See All

SAP S/4HANA Cloud is a cloud-based and on-premise enterprise resource planning (ERP) solution. It is suitable for small, midsize...Read more about SAP S/4HANA Cloud

SAP S/4HANA Cloud's Best Rated Features

See All

SAP S/4HANA Cloud's Worst Rated Features

See All

Popular Comparisons

Buyers Guide

This detailed guide will help you find and buy the right bill of materials (bom) software for you and your business.

Last Updated on January 27, 2025Accuracy of production and consistency characterize strong manufacturing operations. Like a good recipe, each item on a bill of materials needs to be exactly right to produce high-quality end products while maintaining equipment effectiveness and production rates.

Bill of materials (BOM) management is a critical functionality for modern manufacturing operations, and is often included as part of a manufacturing resource planning (MRP) system or enterprise resource planning (ERP) system.

With hundreds of options for manufacturing systems, it can be challenging to identify the capabilities you need and find the vendors that best meet your requirements. This Buyer's Guide is designed to give you the information you need to make the best decision for your business quickly.

Here's what we'll cover:

What Is Bill of Materials Software?

Common Features of Bill of Materials Software

Benefits of Bill of Materials Software

Popular Bill of Materials (BOM) Softwaer

What Is Bill of Materials Software?

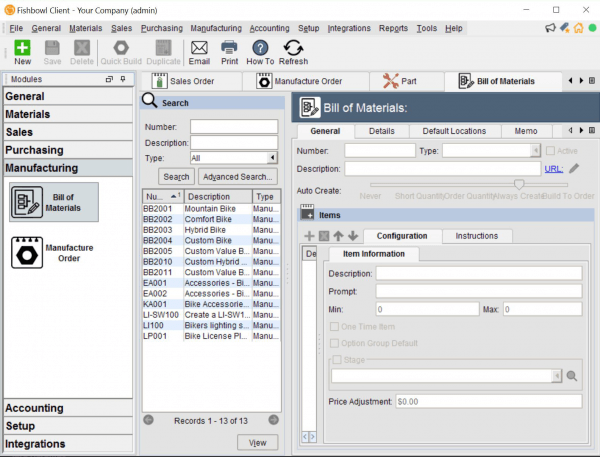

Bill of materials (BOM) software automates the process of listing the individual components that make up a product in the manufacturing setting. Users can create item profiles for every part that goes into a specific product, then use these to create multiple lists for a single product to show subassemblies.

For years, this process was performed manually on paper. Spreadsheets helped businesses track more information about each part than was possible on paper, but the manual entry of data is tedious and error-prone.

Many still rely on Excel, but manufacturing systems and ERPs with BOM functionality help companies manage and automate this important task. This becomes crucial when working with multiple teams, sites and service providers on the same project.

The BOM view in Fishbowl Manufacturing, with fields to create a new item profile

BOM software is also necessary for growth. Optimizing accuracy and quality from the beginning of the process allows manufacturers to increase production volume and scale the business.

Common Features of Bill of Materials Software

The features included in a BOM system support data entry, workflow management and data analysis functions. These may include:

Multilevel BOM | Create profiles for items in the system that can then be combined to create a completed project. BOM software ensures that all subassemblies and component parts are listed in the system for accuracy. |

Routing management | Determine the best machines and equipment to use for a specific project. Takes into account the characteristics of each production asset to automatically distribute the work in the most efficient way possible. |

Cost maintenance | Calculate costs for each item in a bill of materials. This tool can multiply the cost by quantities needed and factor in any other costs, such as tooling or overhead operational costs. |

Change history | Track fluctuations in the availability and cost of materials and parts. By tracking all of these changes, software helps companies remain in compliance and maintain a paper trail for potential audits. |

Document management | Keep important documents accessible to every organization involved in the supply chain. |

Reporting | Generate reports to see how each item is utilized, which can be useful for identifying problems and streamlining production processes. Reports can also be exported to external systems, such as an ERP. |

Benefits of Bill of Materials Software

Spreadsheets have been a popular tracking method for many years, but thousands of companies reached out to Software Advice in the past year alone to upgrade to dedicated manufacturing systems.

Any organization with plans to scale the business and take on a larger volume of orders needs true automation to manage the increased complexity of a modern manufacturing operation.

Here are the main benefits BOM offers over spreadsheets:

Easy-to-find items. BOM software assigns a code to each item and lets users create custom names, making it simple and quick to find specific items or subassemblies in the system.

Share real-time data. When implemented, BOM software and other manufacturing systems are accessible by other stakeholders, including management, external service providers and other logistics teams in real time. This means any changes that occur at one site will be reflected immediately in the system for everyone else, preventing any production mistakes as a result of miscommunication.

Maintain production history. Audits and compliance problems can cause big headaches for manufacturers. With a BOM system, every change to items or the production process is recorded and saved, so documents proving compliance are always on-hand.

Popular Bill of Materials (BOM) Software Comparisons

Fishbowl Manufacturing vs NetSuite

E2 Shop System vs NetSuite

Odoo vs E2 Shop System

Priority vs Prodsmart

Market Trends to Know About

Mobile devices are changing manufacturing. Mobile devices are increasingly being implemented as work tools in various industries, including manufacturing. With these devices, workers can carry all the important production information wherever they are in your shop, and maintenance teams in your plant can receive repair requests immediately.

ERP integration becomes more widespread. ERP systems offer a holistic view of operations, so many companies, including manufacturers, are adopting these platforms to manage the front and back end of the business. An MRP offers similar functionality with a focus on manufacturing, while most other manufacturing systems, such as a manufacturing execution system (MES), can integrate with an organization's existing ERP.

3D printing is extending asset lifespan. 3D printing is another trend seeping into the manufacturing world. Also known as "additive manufacturing," companies are using 3D printing technology to craft spare parts to maintain important machinery, saving money and time. It's also being used as a supplement to the typical production process.

Contract manufacturing and outsourcing on the rise. More and more manufacturers are opting to outsource portions of their production process to save money and improve quality by working with external providers that can perform certain processes better. Modern manufacturing software is able to integrate each of these partners into one system.