Best Distribution software of 2026: which is right for you?

- Popular Comparisons

- FrontRunners

- Buyers Guide

Compare Products

Showing 1 - 25 of 225 products

Compare Products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Average Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

Alphabetically (A-Z): Sorts listings by product name from A to Z.

Focus X is an all-inclusive enterprise resource planning (ERP) system that helps you connect every aspect of your business opera...Read more about Focus X

Focus X's Best Rated Features

See All

Focus X's Worst Rated Features

See All

NetSuite is an AI-powered cloud-based business management suite that incorporates ERP, financial management, CRM and eCommerce f...Read more about NetSuite

NetSuite's Best Rated Features

See All

NetSuite's Worst Rated Features

See All

Cin7 Omni is a highly configurable inventory management and order management solution with built-in EDI and integrations to all ...Read more about Cin7 Omni

Cin7 Omni's Best Rated Features

See All

Cin7 Omni's Worst Rated Features

See All

Versa is Modern all-in-one Cloud ERP software created for fast growing inventory heavy manufacturing, distribution, and e-commer...Read more about Versa Cloud ERP

DigitBridge is a digital commerce operations system designed specifically for small-to-medium sized businesses (SMBs). DigitBr...Read more about DigitBridge

NECS entrée is an on-premise ERP solution designed explicitly for food distributors. It offers functionality for inventory manag...Read more about Entree

SAP S/4HANA Cloud is a cloud-based and on-premise enterprise resource planning (ERP) solution. It is suitable for small, midsize...Read more about SAP S/4HANA Cloud

SAP S/4HANA Cloud's Best Rated Features

See All

SAP S/4HANA Cloud's Worst Rated Features

See All

Microsoft Dynamics 365 Business Central is a cloud-based enterprise resource planning (ERP) software solution designed for midsi...Read more about Dynamics 365 Business Central

Dynamics 365 Business Central's Best Rated Features

See All

Dynamics 365 Business Central's Worst Rated Features

See All

Wherever you are on your digital journey, growing the profits of your business can be made easier with the right platform to kee...Read more about ERP One

AcctVantage ERP is a distribution and manufacturing software solution. It helps businesses streamline their operations. The soft...Read more about AcctVantage ERP

Infor Distribution SX.e is an easy-to-use, modern ERP solution purpose-built for the highly specialized, core processes of distr...Read more about Infor Distribution SX.e

Prophet 21 gives distributors real-time inventory insights to always know what's in stock and available to promise customers. Th...Read more about Epicor Prophet 21

A2000 Apparel Management Software is the best ERP for your fashion business of design, manufacturing, inventory, warehouse, and ...Read more about A2000

A2000's Best Rated Features

See All

A2000's Worst Rated Features

See All

Accolent ERP is an enterprise resource planning (ERP) and enterprise resource management (ERM) software suite designed for busin...Read more about Accolent ERP

Brightpearl is a complete retail operating system for brands, retailers, and wholesalers, designed to scale with fast-growing eC...Read more about Brightpearl

Brightpearl's Best Rated Features

See All

Brightpearl's Worst Rated Features

See All

Sage 300cloud (formerly Sage Accpac) is an enterprise resource planning (ERP) software system that serves small and medium-size ...Read more about Sage 300

Sage 300's Best Rated Features

See All

Sage 300's Worst Rated Features

See All

Striven is a cloud-based enterprise resource planning (ERP) solution suitable for many industries and organizations of all sizes...Read more about Striven

Striven's Best Rated Features

See All

Striven's Worst Rated Features

See All

Sage X3 is a powerful ERP software solution designed for midsized national and global manufacturers, distributors, and after-sal...Read more about Sage X3

Sage X3's Best Rated Features

See All

Sage X3's Worst Rated Features

See All

Kechie Distribution Management efficiently manages internal and external resources. Suited for growing businesses, the managemen...Read more about Kechie

Kechie's Best Rated Features

See All

Kechie's Worst Rated Features

See All

Datacor ERP (formerly Chempax) is an integrated enterprise resource planning (ERP) and customer relationship management (CRM) ap...Read more about Datacor ERP

Datacor ERP's Best Rated Features

See All

Datacor ERP's Worst Rated Features

See All

Fidelio ERP is a cloud-based business management platform built for small and midsize manufacturers, wholesalers, distributors, ...Read more about Fidelio ERP

No reviews yet

recommendations

Epicor Vision enterprise software is a powerful solution for automotive aftermarket parts distributors ready to deliver superior...Read more about Epicor Vision

No reviews yet

recommendations

Infor M3 is a cloud-based ERP solution for global manufacturers and distributors with complex value chains. It offers analytics ...Read more about Infor M3

SnapFulfil by Synergy Logistics is a cloud-based Warehouse Management System (WMS) designed to give distribution and fulfillment...Read more about SnapFulfil WMS

SnapFulfil WMS's Best Rated Features

See All

SnapFulfil WMS's Worst Rated Features

See All

Prospect CRM is the #1 Stock-Aware CRM built specifically for B2B wholesalers, distributors, and manufacturers who sell products...Read more about Prospect CRM

Prospect CRM's Best Rated Features

See All

Prospect CRM's Worst Rated Features

See All

Popular Comparisons

Your Guide to Top Distribution Software, August 2025

Software Advice uses reviews from real software users to highlight the top-rated Distribution products in North America.

Learn how products are chosenExplore FrontRunners

“Usability” includes user ratings for Functionality and Ease of Use.

“Customer Satisfaction” includes user ratings for Customer Support, Likelihood to Recommend and Value for Money.

Reviews analysis period: The reviews analysis period spans two years and ends the 15th of the month prior to publication.

Buyers Guide

This detailed guide will help you find and buy the right distribution software for you and your business.

Last Updated on January 27, 2025Distributors sit in the middle of the supply chain, providing a connection between manufacturers and, ultimately, consumers. Distribution software can help manage operations by tracking products and terms for multiple suppliers and multiple customers, including such diverse things as economic order quantities and cooperative advertising dollars, for both suppliers and customers.

There are nearly 100 wholesale distributor software vendors on the market. We wrote this buyer’s guide to help buyers better understand what to look for when assessing distribution software reviews in this market.

Here’s what we’ll cover:

What Is Distribution Software?

Common Features of Distribution Software

What Is Distribution Software?

Common functions of distribution software include:

Operations management

Accounting

Inventory management

Customer relationship management

Order management

Purchasing

Warehouse management

Front counter operations

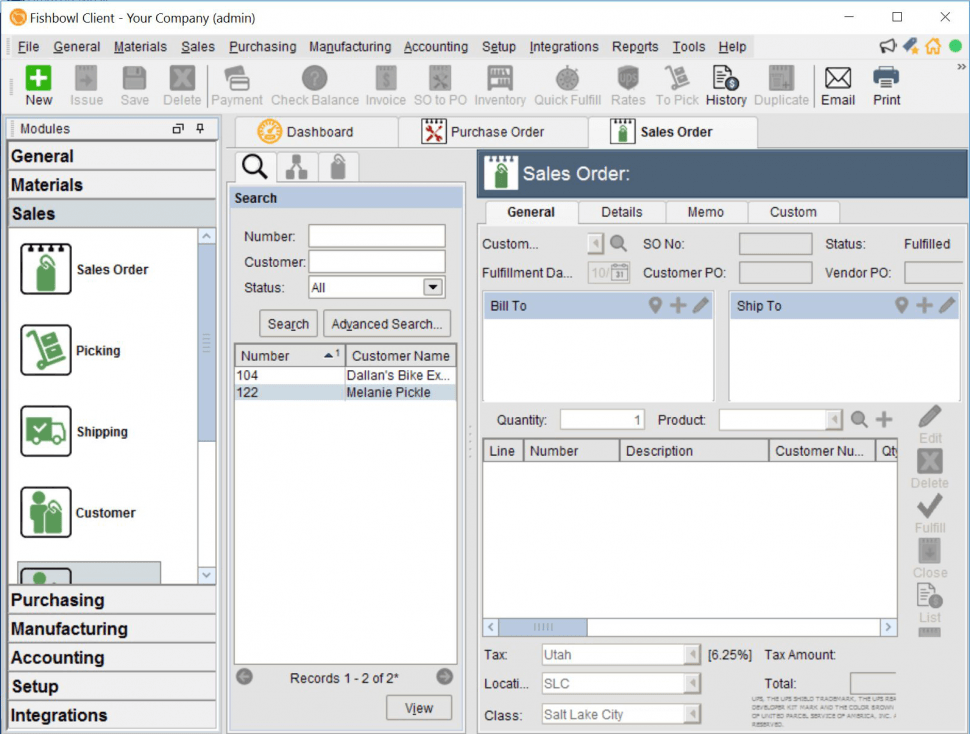

Sales order in Fishbowl

While small operations can use generic accounting and inventory management systems, distributors and distribution centers (DCs) require the special functions available in distribution management systems.

Common Features of Distribution Software

Front counter operations | Automates the point of sale if the distributor does pick up sales for wholesale or even retail. Functions include order processing, tax calculations and receipt printing. Interfaces with inventory and customer relationship systems. Example vendors include Microsoft, Counterpro and Activant. |

Customer management | Used to maintain customer contact information, preferences, reorder points and credit information. Functions include generating mailing lists, maintaining sales history and tracking co-op sales. Example vendors include SAP, Oracle and SugarCRM. |

Order management | Prepares bids, prepares quotes and processes customers orders. Functions include quote to order, preparing shipping information, creating return materials authorizations. Example vendors include SAP, NetSuite and Microsoft. |

Purchasing & procurement | Used to order inventory and track discounts offered. Functions include preparing purchase orders, tracking economic order quantities and preparing receiving reports. Example vendors include Gilliani, Geneva and Microsoft. |

Inventory management | Used to count, track, receive and locate parts and materials. Functions include tracking assets, processing advance notifications, tracking inventory value and tracking reorder points. Example vendors include Sage, Epicor and Oracle. |

Warehouse management | Tracks the quantity and stock of inventory items within the warehouse. Warehouse distribution management functions include slotting analysis, preparing pick information and location tracking. Examples vendors include Royal4, S2K, HighJump and Geneva. |

Distribution accounting | Automates the general ledger, accounts receivable, accounts payable and other accounting functions with special emphasis on the unique requirements of distributors. Functions include keeping ledger balances, tracking client debt and calculating available discounts. Example vendors include SAP, Oracle, Microsoft and Intuit. |

Demand management | Used to adjust inventory levels according to fluctuations in the demand forecast to ensure that supply coordinates with demand. It will include functionality to track customer delivery schedules, manage customer rebates and process order returns. Example vendors include SAP, Epicor and NetSuite Distribution. |

Used by distribution companies to transfer or trade documents from computer to computer. Mostly used by businesses needing to share data between outside organizations. Example vendors include SAP, Epicor and Microsoft. |

What Type of Buyer Are You?

Before evaluating distributor software, you’ll need to determine what type of buyer you are. Over 90 percent of buyers fall into one of these four groups:

Full-suite buyer. These buyers value the seamless integration of data and processes that comes from having one system for all functions. For example, a full-suite system for accounting, customer relationship management and inventory management can turn quotes automatically into orders and then generate picking lists, shipping labels and invoices. These buyers favor complete distribution management software suites like Oracle, SAP, Sage ERP or Microsoft Dynamics AX.

Multiple warehouse operations buyer. These buyers run multiple facilities and need to track and balance inventories over a geographical area. The buyers require software that can balance inventory between warehouses while strategically placing it closest to the probable customers. The system must give both overall enterprise data as well as breaking down each operation. It must track customer and vendor accounts, and make sure customer accounts are consolidated even if the customer orders from different locations.

Departmental buyer. These buyers are specialists for firms that have an internal distribution network. They may only sell to their own outlets, but they must contend with multiple suppliers, inventory issues, competing corporate customers and transportation decisions similar to commercial distributors use. As such, they should evaluate software for wholesale distribution companies that can support multiple departments.

Small business buyer. These buyers may work for distributors or wholesalers or may have a distribution component as part of their business. They usually have smaller numbers of clients, suppliers and inventory and may include some assembly or production components but still face the same basic issues as large-scale distributors. These buyers are often using paper-based systems or general wholesale distribution software small business distributors typically use like Intuit or Peachtree.

Benefits and Potential Issues

As distributors feel pressures from increasing demands to restock as the economy recovers and to reassert value in the supply chain, they need concrete benefits to justify system expenses.

Lower total logistics cost. Since distribution management systems let managers get a more realistic view of inventory costs, they can take steps to increase the overall costs. For example, it might be more cost effective to buy a slightly more expensive product that has better packaging that takes substantially less shelf space.

Increased profitability. Combining information from TLC analysis and slotting analysis, objects that are picked together often, can be shelved next to each other. This reduces the overall labor involved in picking, although the costs for each individual item is constant.

Improved customer service. In addition to fulfilling orders more quickly and accurately, inventory systems work with customer relationship management and order management systems to project customer’s needs, notifying representatives to contact customers with suggested orders and recommending related goods. Ideally, your distribution business software interfaces directly with the customer’s order system allowing orders to be placed and processed automatically.

Improved vendor relations. Distributors can use the information and analysis from the inventory system to become better customers to their suppliers by analyzing trends and placing orders that do not have to change in the middle of fulfillment. Better orders, improved receiving processes and integration with supplier systems all work to make vendor transaction run smoother.

Reduced compliance costs. Many distributors are subject to strict governmental and insurance regulations because of the materials they carry in inventory. Distribution management software can generate much of the required compliance documentation as a consequence of ordering and receiving materials and equipment.

The chief issue with wholesale distribution software systems is lag time. Even when the various modules and components share a database, which is the norm now, there is a time lag between when events occur and when they are recorded. This can lead to improper decisions. Most systems are written with the assumption that changes are made and transmitted instantly; reality is different.

For example, when a customer places an order, ideally the value of that order should be immediately moved from current inventory and appear in accounts receivable. What really happens is that the order is entered, the inventory is tagged as “Allocated," the pick list is generated, the inventory is picked and packaged. If the shipment is free on board (FOB) origin, once the order is picked up, the items should be removed from inventory. The inventory system’s recorded location of the inventory at any given time has important tax and floor planning considerations, which can affect cash flow.

The other limitation is expense. Even basic warehouse distribution software systems use bar codes, mobile readers and a wireless network. More advanced systems require an extensive infrastructure that potentially requires every location on every shelf to have some form of hardware installed.

Market Trends to Understand

In the age of on-demand, custom-built products; overnight shipping and Internet disintermediation, the distribution sector is under pressure to reestablish its value proposition and increase efficiency. One of the ways distributors can do this is by utilizing advanced features included in software for distribution business needs.

Total logistics cost modeling. Traditionally, inventory was costed by adding its unit cost to its shipping cost. Total logistics cost (TLC) looks at all expenses related to acquiring, transporting and storing inventory. This includes things such as labor costs, the amount of shelf space required and even allocated overhead costs. For example, if two items cost the same and weigh the same, but one is much larger than the other, the larger item will require more storage space and will have a higher TLC.

Pick to light technology. Pick to light (PTL) is a paperless picking technology. Instead of printing a pick list, arrays of lights on the ceiling and shelving indicate the location of the items to be picked. Digital displays on the shelf give the quantity to pick. PTL is incorporated into warehouse management or inventory management software and can reduce operations costs in the warehouse.

Intelligent inventory tagging. The use of one-dimensional bar coding for equipment and inventory tagging is well established in manufacturing systems. Recent systems use radio frequency identification (RFID), which can be read remotely to check inventory levels and to confirm equipment availability. Other systems use two-dimensional bar codes which contain descriptive information in addition to an identifier like a part number.

Advanced slotting analysis. Advanced slotting analysis uses historical inventory information, picking trends and warehouse shelving layout information to determine the most cost-effective placement of inventory in the warehouse. Slotting analysis can also ensure that dangerous items are not stored together, for example, ammonia next to chlorine, which could violate government regulations, insurance restrictions and common sense.