Best Metal Fabrication Software of 2026

Updated January 14, 2026 at 5:58 AM

Written by Olivia Montgomery, PMP

Associate Principal Analyst

Edited by Parul Sharma

Editor

Reviewed by Bryan Dengler

Senior Advisor

Talk with us for a free 15-min consultation

Expert advisors like Jacqueline, who have helped 1,000+ companies, can find the right software for your needs.

- All Software

- Software Advice FrontRunners

- Popular Comparisons

- Buyer's Guide

- Frequently Asked Questions

Metal fabrication software helps manufacturers design, plan, and manage metal fabrication processes, improving precision, reducing waste, and boosting productivity. Metal fabrication software is a specialized material requirements planning (MRP) system and the leading manufacturing segment for software inquiries we get. With over 100 tools covering varied operational models, integration needs, or regulatory contexts, choosing the right system can be daunting. To help you narrow it down, I worked with our metal fabrication software advisors to curate a list of recommended productsi and a list of the metal fabrication software FrontRunners based on user reviews. For further information, read my metal fabrication software buyer's guide.

Metal Fabrication Software

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Average Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

Alphabetically (A-Z): Sorts listings by product name from A to Z.

NetSuite is an AI-powered cloud-based business management suite that incorporates ERP, financial management, CRM and eCommerce f...Read more about NetSuite

NetSuite's Best Rated Features

See All

NetSuite's Worst Rated Features

See All

The Job Shop Management Solution for Manufacturers. JobBOSS² helps job shops, machine shops, make-to-order manufacturers, and c...Read more about JobBOSS²

JobBOSS²'s Best Rated Features

See All

JobBOSS²'s Worst Rated Features

See All

Global Shop Solutions provides a comprehensive suite of enterprise resource planning (ERP) tools and solutions designed to help ...Read more about Global Shop Solutions

Cetec ERP is a manufacturing enterprise resource planning software built for small and medium sized businesses. Cetec ERP's clou...Read more about Cetec ERP

Cetec ERP's Best Rated Features

See All

Cetec ERP's Worst Rated Features

See All

Striven is a cloud-based enterprise resource planning (ERP) solution suitable for many industries and organizations of all sizes...Read more about Striven

Striven's Best Rated Features

See All

Striven's Worst Rated Features

See All

Software Advice FrontRunners 2026

(1768)

(1282)

(157)

(105)

(198)

(164)

(344)

(243)

(865)

(367)

Best for Customization

NetSuite

- Screenshots

Highly Rated for Quick Adoption/Easy Adoption

Odoo

- Screenshots

Most Used By Construction

Sage X3

- Screenshots

Best for Quick Implementation

- Screenshots

Best for Customer Satisfaction

Genius ERP

- Screenshots

Most Used By Electrical/Electronic Manufacturing

ERPAG

- Screenshots

Most Rated for SMBs

- Screenshots

Most Used By Mechanical/Industrial Engineering

JobBOSS²

- Screenshots

Most Used By Construction

Sage 100

- Screenshots

Methodology

The research for the best metal fabrication software list was conducted in October 2025. We evaluated data (user reviews and demand signals) from the past 24 months as of the research date. Read the complete methodology.

Popular Metal Fabrication Comparisons

Buyer's Guide

This detailed guide will help you find and buy the right metal fabrication software for you and your business.

Last Updated on January 27, 2025Here's what we'll cover:

Metal fabrication software essentials

What is metal fabrication software?

Features of metal fabrication software

How to choose the best metal fabrication software

Understanding metal fabrication market trends

Metal fabrication software essentials

Metal fabrication software is a specialized tool designed to assist in the design, planning, and management of metal fabrication processes. It helps manufacturers by improving precision, reducing waste, and enhancing productivity through features like purchase order management, production scheduling, and real-time monitoring. Metal fabrication is the leading manufacturing segment that software buyers have inquired about, with our software advisors helping over 500 buyers in the past year. [1]

“Metal fabrication software is the ideal, industry-specific MRP system to help you plan materials, manage inventory, and streamline procurement specifically for metal projects. It also teams up with MES systems to give you real-time insights and control over shop floor activities, making your production process smoother and more efficient,“ explains top advisor, Bryan Dengler.

To give you an idea of the market, our site features 126 different metal fabrication products, and in the past year alone, we've published over 940 reviews for 42 of these products. The majority of user reviews come from small to midsize businesses, with 42% of reviewers having 50 or fewer employees and 46% having between 51 and 200 employees. The largest industry represented is construction, followed by the automotive sector.

Most metal fabrication software management products are priced on a "per-month" basis, with entry-level pricing plans averaging around $254 per month for 1 to 20 users. This pricing model aligns closely with the budgets of the majority of buyers who have contacted us in the past year (74%). Premium and advanced system subscriptions start around $1,475 per month. [2]

First-time buyers should begin evaluating with a budget, number of users, specific use cases, and necessary integrations in mind. Be sure to consult with key stakeholders on a list of questions to help you evaluate systems based on your needs. Our experienced advisors, Bryan Dengler, Adrian Cantu, and Saul Sanchez, share the following questions to get you started:

Can your system manage and optimize production scheduling and workflow on the shop floor?

What features does your software offer for tracking material usage and inventory levels?

How does your solution support quality control and compliance with industry standards?

Does your software provide real-time data and analytics to monitor production performance and efficiency?

Can your system integrate with our existing tools and software, such as CRM or accounting systems?

With so many vendors out there, picking the right one can feel overwhelming. This guide will walk you through the key components of metal fabrication software and provide step-by-step advice on choosing the best solution for your practice.

If you would prefer to speak with one of our experienced MRP software advisors like Dengler, Cantu, and Sanchez, schedule a call or start a chat with us.

What is metal fabrication software?

Manufacturing businesses (i.e., fabrication shops) need software to handle projects. The software helps them from the time they bid for a contract to the final quality check of the finished product. It also automates inventory tracking, project scheduling, project cost calculation, quoting and bid proposal generation.

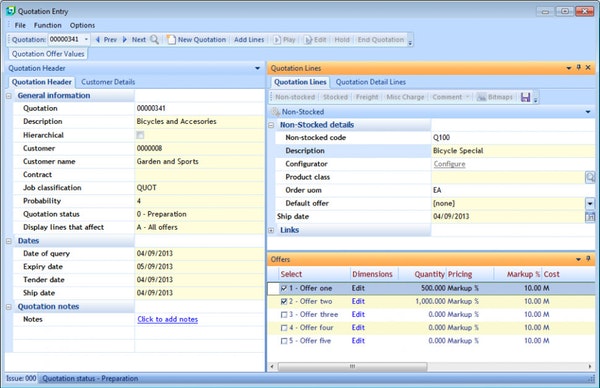

Calculating project costs and creating quotations in Syspro

Metal fabrication companies use all kinds of hardware technologies—from 2D laser cutting and robotic welding to even 3D printing. However, successful metal fabricators go a step further than just using hi-tech equipment. They also use software to ensure that their teams meet production deadlines and maintain high standards of quality.

Known as metal fabrication software, and part of the larger category of manufacturing systems, these solutions help metal fabricators manage different business operations. A feature of metal fabrication software is inventory management that's used to track materials and equipment located in different facilities.

Small businesses that use metal fabrication software will see tangible benefits such as better production planning, faster creation of bid proposals and optimal equipment utilization. The software will also help you eliminate the use of spreadsheets, which are prone to manual errors and waste a ton of employee time.

Features of metal fabrication software

In this section, we have shortlisted the wide-ranging features of manufacturing systems. These are the most common functionality that small businesses can expect in metal fabrication software.

Feature | Description |

Production planning and management | Understand the status of existing work orders, or assign new ones to employees, on visual dashboards. Also, plan job completions using Gantt charts. |

Document management | Create a centralized file repository of the drawings of product models, change orders, request for information (RFI) and other project-related documents. |

Inventory management | Automatically sort and track raw materials, stocked items, work-in-progress (WIP) items and finished products using serial or lot numbers. |

Estimating and quoting | Create project cost summaries by automatically calculating labor and materials costs. Use this information to generate bid proposals. |

Materials management | Calculate the requirement of materials and track the usage of equipment for the optimal utilization of equipment and materials. |

While these features are common to most metal fabrication tools, there could be variations in the depth of functionality and ease of use. Also, different vendors offer different integration options. For this reason, it's essential that you fully explore a tool's functionality to assess whether or not it meets your specific business requirements.

How to choose the best metal fabrication software

Step 1: Determine the type of buyer you are

Getting the right metal fabrication software for your business means analyzing the size of your organization and your software budget. To help you understand the different categories of buyers in this market, we have divided them into the following types:

Full-suite buyers: Large fabrication shops that work on varied projects, such as additive manufacturing, and use robotic automation will have complex needs. They want a one-stop solution for all their manufacturing needs. For instance, a full-suite solution will have built-in CAD tools so that designers can create 3D models for custom fabrication requests.

Small manufacturers: These buyers may not need advanced features but are looking to automate their wasteful manual processes. They need an easy-to-use solution that offers inventory management and project tracking so that they can improve their production speed and quality.

Once you identify the category that you fall under, the next step is to think about the type of software you need. Read about these considerations in the next section.

Step 2: Evaluate your key considerations

When you're shopping for software to use in your business, you need to keep certain things in mind such as software deployments and the use of mobile devices. Here are the top considerations to review vendor offerings before you purchase a solution:

Deployment options: For small fabrication shops, the ideal deployment would be in the cloud over on-premise due to the high upfront license costs of the latter. On-premise tools require you to handle software maintenance and data backup on your own. Therefore, opt for a cloud-based tool that has a smaller monthly subscription fee and the vendor is typically responsible for software upkeep.

Integrations offered: Third-party integrations are important for seamless data transfer between different systems. For example, integrating accounting software will help you create detailed financial reports about your profitability over time, while integrating CAD software will help you import 3D images and drawings. In general, integrations become essential to a small business as it grows and needs more complex systems to meet its requirements.

Mobile accessibility: This is important if your employees don't have fixed workstations. For instance, if you have a designer working remotely, then the ability to receive and send drawings on mobile devices makes processes very convenient. Similarly, warehouse workers can log in the information of new inventory from their mobile devices.

If you need guidance, you can chat online now with one of our advisors or schedule a phone call. You can get tailored recommendations about software that best fits your unique metal fabrication needs.

Understanding metal fabrication market trends

Among the many trends affecting the manufacturing industry, here are some of the most important ones:

Build complex prototypes with 3D printing: Fabrication shops have many uses of metal 3D printing systems that can be integrated with CAD software. This helps them quickly print prototypes and small parts with complicated designs. The technology is especially beneficial for custom fabrication businesses that cater to a wide array of industries such as aerospace and healthcare.

Track inventory easily with smart tagging: Advancements in inventory tagging, such as radio frequency identification (RFID), have solved many challenges of tracking and managing the records of equipment and materials. For instance, a business can monitor the status and availability of equipment remotely with RFID tags. This technology helps metal fabrication shops optimize the stocking of their inventory and prevent theft.

Automate equipment maintenance with Internet of Things (IoT): Manufacturing businesses can use IoT in many ways. For instance, install sensors connected to the internet at the site for automated equipment monitoring. Instead of employees manually checking the health of different systems, the sensors will constantly fetch data and automatically send alerts for any maintenance requirements. With predictive maintenance, businesses can prolong the life of equipment and prevent accidents.

About our contributors

Author

Olivia Montgomery is an associate principal analyst at Software Advice, covering program and project management with a focus on the strategic alignment of IT and operations to optimize digital transformation. Drawing from her experience as a former IT PMO leader and her background in humanities studies, Olivia delivers data-driven insights that empower business leaders to drive business growth through projects.

Olivia’s research and analysis is informed by nearly 200,000 authentic user reviews on Software Advice and over 10,000 interactions between Software Advice software advisors and project management software buyers. Olivia also regularly analyzes market sentiment by conducting surveys of project managers and PMO leaders so she can provide the most up-to-date and helpful information to small and midsize businesses purchasing software or services.

Her expertise is featured in Forbes, Bloomberg, CIO Dive, and TechRepublic, as well as in podcasts, such as The Digital Project Manager. Recently, she presented her research on emotional intelligence (EQ) and decision-making at PMI's Global Summit conference, shedding light on the crucial role of EQ in driving project success. When she's not analyzing tech trends, you can find Olivia horseback riding or re-watching Jurassic Park.

Editor

Parul Sharma is a content editor at Software Advice with expertise in curating content for various niches, including SaaS, digital marketing, and search engine optimization. With over half a decade of experience in content writing and editing, Parul has the expertise to simplify complex terms into engaging, valuable content for targeted audiences.

She completed her graduation and post-graduation in English literature from Delhi University and was awarded the Dr. Asha Sahni Memorial Award for being the highest scorer in her graduating class. Parul has contributed to the news, lifestyle, education, and health verticle of DNA India, India’s premier media channel.

Outside of work, she can be found curating healthy recipes, coloring in mandala books, and spending quality time with her family.

Advisors

Adrian Cantu is a software advisor. He joined Software Advice in 2022, and is based in Austin, TX.

Adrian works directly with small business leaders to connect them with best fit software providers. He assesses the technology needs of small businesses seeking manufacturing, distribution, fleet management, and professional services software. He has a background in sales and has worked in the service industry.

Adrian’s favorite part of being a software advisor is when the buyer sees the value in the service provided and expresses how appreciative they are.

Bryan Dengler is a senior advisor. He joined Software Advice in 2022, and is based in Austin, TX.

As part of the software advisor team, Bryan helps professionals from a wide range of industries who are seeking accounting, project management, manufacturing, learning management, and supply chain software. He provides a shortlist of personalized technology recommendations based on budget, business goals, and other specific needs.

Bryan’s favorite part of being a software advisor is knowing he’s made a valuable difference in a buyer’s life with each advising session he holds.

Saul Sanchez is a senior advisor. He joined Software Advice in 2019, and he is based in Austin, TX.

Saul works directly with small business leaders to connect them with best fit software providers. He assesses the technology needs of small businesses seeking a wide variety of software, including business intelligence, inventory management, manufacturing, and supply chain tools. Through one-to-one conversations, Saul provides a short list of potential matches.

His favorite part of being a software advisor is experiencing a buyer’s relief when they discover how much time and energy he’s saved them by helping narrow down the list of many possible options on the market.

Sources

Software Advice reviews data: Software Advice reviews are collected from verified users for individual software products. For this report, we analyzed reviews from August 19, 2023 to August 19, 2024.

Software Advice software pricing data: Only products with publicly available pricing information and qualified software products within the category, as of November 29, 2023, are included in the pricing analysis. Read the complete methodology.

Metal Fabrication FAQs

- What software do steel fabricators use?

Steel fabricators typically use a variety of software tools to assist with design and project management, with metal fabrication software being the top system manufacturers contact us about. According to our analysis of products with high market demand and reviews, the full-suite solution, Striven, had the highest overall rating from verified reviewers on Software Advice for metal fabrication software.

- What are the three 3 types of metal fabrication?

Metal fabrication mainly involves three key processes: cutting, bending, and assembling. Cutting breaks metal into smaller shapes, bending changes its form without removing material, and assembling combines metal parts using methods like welding or bolting to create the finished product. Metal fabrication software is used to help track and manage these processes.

- Which software is best for sheet metal design?

The best software for sheet metal design is typically a full-suite manufacturing resource planning (MRP) system. According to our analysis of products with high market demand and reviews, Striven has the highest overall rating from verified reviewers on Software Advice for metal fabrication software. If you’re looking for a 3D computer-aided design (CAD) tool, Striven also offers integrations with these systems.

- What is fabrication software?

Fabrication software is a specialized tool designed to help plan, design, and manage metal fabrication projects. The broader category of metal fabrication software helps streamline these processes including inventory management, purchase order management, and managing bill of materials. This software improves efficiency, reduces errors, and enhances productivity by automating various tasks in the fabrication process, from design to delivery.

- Which software is best for steel estimation?

The best software for steel estimation is a building information modeling (BIM) system. According to our analysis of products with high market demand and reviews, Striven had the highest overall rating from verified reviewers on Software Advice for metal fabrication. Striven’s estimation features help with steel estimation, creating more accurate and efficient calculations for material needs.